Composite material large wing surface I-shaped stringer wallboard forming tool

A technology of composite materials and long trusses, which is applied in the field of forming tooling structures for large-scale airfoil I-shaped long truss panels made of composite materials, and can solve the problems of low accuracy of shape contour and large deviation of long truss axis positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

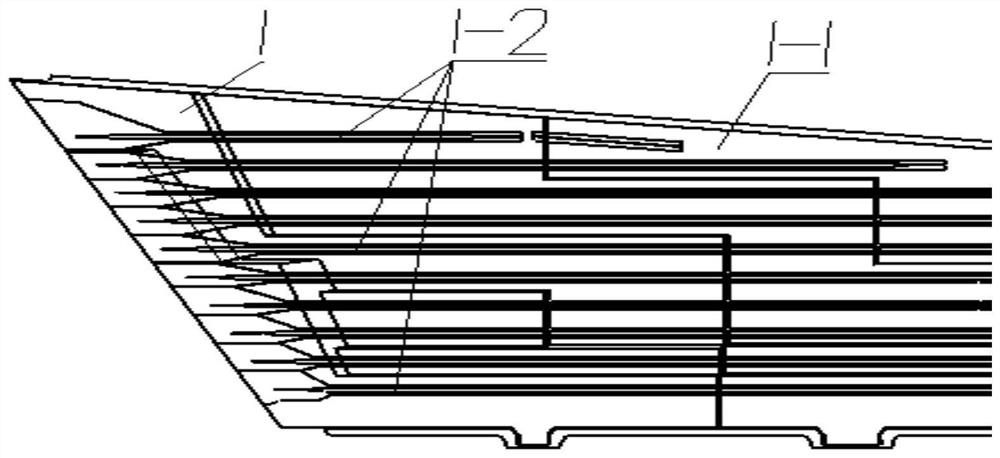

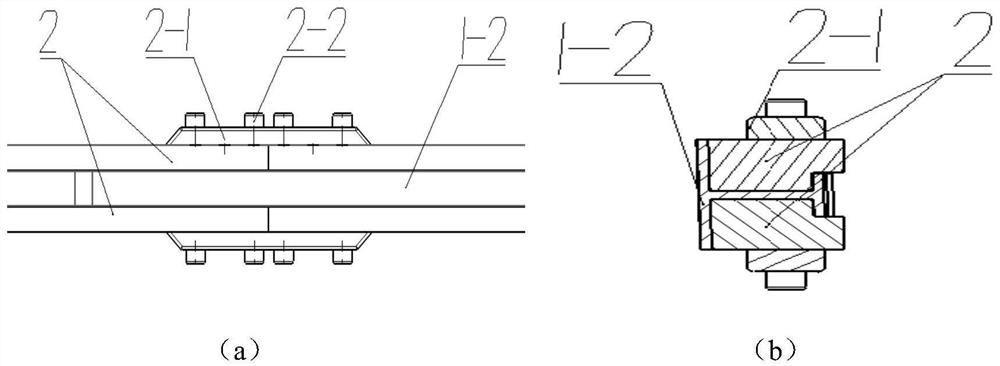

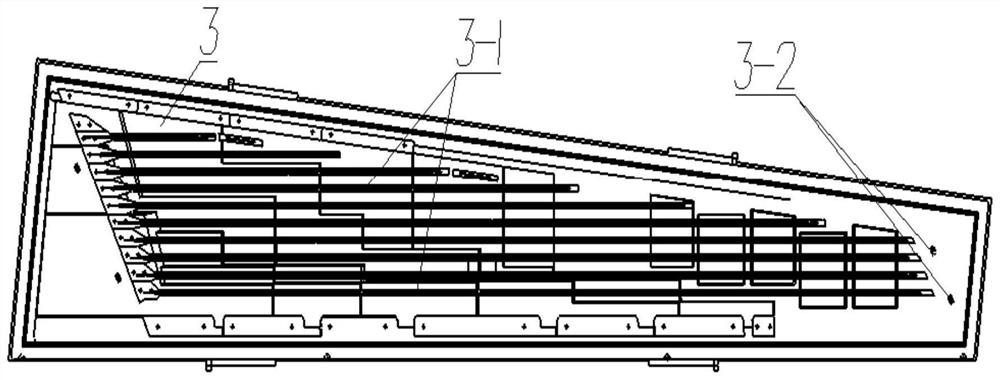

[0020] The present invention uses three sets of relatively independent tooling to complete the molding of the parts. A set of long stringer laying and forming molds 2 are used to lay up the long stringer. Since the length of the long stringer is long, the stringer is divided into segments, each segment is connected by a side plate 2-1. The forming surface of the cover plate molding die and the long stringer pre-compaction die 3 is the outer surface of the wall panel parts, and the soft film molding of composite parts can be directly completed on it. When forming the soft film, the position of the long stringer and its tooling is directly reserved. The forming temperature of the composite soft film is relatively low, so the material of the tooling is ordinary steel. The cover plate molding die and stringer pre-compacting die 3 are also used for pre-compacting the I-shaped stringer. The stacked stringer parts and tooling are placed at the position of the stringer spacer 3-1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com