Intelligent method for automatically regulating servo parameters for numerical control machine tool

A technology of CNC machine tools and parameters, applied in the field of CNC machine tools, which can solve the problems of reducing the feed speed and failing to guarantee the accuracy of parts contours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

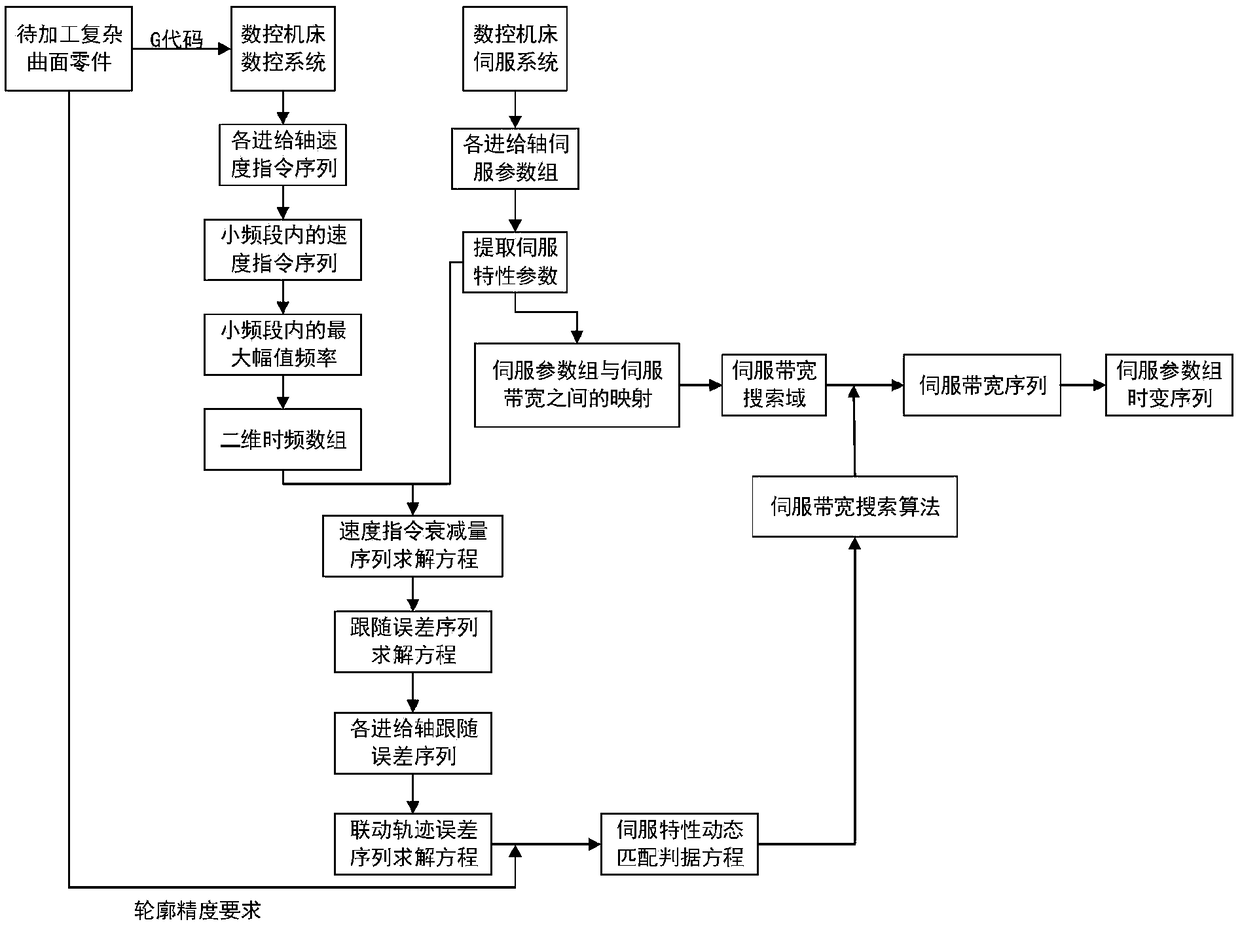

[0054] Such as figure 1 As shown, an intelligent method for autonomously adjusting servo parameters applied to CNC machine tools includes the following steps:

[0055] Step 1), run the G code of the complex curved surface part to be processed in the numerical control system, and collect the speed command sequence output to each feed axis after the numerical control system interpolates;

[0056] Step 2), adopting wavelet transform to carry out time-frequency analysis to each feed axis speed command sequence, transform it into several small frequency bands, construct the speed command sequence in the small frequency band;

[0057] Step 3), adopt discrete Fourier transform to carry out frequency spectrum analysis to the speed instruction sequence in each small frequency band, extract the maximum amplitude frequency in each small frequency band;

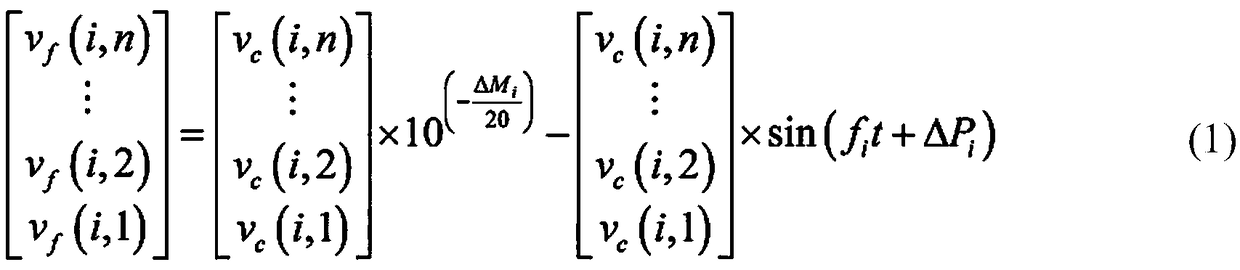

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com