Integrally cast core mechanism with built-in steel wire rope coated with polyurethane

A technology of polyurethane and steel wire rope, which is applied in the field of built-in steel wire rope and covered with polyurethane integrated casting type core mechanism, which can solve the problems of increased core pulling force, core fracture, core joint and mandrel easy to break, etc., to ensure the material Continuity and uniformity, improvement of axial rigidity, and effect of ensuring contour accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

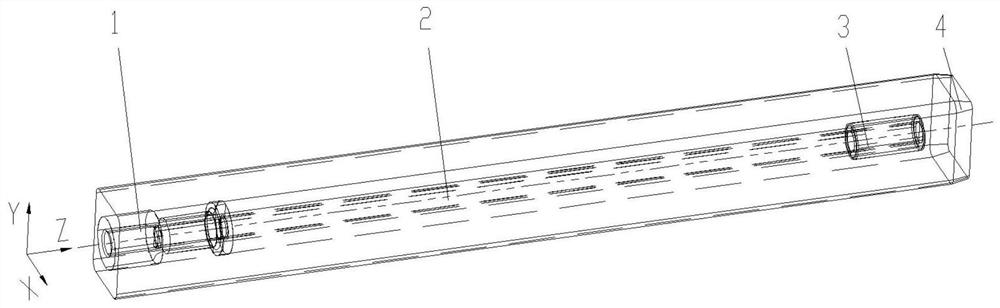

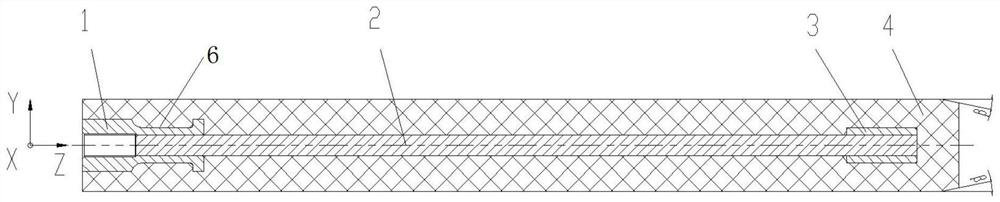

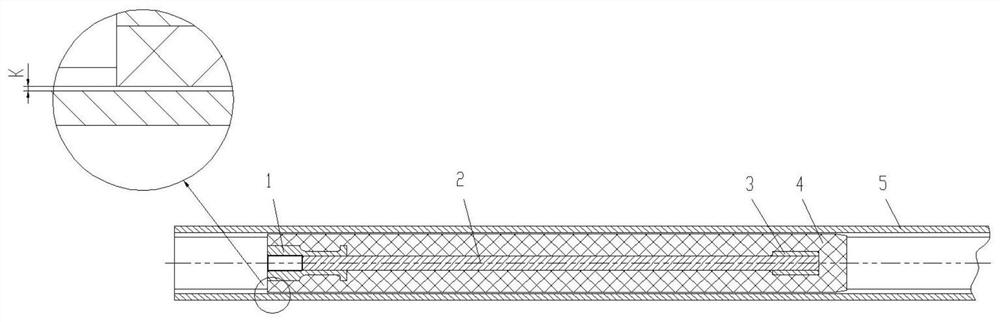

[0026] refer to Figure 1-2 , a polyurethane integral casting core mechanism with a built-in steel wire rope outer covering includes a built-in flexible skeleton and a polyurethane outer layer 4, the polyurethane outer layer 4 is covered on the outside of the built-in flexible skeleton, and the built-in flexible skeleton includes a transition joint 1, a steel wire rope 2, and a buckle 3. The head end of the steel wire rope 2 is fixedly connected to the transition joint 1 by crimping; the transition joint 1 is a tubular structure, and the head end of the transition joint 1 is processed with an internal thread structure, which is used as the connection interface with the external plug-in core oil cylinder; the steel wire rope 2 ends The end is fixedly connected with the buckle 3 by crimping; the buckle 3 is embedded in the polyurethane outer layer 4. The core mechanism can be freely bent around the X and Y axes, and cannot be elongated along the Z axis during the bending process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com