Plating liquid for plating micro-crack nickel and use thereof

A technology of micro-crack nickel and electroplating solution, applied in the field of electroplating solution, can solve the problems affecting the overall appearance of the car, prone to corrosion, customer dissatisfaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

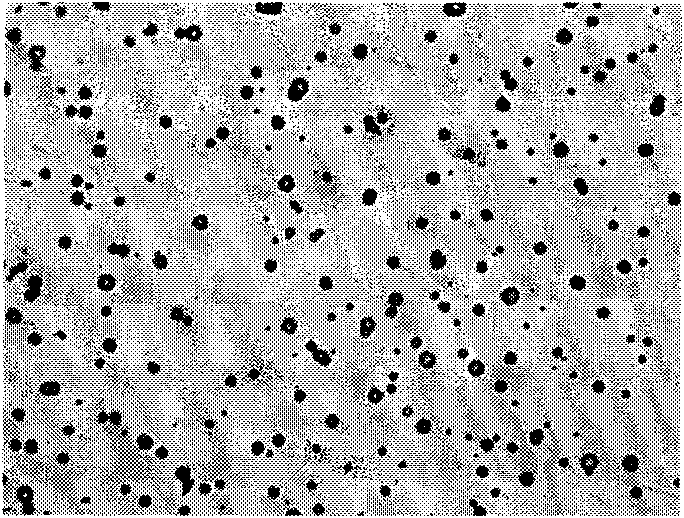

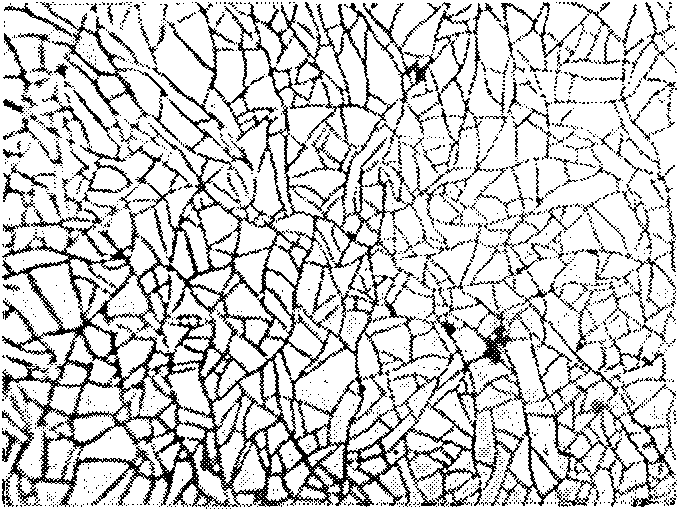

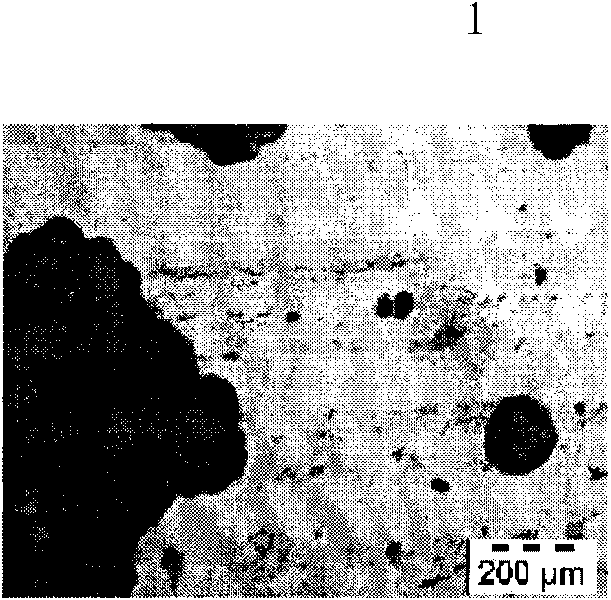

Image

Examples

Embodiment 1

[0088] A pre-treatment metallization, through the pre-treatment of ordinary ABS plastic electroplating process, the process of forming a chemical nickel layer about 2 microns thick in the chemical nickel tank, the parts change from plastic parts to metal parts, so that the subsequent electroplating can proceed smoothly.

[0089] B bright copper, put the parts metallized through the pretreatment of A into the bright copper tank, and the composition and process specifications of the electroplating solution are:

[0090] Copper Sulfate 200g / L

[0091] Sulfuric acid 50 g / L

[0092] Chloride 60 mg / L

[0093] 1541 MAKE UP 10ml / l

[0094] 1541 LEVETER 0.3 ml / l

[0095] 1541 MAINTENANCE 0.3 ml / l

[0096] Temperature 26°C

[0097] Time 41 minutes

[0098] Current density 3A / dm 2

[0099] Using the phosphor copper ball as the anode, copper is deposited on the surface of the electroplating piece by direct current electrolysis to form a bright copper layer with a thickness of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com