Method for prolonging life of pump shells and blades by carrying out laser strengthening micro-cracks

A micro-crack and laser-strengthening technology, applied in metal material coating process, coating and other directions, can solve the problem of difficult to guarantee the bonding degree of repair material and substrate, uneven thickness of welding layer, uneven machining allowance, and heat-affected zone of surfacing technology. It can improve the fatigue strength and service life, improve the fretting fatigue resistance, and improve the repair effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] This embodiment will be described in detail below in conjunction with the accompanying drawings.

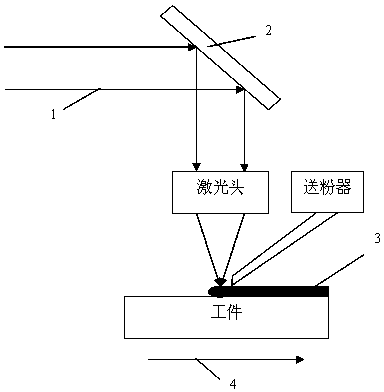

[0030] This method mainly consists of four process steps. The first step is to determine the damaged parts, perform non-destructive testing on them, and locate surface cracks (or damage) and defects; the second step is to figure 1 As shown, the laser cladding process is performed after pretreatment of cracks (or damage) and defects: the laser beam 1 passes through the mirror 2 to complete the convergence and transformation of the beam, and the powder feeder delivers the cladding metal powder to the preset position. Then the laser beam acts on the surface of the metal powder and the material through the laser working head, and the workpiece moves from left to right ( figure 1 (shown in the moving direction 4 of the workpiece) moves at a constant speed to form the cladding layer 3, and finally completes the cladding repair on the surface of the damaged part; the third step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com