Intensive longitudinal clapboard UHPC box girder bridge

A technology of longitudinal diaphragm and box girder, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of resisting longitudinal positive bending moment, increase transverse bending stiffness, increase bridge dead load and other problems, so as to improve the shear bearing capacity. , The effect of improving longitudinal stiffness and increasing longitudinal stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

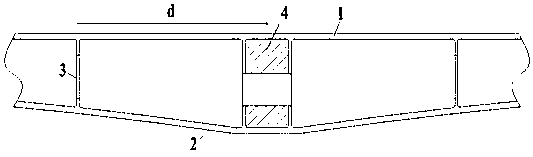

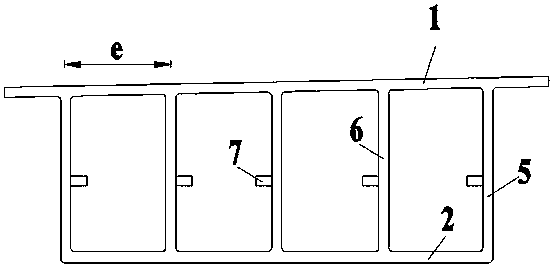

[0029] refer to Figure 1~3 , a UHPC box girder bridge with dense longitudinal diaphragms in this embodiment, including a top plate 1, a bottom plate 2, a web 5, a transverse diaphragm 3, an end transverse diaphragm 4, and three longitudinal diaphragms 6 arranged along the longitudinal direction of the bridge. For the box girder, the web 5 and the longitudinal diaphragm 6 are provided with unilateral longitudinal stiffeners 7 to increase the transverse bending stiffness of the web 5 and the longitudinal diaphragm 6 and prevent lateral buckling.

[0030] The UHPC box girder bridge is provided with an end diaphragm 4 at the support position, the end diaphragm increases the transverse stiffness of the bridge, and can better transmit the force of the support, so as to ensure the transverse stiffness of the box girder and improve the box girder. overall strength of the beam.

[0031] The distance between adjacent medial diaphragms 6 along the width direction of the bridge is 2~5m,...

Embodiment 2

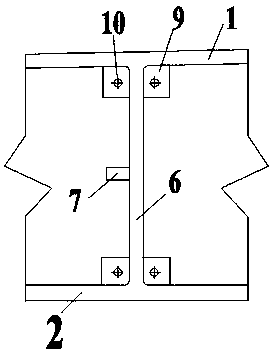

[0037] refer to Figure 4 , compared with Example 1, a kind of UHPC box girder bridge with dense mediastinal plates in this example has the following differences:

[0038] Short longitudinal ribs 8 are provided at the middle part of the adjacent medial diaphragm 6 and the cantilever flange, which effectively improves the longitudinal stiffness of the box girder and reduces the amount of longitudinal prestressed reinforcement 10 .

[0039] refer to Figure 5 , The web 5, the longitudinal diaphragm 6, the short longitudinal rib 8 and the top plate 1 / bottom plate 2 are provided with a prestressed anchor tooth block 9, which is beneficial to achieve a better anchoring effect on the prestressed steel bar 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com