Precinct laser fusion rapid molding method and device of medical implantation material wax mould

A technology of selective laser melting and forming method, applied in application, home appliances, other home appliances, etc., can solve the problems of difficult diagnosis and repair, lack of topology information, point diffusion, etc., to achieve compact and lightweight equipment design, compact system structure, The effect of reducing the weight of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

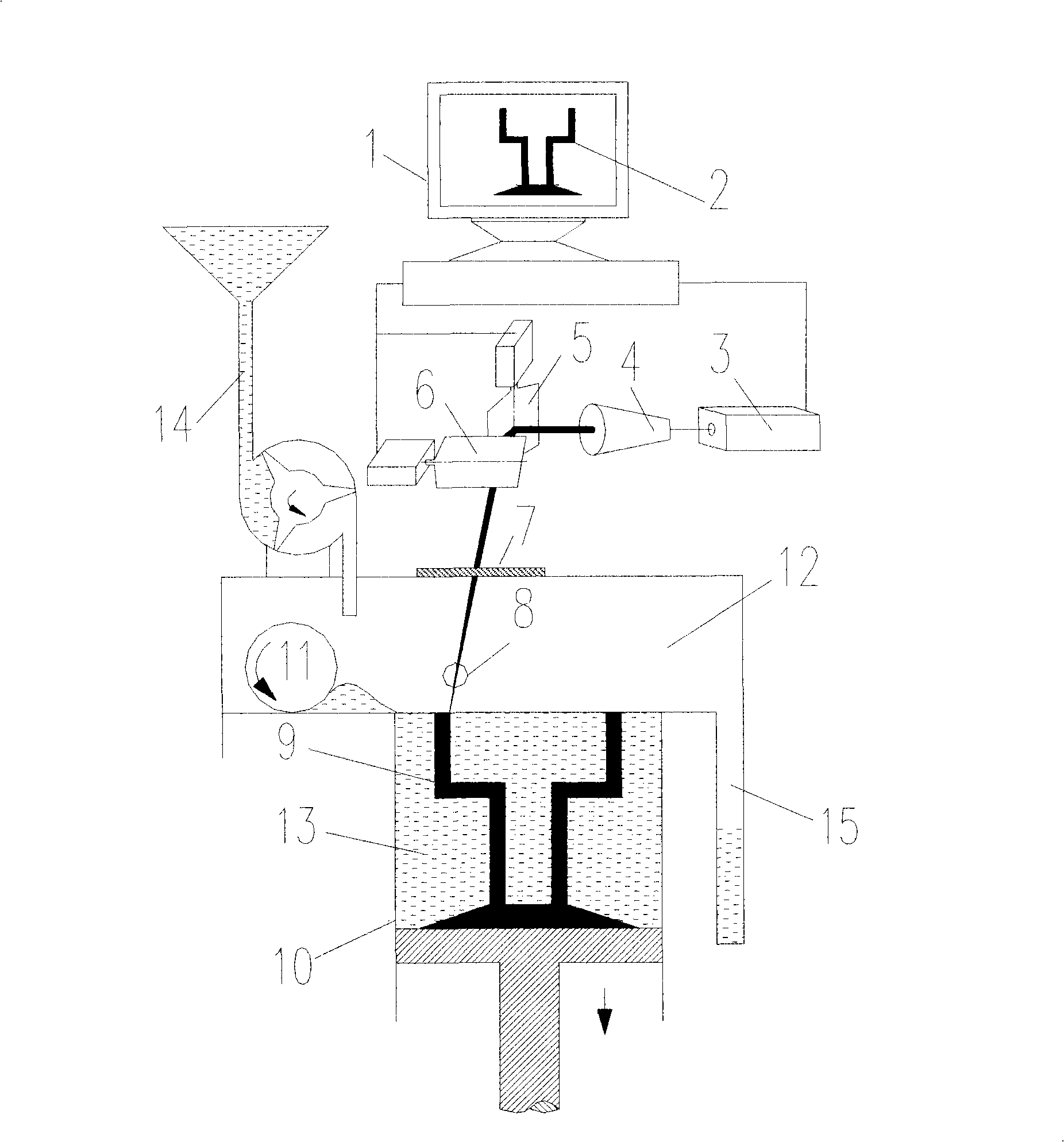

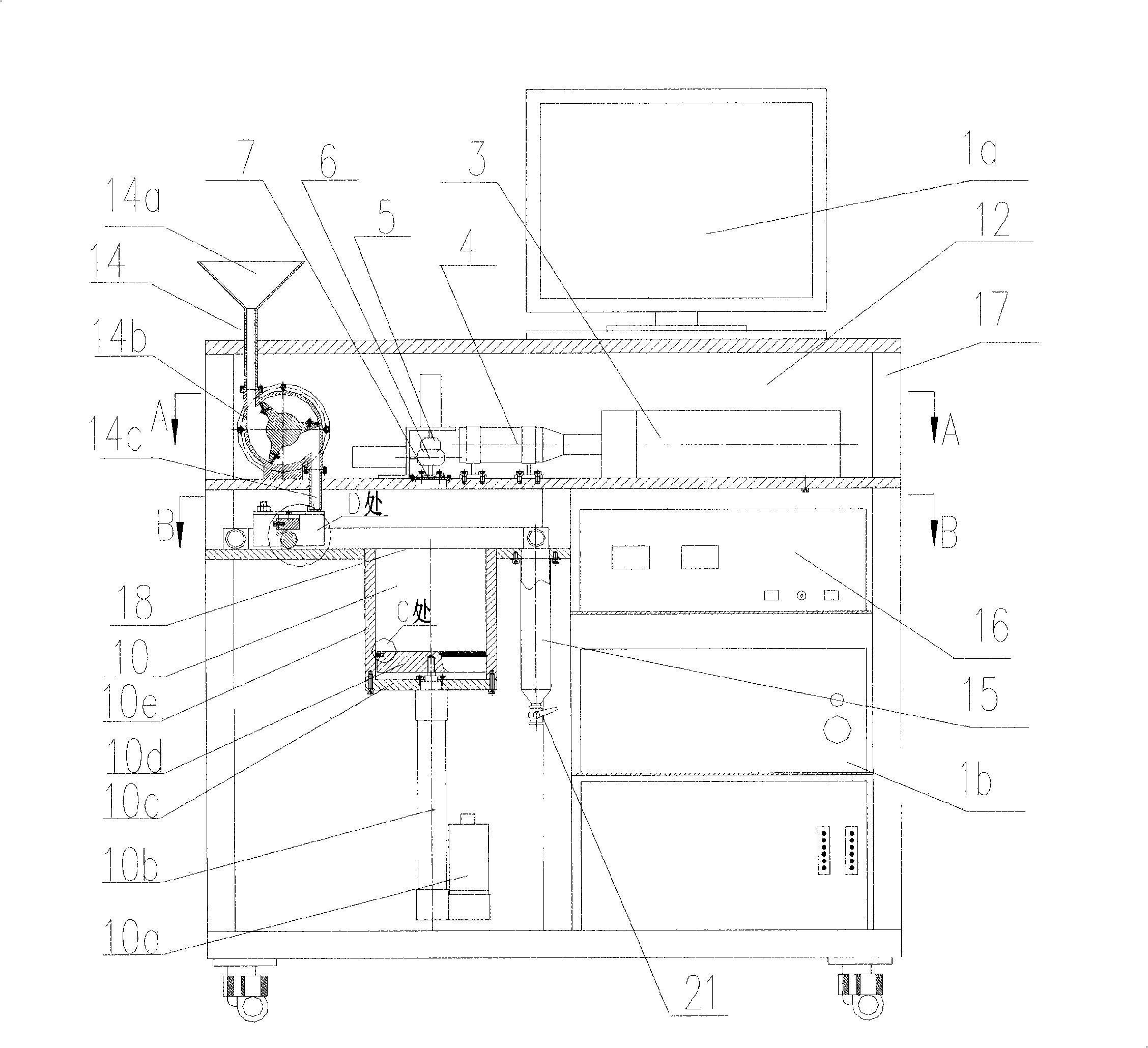

[0048] like figure 1 As shown, the device for the selective laser melting rapid prototyping method of the medical implant wax model includes a host computer 1, a laser focusing and scanning system, and a powder laying system. The laser focusing and scanning system adopts the method of scanning first and then focusing. It includes a laser 3, a beam expander 4, an X-axis scanning galvanometer 5, a Y-axis scanning galvanometer 6, and a focusing lens 7 sequentially connected by an optical path; the laser 3 adopts a radio frequency CO2 laser of TEM00 mode, the output power is ≤10W, and the wavelength is 10.6 μm, beam quality factor M2 ≤ 1.2, laser output spot ≤ 4mm; beam expander 4 with a beam expansion factor of 5 to 8 times; X-axis scanning galvanometer 5, Y-axis scanning galvanomet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com