Reinforcing system and method for reinforced concrete column

A technology of reinforced concrete columns and aluminum alloys, which is used in bridge reinforcement, building maintenance, erection/assembly of bridges, etc., can solve problems such as affecting the continued use of building structures or bridge structures, large residual deformation of reinforced concrete columns, and brittle failure of reinforced columns. , to achieve the effect of rapid recovery of structure and function, reduction of residual deformation, and improvement of energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in further detail below in conjunction with accompanying drawing:

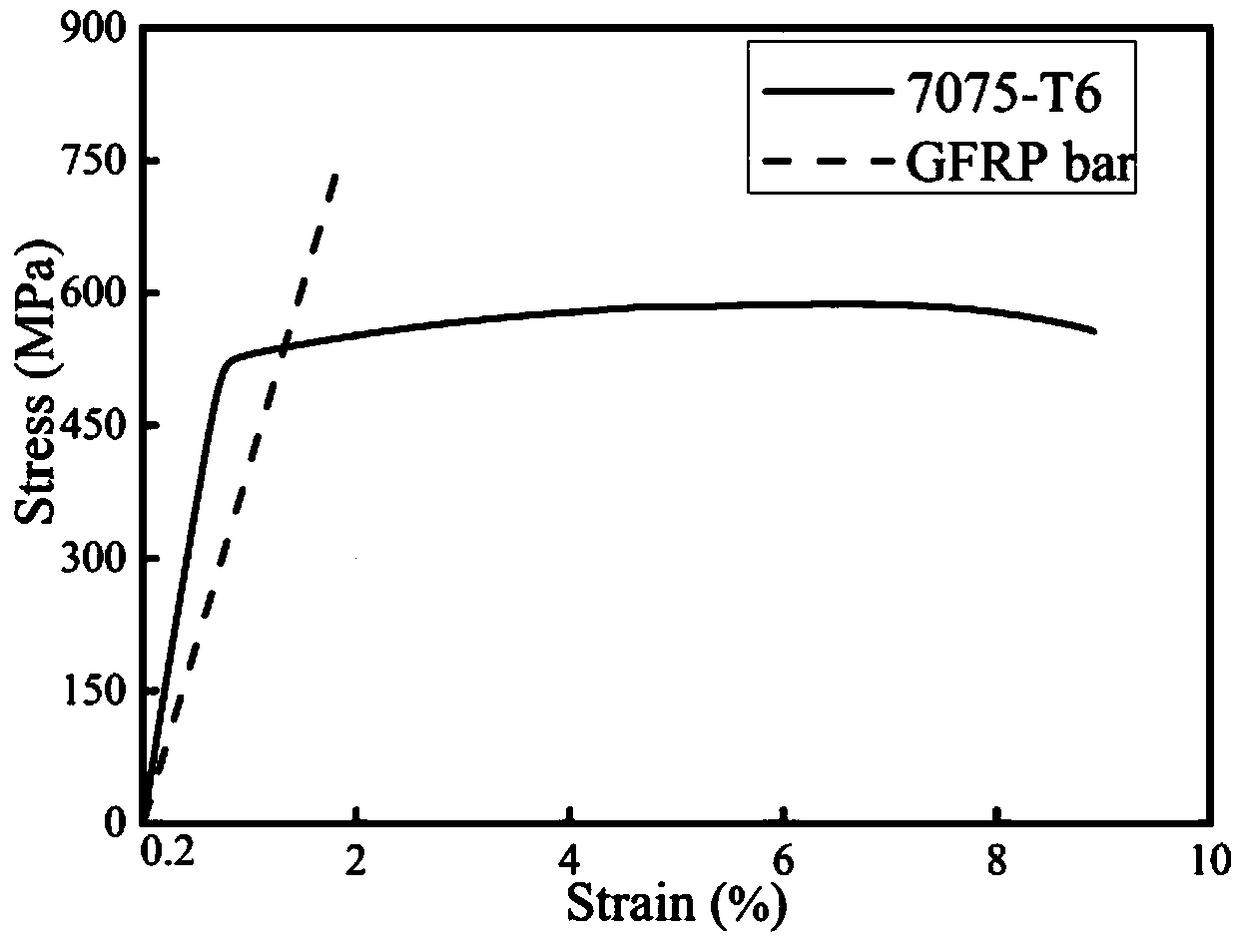

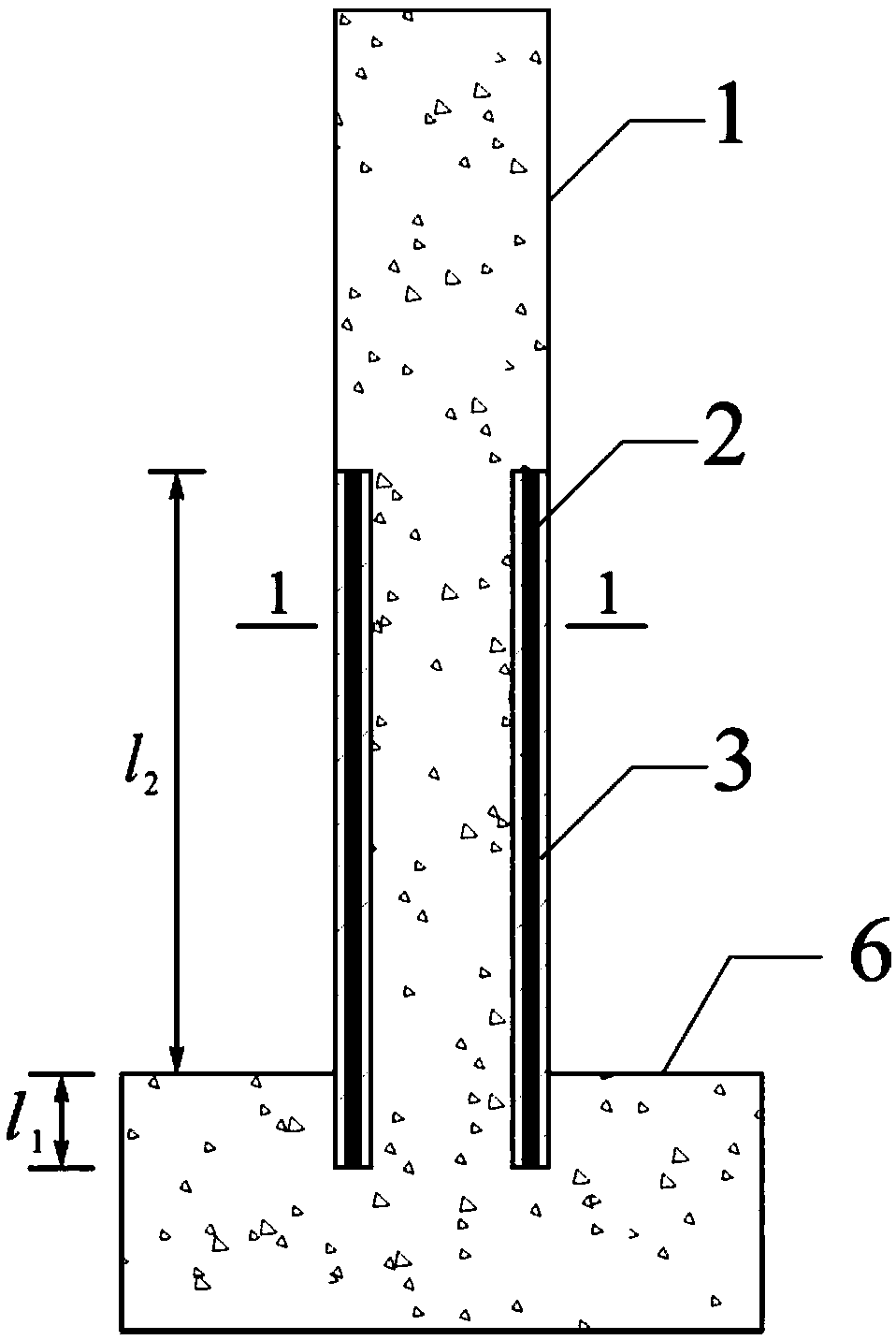

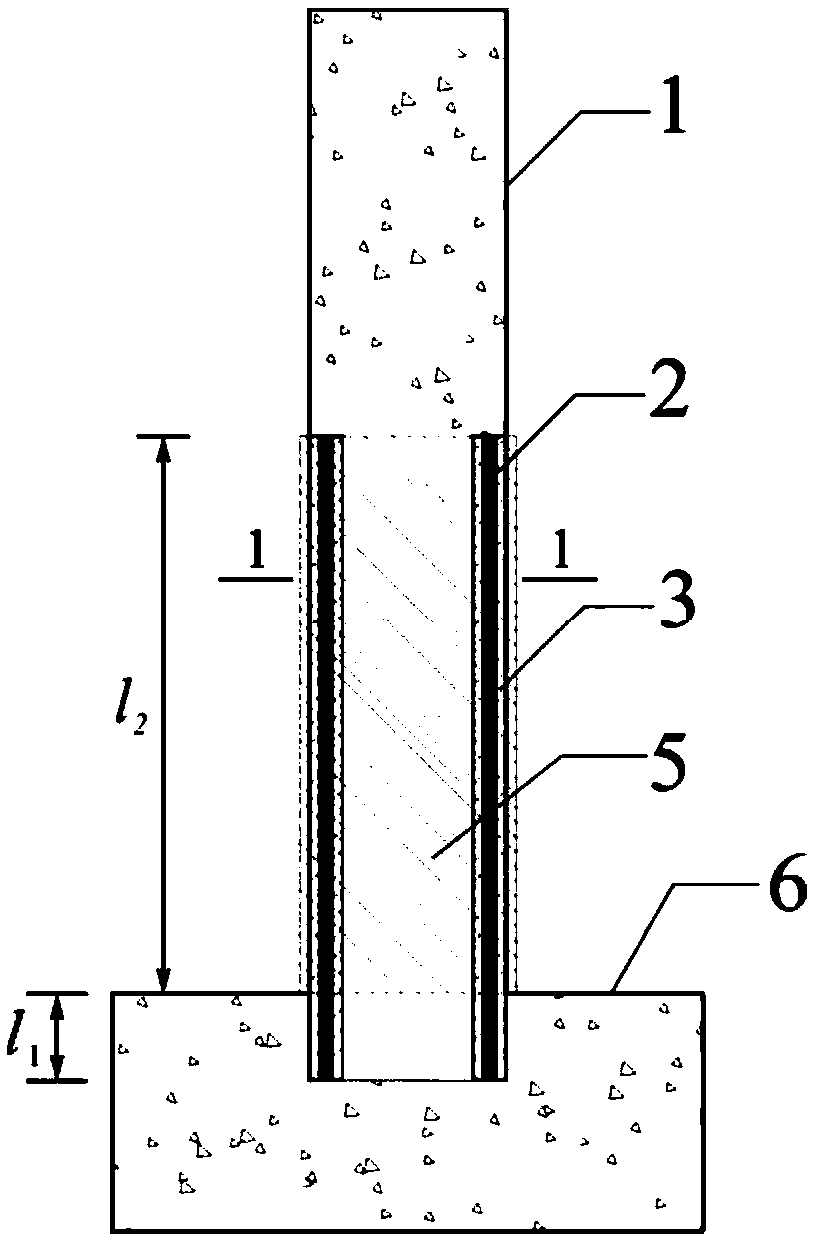

[0044] Such as Figure 1 to Figure 6 As shown, a reinforced concrete column reinforcement system, the lower end of the reinforced concrete column is provided with a foundation, including aluminum alloy bars 2 and filling materials 3, and a vertical reinforcement slot 4 is provided in the protective layer of the side wall of the reinforced concrete column 1 , the reinforcement slot 4 does not damage the steel bar structure in the reinforced concrete column 1, the aluminum alloy bar 2 is placed in the reinforcement slot 4, the gap between the aluminum alloy bar 2 and the reinforcement slot 4 is filled with a filler material 3, and the reinforcement slot 4 The length of the part located in the foundation 6 is l 1 , the reinforcement slot 4 is located at the upper end of the foundation 6 and the length is l 2 , l 1 The length is 15 ~ 20d, d is the diameter of the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com