Three-drum forming machine for producing green tyre and method thereof

A three-drum molding machine and tire technology, applied in the field of rubber machinery, can solve the problems of tire uniformity and efficiency that the molding quality is difficult to control, long and complicated production process, long manufacturing time, etc., so as to improve tire uniformity and molding. Efficiency, shortened production time, simplified production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

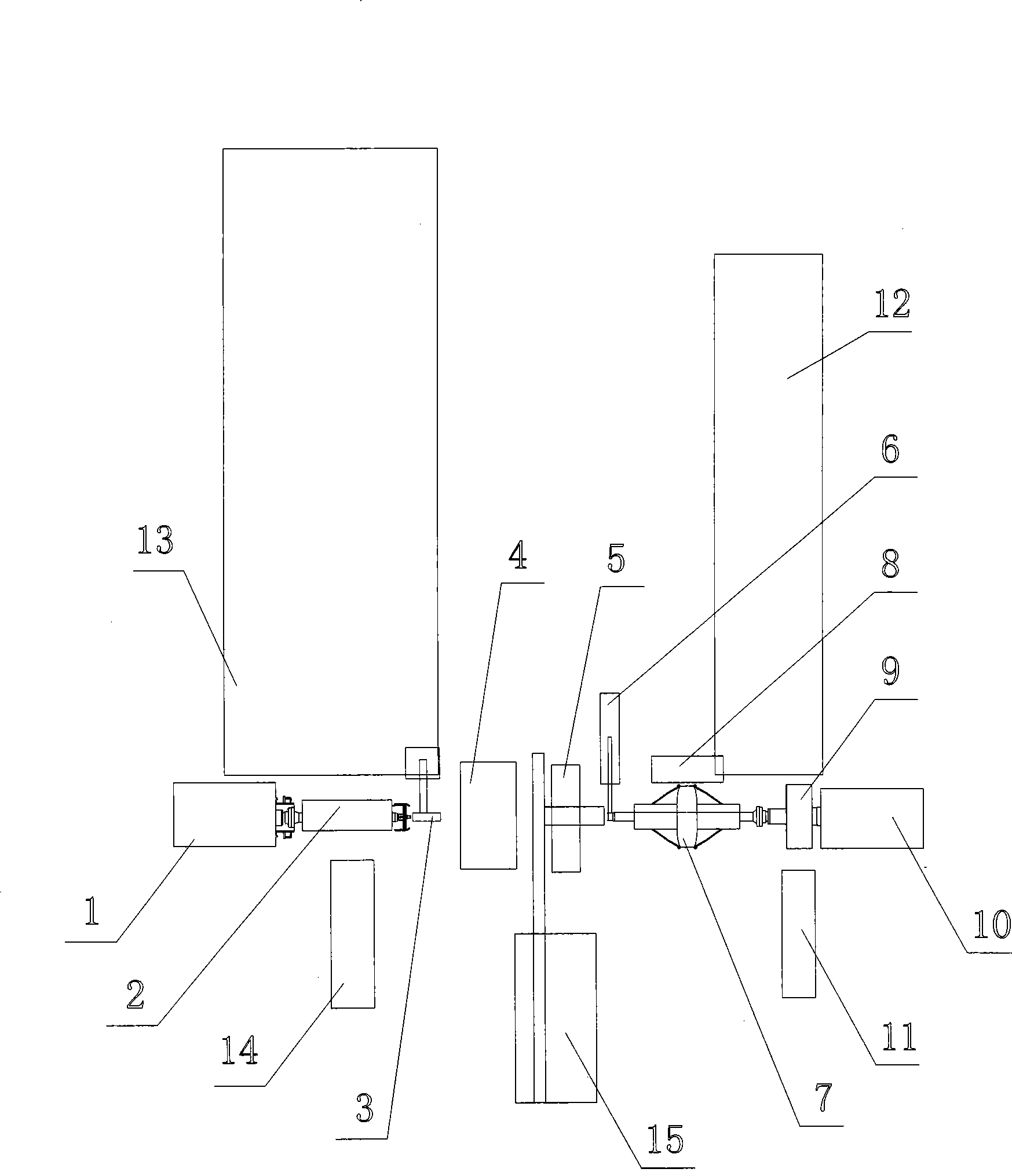

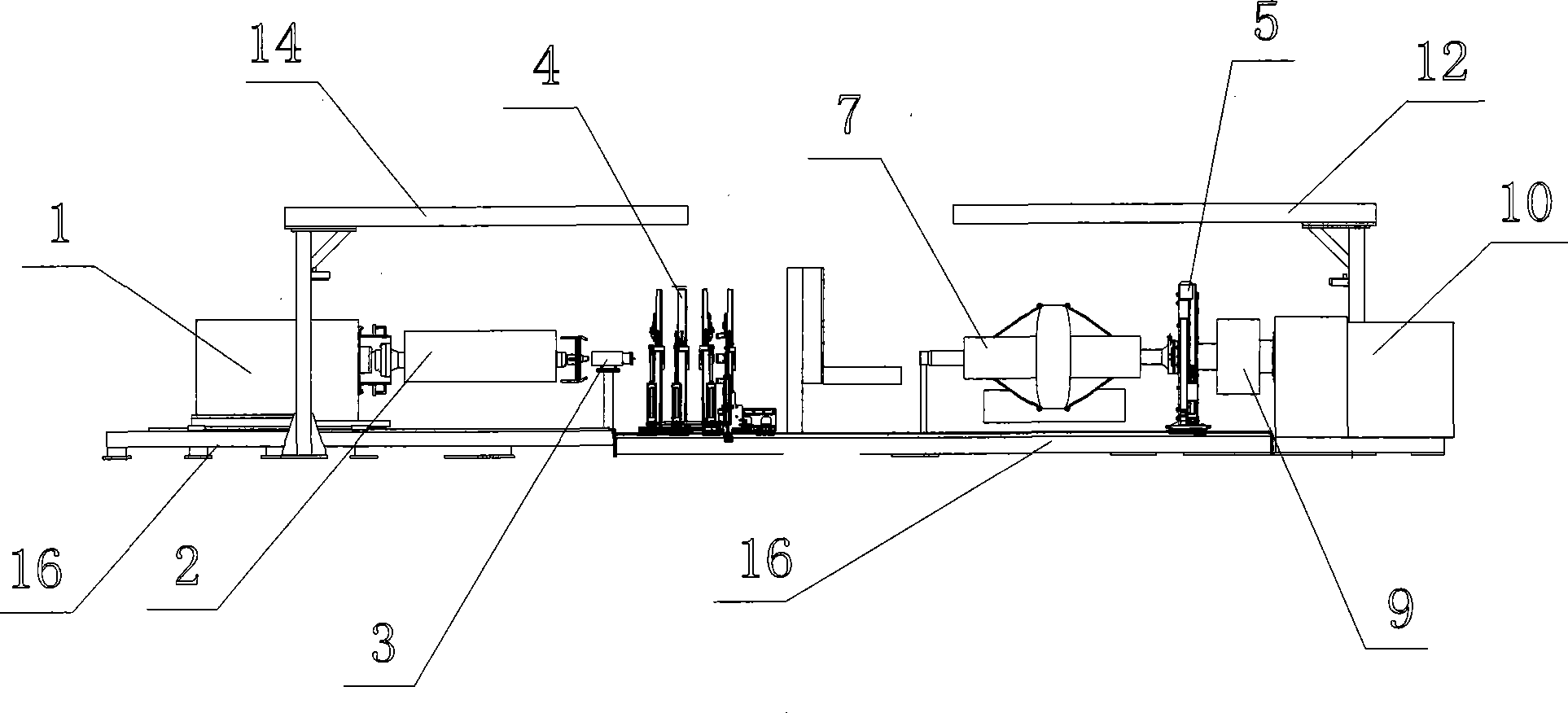

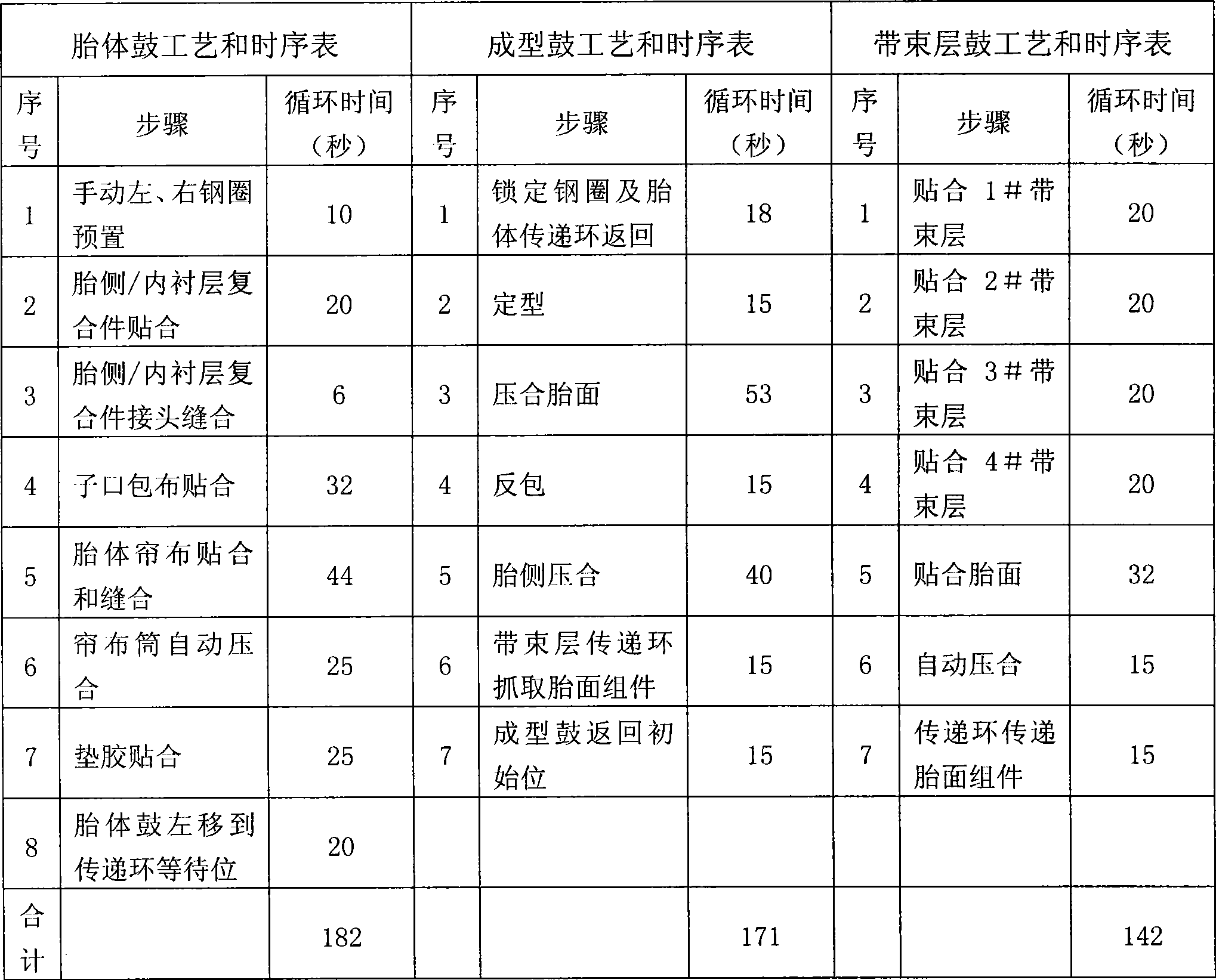

[0050] Example 1, such as figure 1 and figure 2 As shown, the three-drum building machine for manufacturing tire blanks includes a carcass drum 2, a belt layer drum 9 and a forming drum 7, and the three drums are arranged on the same horizontal axis.

[0051] The feeding system of the carcass drum 2 includes a carcass feeding rack 13 and a pad rubber feeding rack 14 arranged on both sides of the carcass drum 2 .

[0052] The feeding system of the belt drum 9 includes a tread feeder 11 and a belt feeder 12 arranged on both sides of the belt drum 9 .

[0053] The driving unit of the carcass drum 2 is the carcass drum transmission box 1 coaxially arranged outside the carcass drum 2 .

[0054] The forming drum 7 and the belt drum 9 are carried by the same forming drum drive unit, that is, the forming drum drive box 10 coaxially arranged on the outside of the belt drum 9 .

[0055] The carcass drum transmission box 1 and the forming drum drive box 10 are relatively and coaxiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com