High-speed railway nose-shaped metal sound barrier unit board

A high-speed railway and sound barrier technology, applied in buildings, noise absorption devices, etc., can solve the problems of damp failure of sound-absorbing materials, poor sound-absorbing effect, easy to float into rainwater, etc. Maintenance cost, the effect of not being susceptible to moisture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

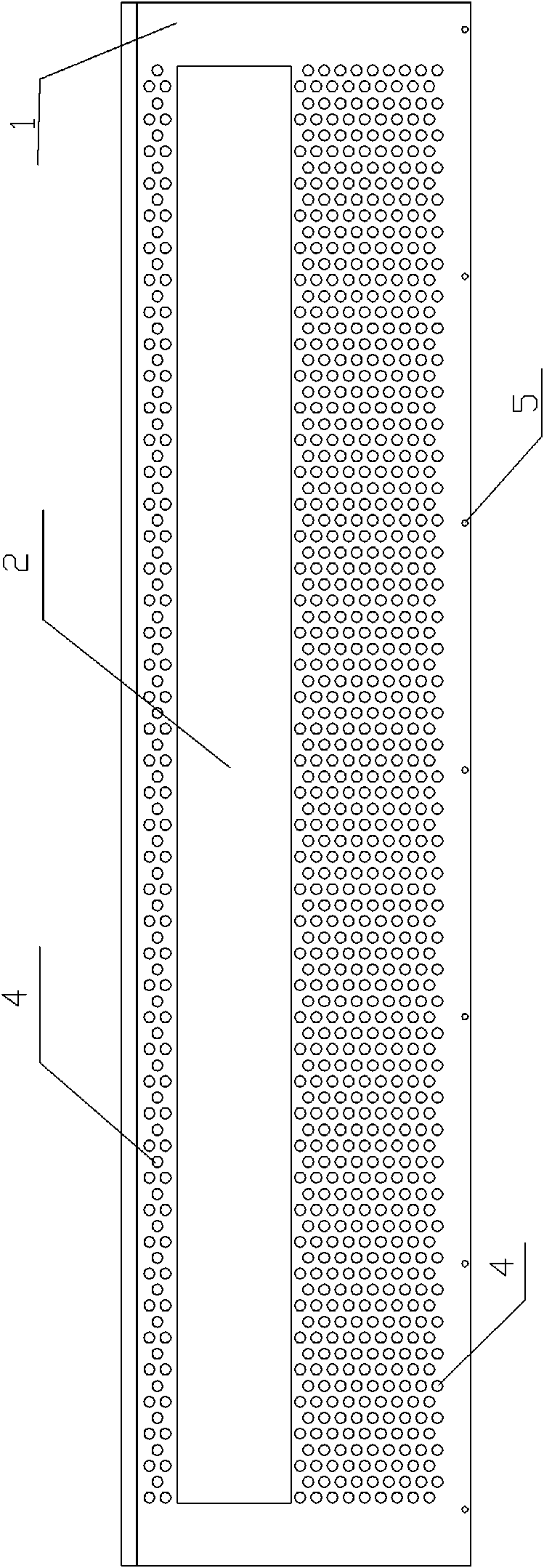

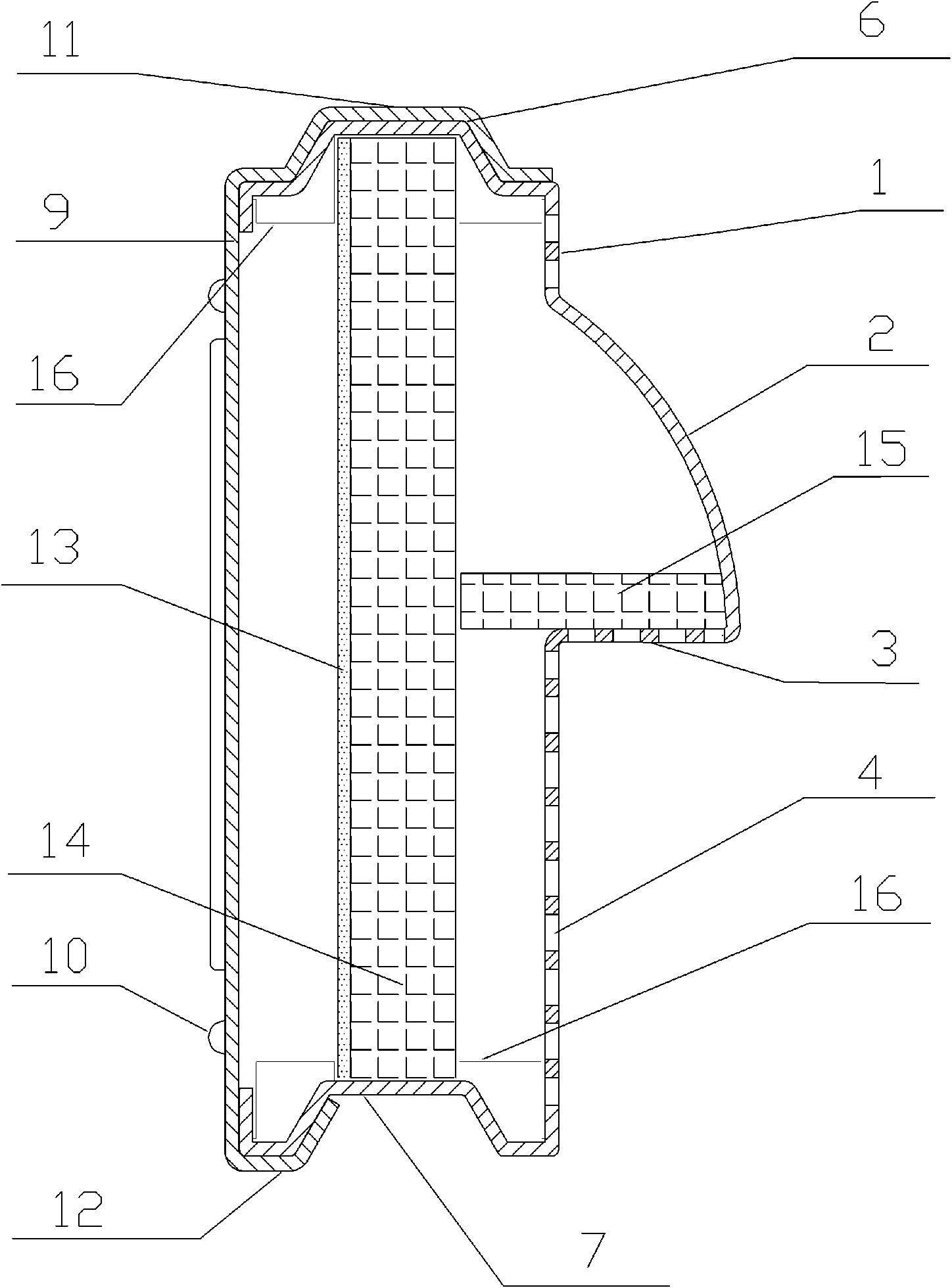

[0023] figure 1 , image 3 As shown, a specific embodiment of the present invention is a high-speed railway nose-shaped metal sound barrier unit plate, including an aluminum alloy panel 1, an aluminum alloy back panel 9, and a gap between the aluminum alloy panel 1 and the aluminum alloy back panel 9. Fiber cement board 13, sound-absorbing material 14 and sound-absorbing material fixing device 16 are characterized in that: the middle and upper part of the aluminum alloy panel 1 is a nose-shaped protrusion 2 protruding outward; The directional part is arc-shaped, and the bottom 3 in the transverse direction is provided with sound-absorbing material 15; the bottom 3 of the nose-shaped protrusion 2 and the parts other than the nose-shaped protrusion 2 on the aluminum alloy panel 1 are provided with sound holes 4.

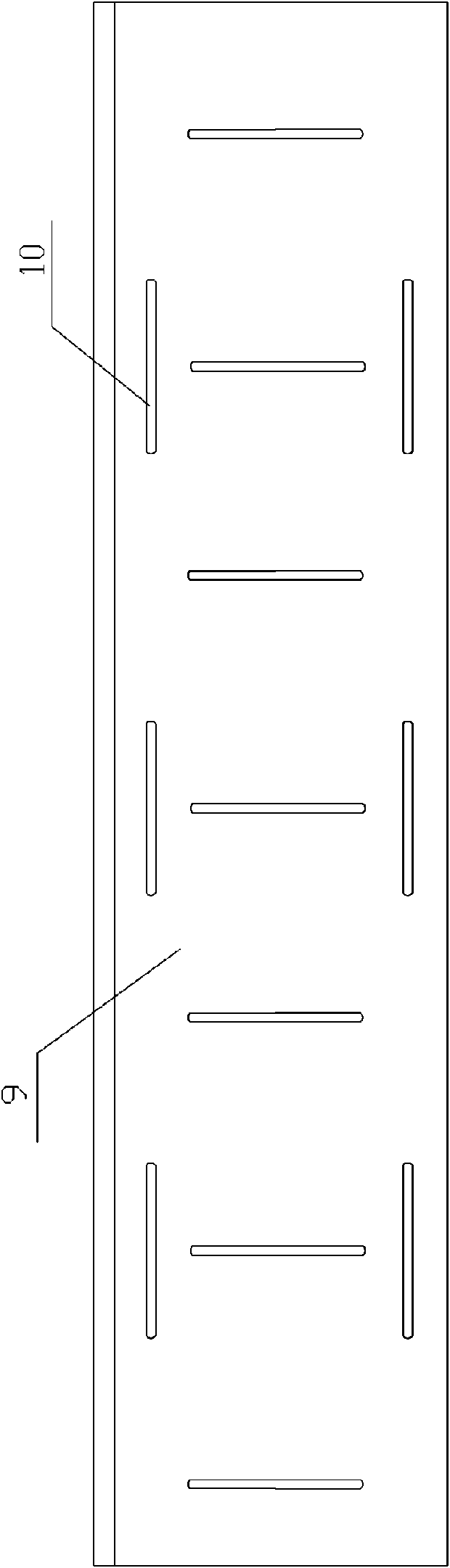

[0024] figure 2 It is shown that the aluminum alloy back plate 9 of this example is pressed with longitudinal ribs 10 .

[0025] figure 1 It is shown that the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com