Method for manufacturing cylindrical titanium alloy parts with two ends flanged inwards through forced supplementing

A manufacturing method and flanging technology, which are applied in the field of flanging cylindrical parts and titanium alloy cylindrical parts with flanging at both ends, can solve the difficulties in controlling the shape accuracy of the cold forming process, uneven thickness distribution, and thickness reduction. Thinness and other problems, to achieve the effect of solving uneven thickness distribution, uniform overall thickness distribution, and avoiding springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

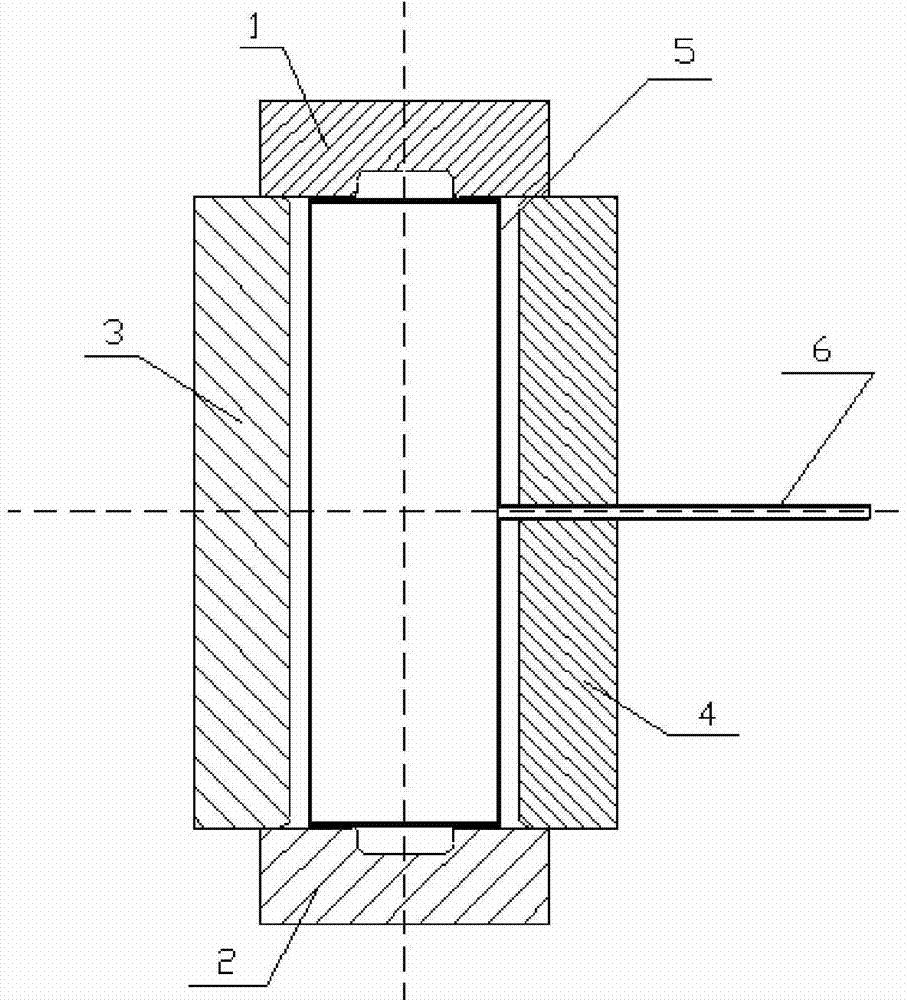

[0038] The specific embodiment is carried out according to the following process steps:

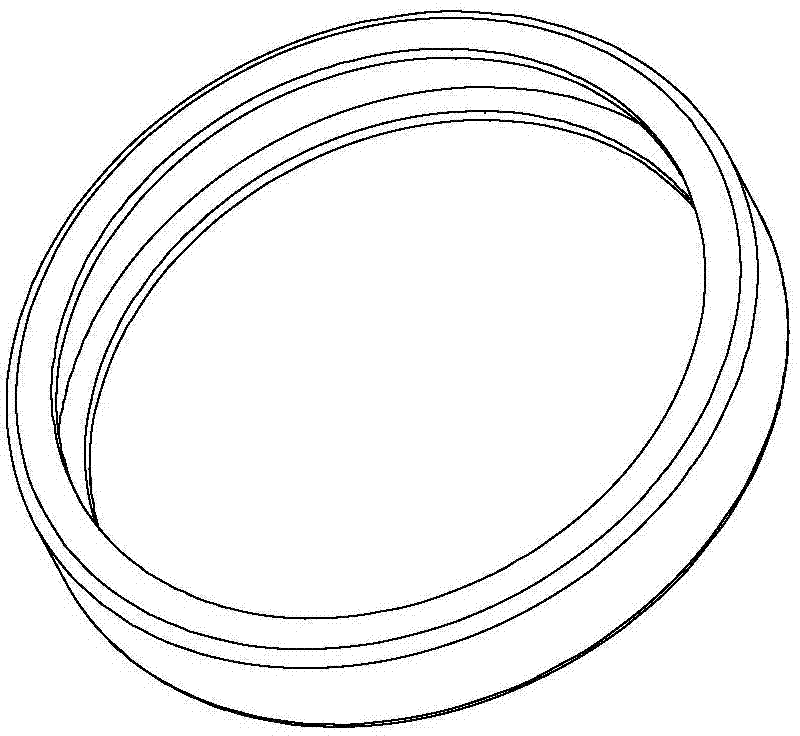

[0039] The first step is to determine the structure and size of the forming blank and unfold the blank: according to the structure of the part, determine that the blank of the inner flanging cylindrical part at both ends is a pipe. Because the diameter of the pipe is large, the titanium alloy pipe is obtained by sheet metal rolling and welding; considering the process The margin, the roundness error in the diameter direction of the titanium alloy after welding, and the thermal expansion rate of the titanium alloy determine that the initial pipe diameter is 325mm, the pipe length is 100mm, and the titanium alloy sheet size after unfolding is 1020mm×100mm, and the thickness is 1.5mm ;

[0040] The second step blanking and sheet coil welding: according to the size of the blank, the blank is cut by laser cutting or numerical control punching; the surface treatment of the cut blank is slag blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com