A Quaternary Polynomial Speed Planning Algorithm for Spline Interpolation

A speed planning algorithm and quartic polynomial technology, applied in automatic control devices, feeding devices, digital control, etc., can solve problems such as discontinuous jerk, affecting processing quality, and sudden acceleration changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

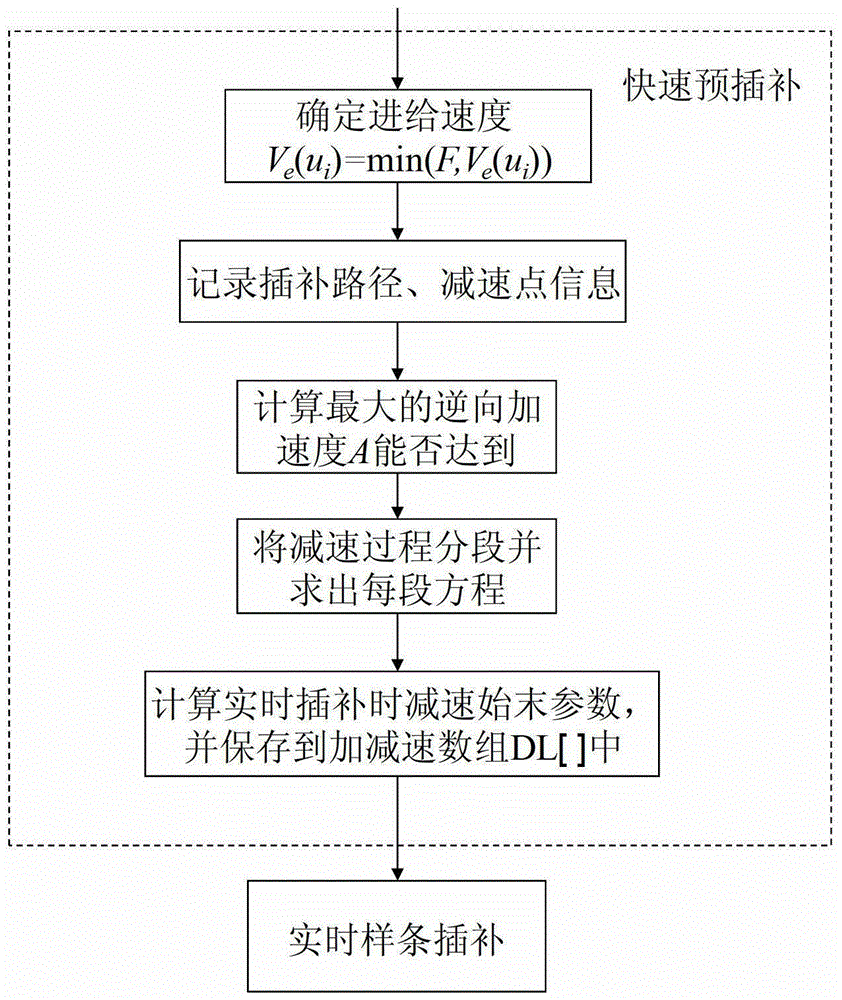

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0075] In the present embodiment, the inventive method is simulated and verified on a PC. The programming software used is MicrosoftVisual C++6.0, and the C language is used to write the program. The spline curve selected here is a NURBS (Non-UniformRational B-Spline) curve.

[0076] The main technical imputation parameters of the test environment are as follows:

[0077] Operating system: Microsoft Windows XP

[0078] CPU: Pentium(R) Dual-Core

[0079] Main frequency: 2.93GHz

[0080] Memory: 2G

[0081] The interpolation parameters of the CNC system are as follows:

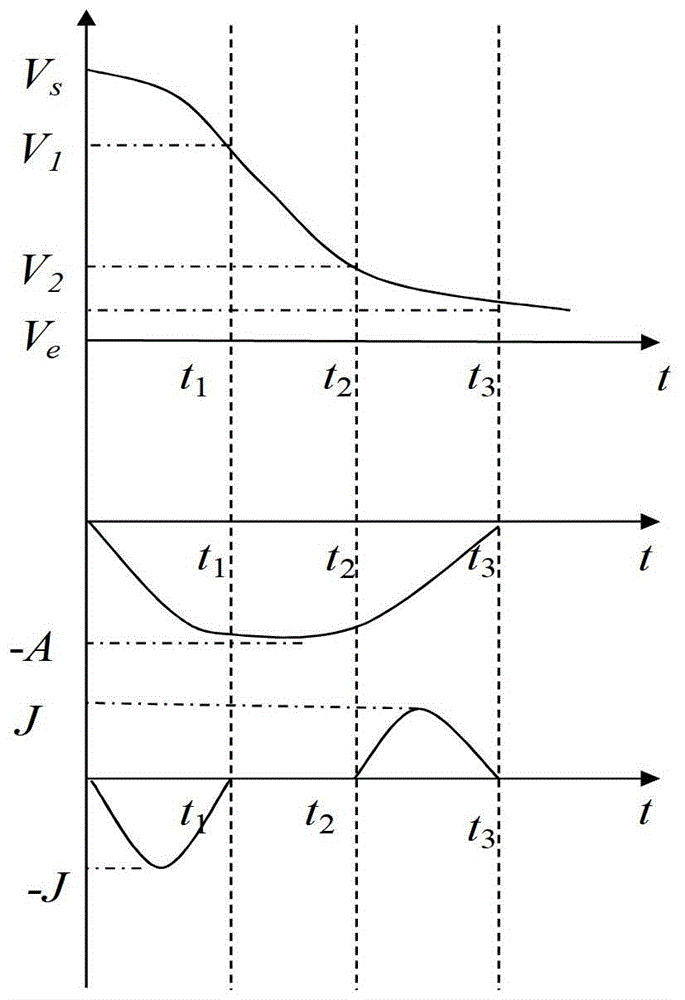

[0082] Feed rate F=200mm / s;

[0083] Maximum acceleration A=0.005m / s 2 ;

[0084] Maximum jerk J=0.0004m / s 3 ;

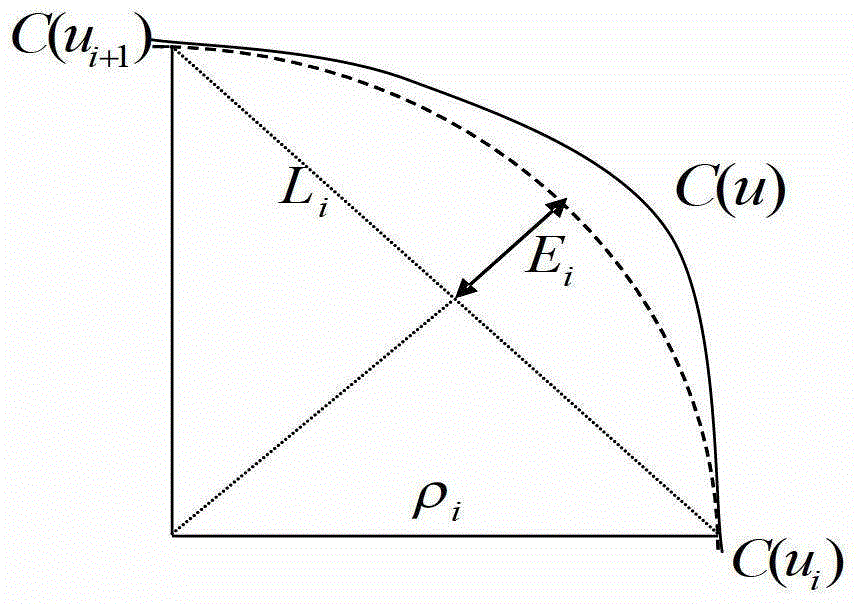

[0085] Maximum chord height error ER=0.0005mm;

[0086] Interpolation period T=2ms;

[0087] This embodiment takes the processing of a typical workpiece program "inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com