Laser sintering sand, preparation method thereof, sand core and preparation method thereof

A laser sintering and sand core technology, applied in the direction of cores, manufacturing tools, casting and molding equipment, etc., can solve the problem of low sand core strength, and achieve the effects of reducing manual intervention, high sintering initial strength, and improving molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

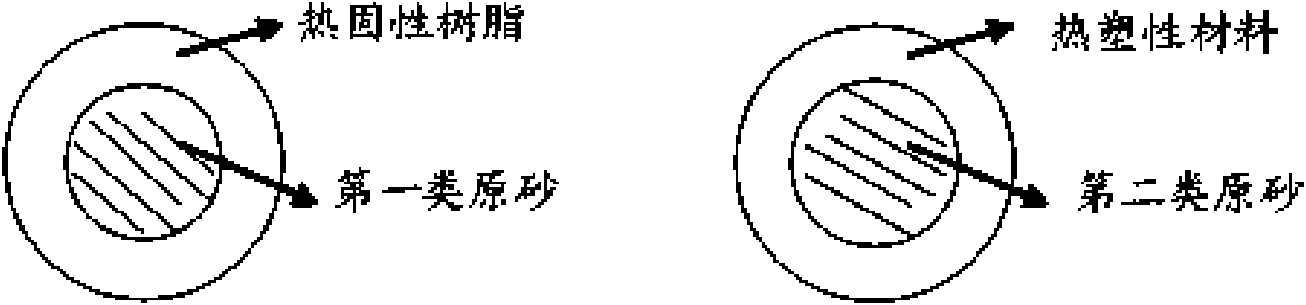

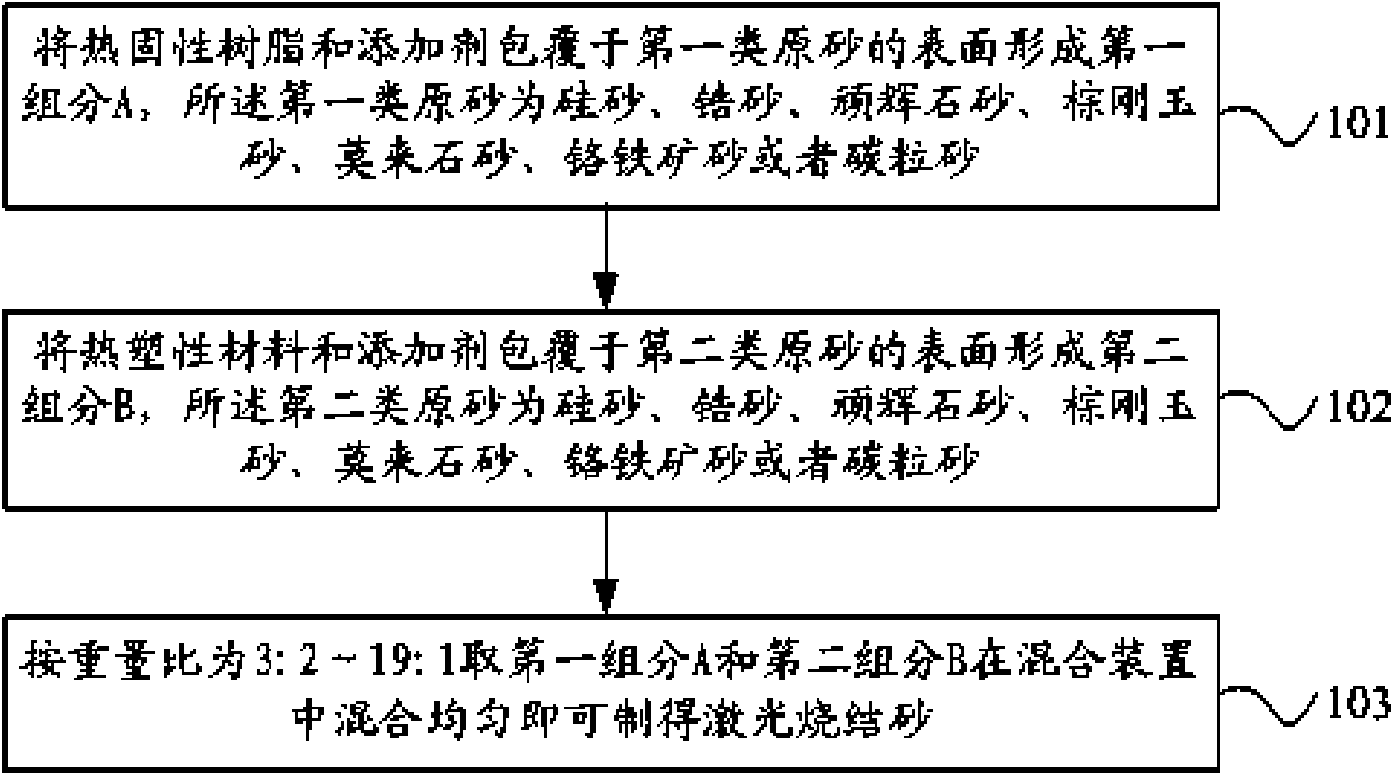

[0044] image 3 It is a schematic flow chart of the preparation method of laser sintered sand of the present invention. Such as image 3 Shown, the preparation method of described laser sintering sand comprises the following steps:

[0045] Step 101, coating thermosetting resin and additives on the surface of the first type of raw sand to form the first component A, the first type of raw sand is silica sand, zircon sand, enstatite sand, corundum sand, limestone sand, magnesium sand sand, mullite sand, chromite sand or carbon grain sand.

[0046] The thermosetting resin and additives in the first component A prepared in step 101 are coated on the surface of the first type of raw sand. Coating the thermosetting resin and additives on the surface of the first type of raw sand is thermal coating. In this embodiment, the thermosetting resin is a thermosetting phenolic resin.

[0047] The additives include a curing agent, a lubricant and a coupling agent. The step 101 includes t...

Embodiment 1

[0068] Preparation of the first component A: First, heat 2,000 parts of scrubbed silica sand with specifications of 70 mesh to 140 mesh, AFS fineness of 50 to 60, and silica sand value of 85 to 180°C, then add it to the rotor sand mixer and stir at high speed ; Secondly, after adding 1 part of r-aminopropyltriethoxysilane, stir for 10 seconds; then, add 40 parts of high-strength low-gas phenolic resin (PF1901, Jinan Shengquan Company) with a softening point of 85 ° C and stir for 60 seconds to 90 seconds; then, add 8 parts of 50% aqueous solution of hexamethylenetetramine and continue stirring for 60 seconds; then, add 2 parts of calcium stearate and continue stirring for 30 seconds to 60 seconds; finally, when the mixture is cooled to the resin After softening point, the mixture is broken up by stirring, sanded and sieved.

[0069] Preparation of the second component B: First, heat 110 parts of montan wax with a melting point of 80°C to 100°C to fully melt, then add 45 parts ...

Embodiment 2

[0074] The preparation of the first component A is the same as in Example 1.

[0075] Preparation of the second component B: First, heat 2000 parts of the same raw sand as in Example 1 to 240°C and add it to the sand mixer; secondly, quickly add 1 part of r-aminopropyltriethoxysilane Coupling agent, stir for about 10 seconds; then, add 120 grams of low-melting point ternary copolymerized nylon powder with a melting point between 90°C and 100°C, and stir for 150 seconds; finally, add 40 parts of the same as in Example 1 at 100°C in advance The fully melted montan wax, polyethylene-ethyl acetate copolymer resin and terpene resin are mixed and melted and stirred for 120 seconds. After the mixture is fully cooled, the mixture is broken up, sanded and sieved.

[0076] The mixing ratio of the first component A and the second component B and the laser sintering process are the same as in the first embodiment.

[0077] The secondary curing process is the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com