Anchor cable construction method for rectangular top pipe joint connecting and strengthening

A rectangular pipe jacking and construction method technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc. problems, to achieve the effect of reducing maintenance costs in the later period, low overall cost and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

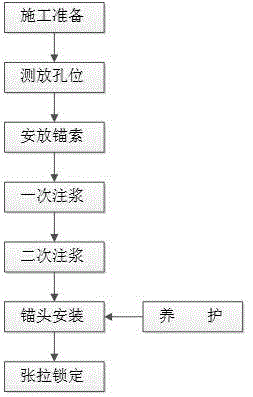

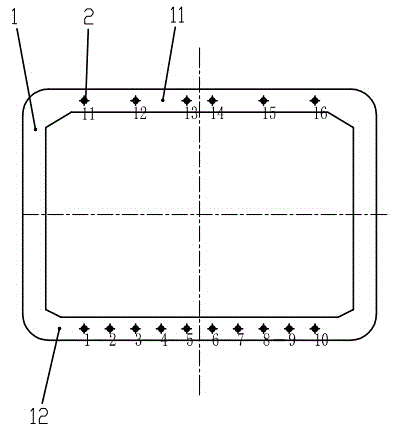

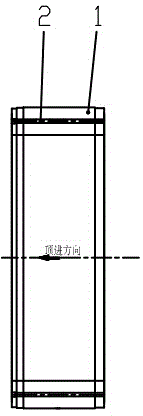

[0034] In this embodiment, the street crossing passage of a large underground shopping mall in a certain area is taken as an example. The street crossing underground passage is constructed using the rectangular pipe jacking method. Pipe jacking may produce lateral unbalanced thrust, so it is necessary to strengthen the longitudinal stiffness of each pipe jacking channel, such as Figure 1 to Figure 6 As shown, this embodiment adopts the anchor cable construction method of connecting and reinforcing rectangular pipe jacking pipe joints, including the following steps:

[0035] (1) Construction preparation: understand the geological conditions and hydrological conditions of the strata where the rectangular pipe jacking is located, and make preparations for construction tools and planning for the construction process;

[0036] (2) Measuring and releasing hole position: Correspondingly open a plurality of prestressed through holes on the end face of the rectangular pipe jacking pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com