Coaxial powder feeding and laser forging composite addition and subtraction material manufacturing method and device

A coaxial powder feeding and laser technology, applied in the field of additive and subtractive material manufacturing, can solve the problems of internal quality problems of parts, low dimensional accuracy and efficiency, and achieve the effect of solving air holes, ensuring the contour and surface accuracy of parts, and changing the internal structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

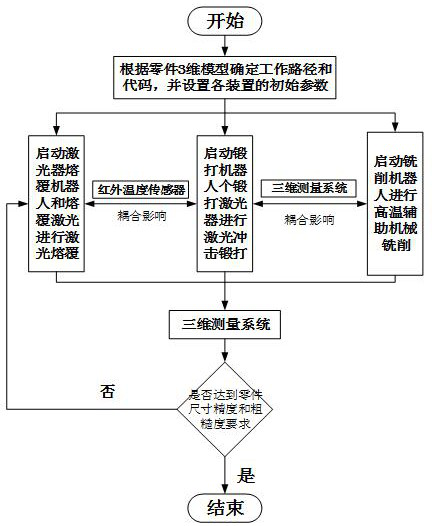

[0033]Such asfigure 1 Shown is an embodiment of the manufacturing method of the coaxial powder feeding and laser forging composite increase and decrease material of the present invention, including the following steps:

[0034]S1. Based on the three-dimensional model of the part, slice the part into several layers, generate the laser cladding path, impact forging path, plane and profiling milling path codes for each layer, and initially design the laser cladding process parameters of the manufacturing device ;

[0035]S2. Start the continuous laser generator 18, and the cladding robot 14 drives the coaxial powder feeding cladding laser head 13 to perform cladding according to the laser cladding process parameters in step S1;

[0036]S3. According to the laser cladding process parameters and the temperature data of the infrared temperature sensor 12 in step S2, the laser forging process parameters are analyzed, and the formed area of each layer is laser forged through the forging laser head...

Embodiment 2

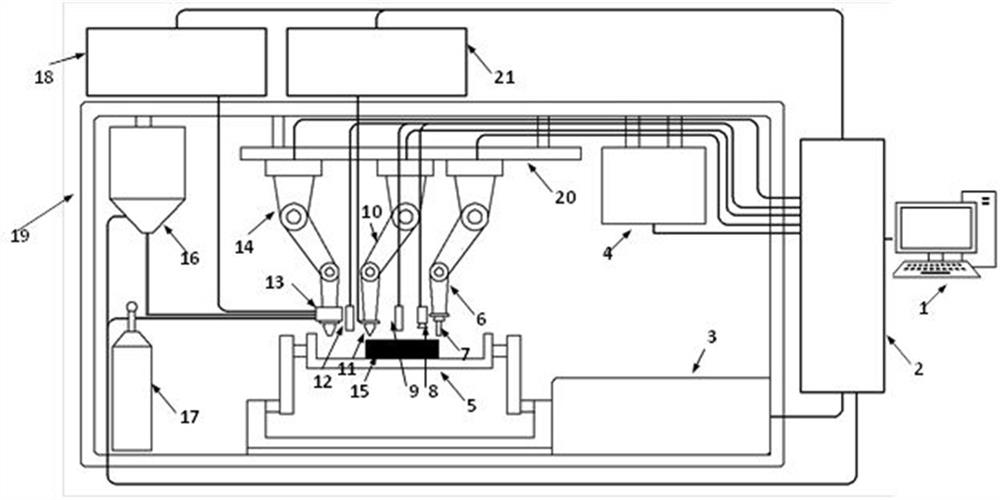

[0046]Such asfigure 2Shown is the first embodiment of the coaxial powder feeding and laser forging composite adding and reducing material manufacturing device, including a central control system 2 and a table power system 3 connected to the central control system 2, a cladding system, and a laser forging system , Milling system, computer 1, workbench power system 3 is connected with a five-axis workbench 5, cladding system, laser forging system, and milling system are connected with a support frame 20, and the workpiece 15 is set on the five-axis workbench 5; The power system 3, the cladding system, the laser forging system, and the milling system are covered with a casing 19, and the casing 19 is also provided with a tool magazine 4 connected to the central control system 2.

[0047]In the implementation of this embodiment, the central control system 2 is provided with three control modules respectively controlling the cladding system, the laser forging system, and the milling system....

Embodiment 3

[0052]This embodiment is an application of the method of the first embodiment in manufacturing an aircraft engine blisk, and includes the following steps:

[0053]S1. Determine the three-dimensional model of the blisk through the computer 1, slice the parts of the disc body and the blades separately, plan the laser cladding path, impact forging path, and milling path for each layer respectively to generate a milling cladding robot 14 The movement code of the forging robot 10, the milling code of the milling robot 6, and the movement code of the five-axis worktable 5, to initially determine the laser cladding process parameters;

[0054]S2. Manufacturing of the disk body: According to the planned path of the disk body, the laser beam is generated by the continuous laser generator 18 and transmitted to the coaxial powder feeding and cladding laser head 13 through the optical path. At the same time, the powder storage tank 16 and the gas storage tank 17 are sent through The powder / gas pipe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com