Selecting and matching method for plunger assembly with check ring

A plunger and retaining ring technology, applied in the field of plunger assembly matching, can solve the problems of oil film failure on the surface of the sliding shoe, inflexible plunger assembly, poor spherical surface profile, etc., and achieves low requirements for processing skills and improves service life. , the effect of stable size and shape error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

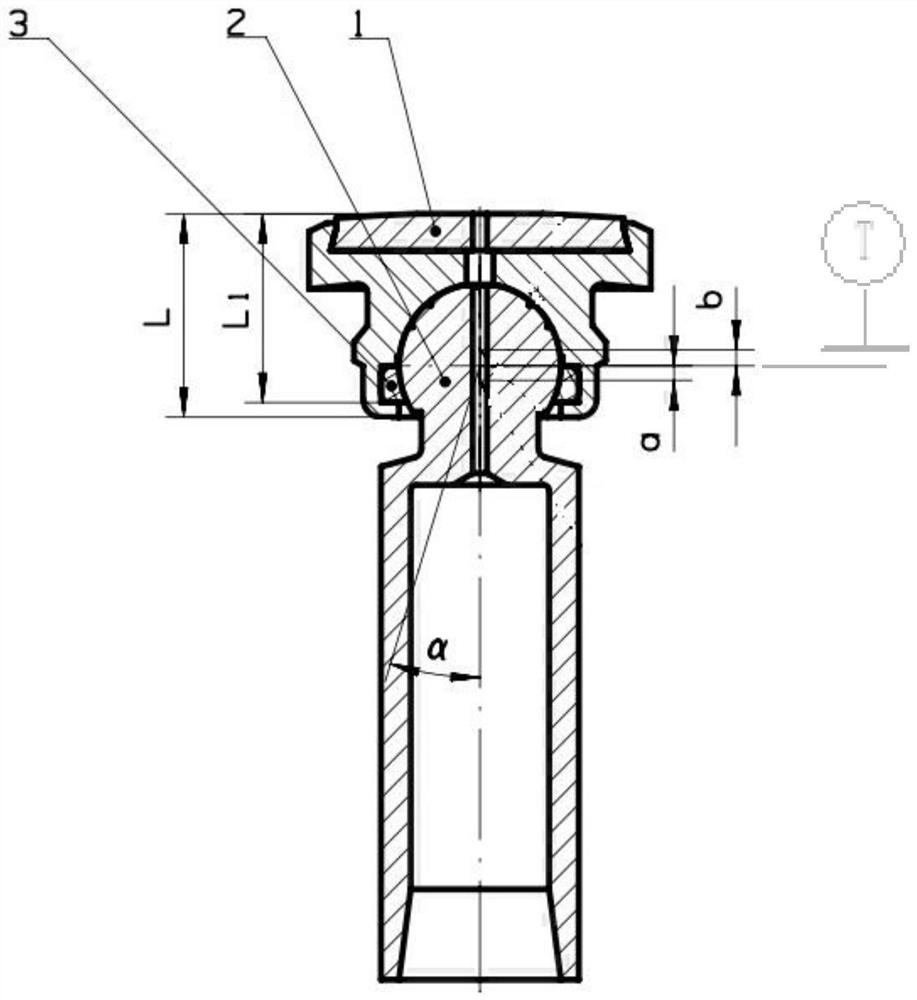

[0034] The invention provides a matching method of a plunger assembly with a retaining ring, the method comprising the following steps:

[0035] 1) Prepare the sliding shoe, retaining ring and plunger;

[0036] 2) Process the inner spherical surface of the shoe and measure the size of the inner spherical surface of the shoe, specifically:

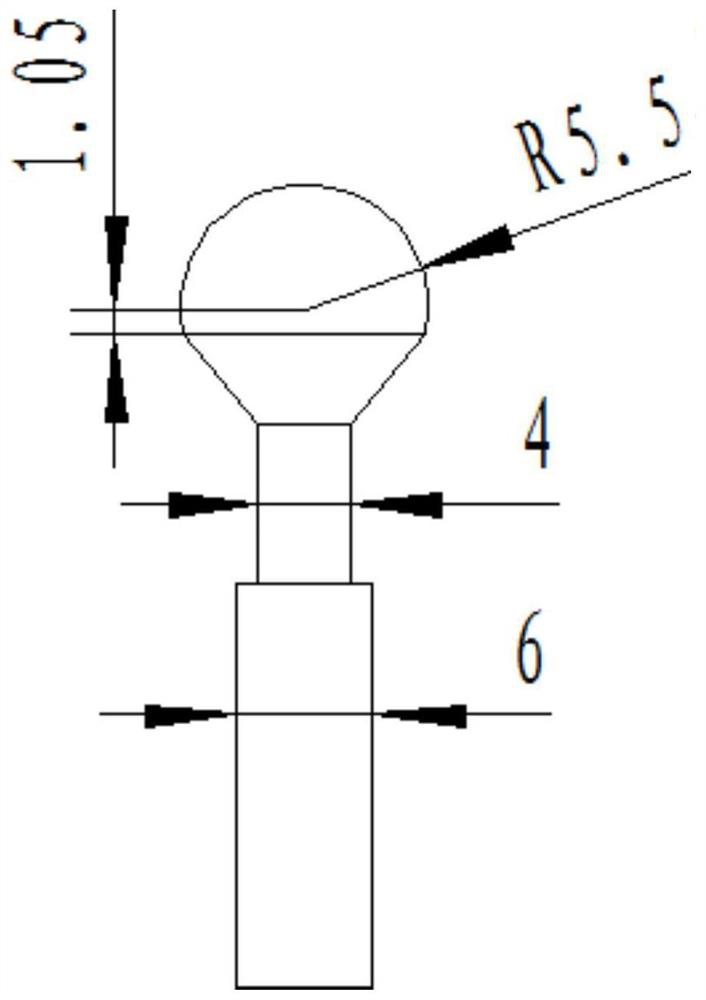

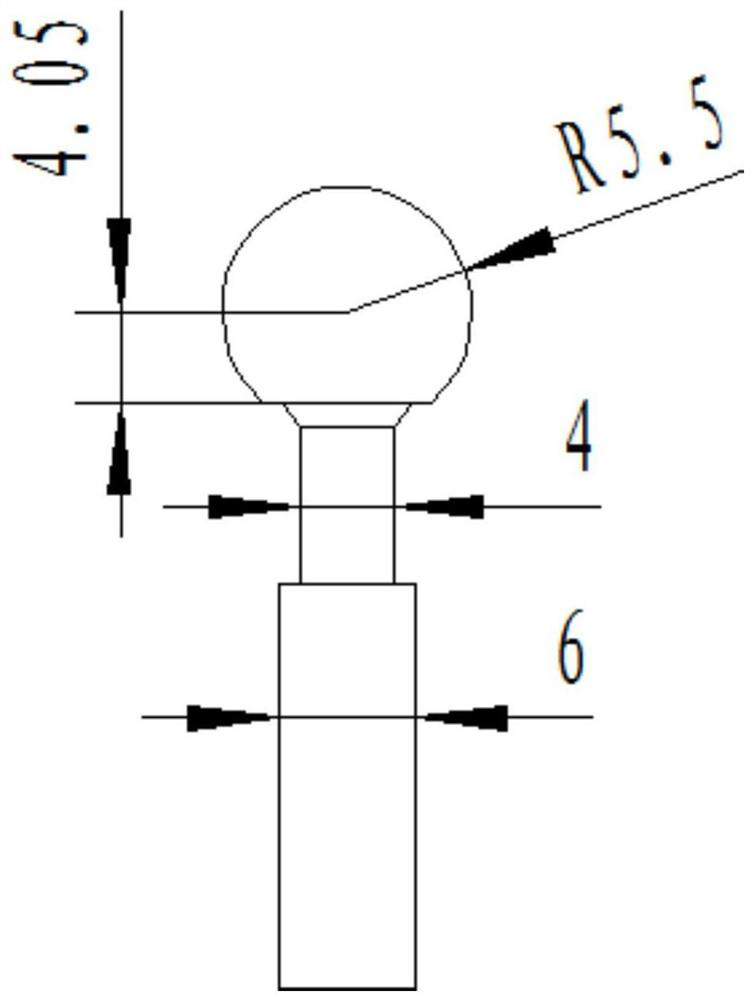

[0037] 2.1) Prepare the sliding shoe grinding tool and the sliding shoe grinder; the sliding shoe grinding tool includes the grinding tool ball head and the connecting rod connected with the grinding tool ball head; the grinding tool ball head is in a hemispherical structure overall, and the lower edge of the hemispherical structure is Larger than a hemispherical surface; the shoe grinder includes a grinder head and a grinder rod connected to the grinder head; the grinder head is in a hemispherical structure as a whole, and the lower edge of the hemispherical structure is slightly smaller than the spherical edge when the shoe swings to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com