Ceramic material for 3D (three-dimensional) light curing forming printing and preparation method thereof

A technology of photocuring molding and ceramic materials, applied in the field of 3D printing, can solve the problems of lack of high precision, shape ceramic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

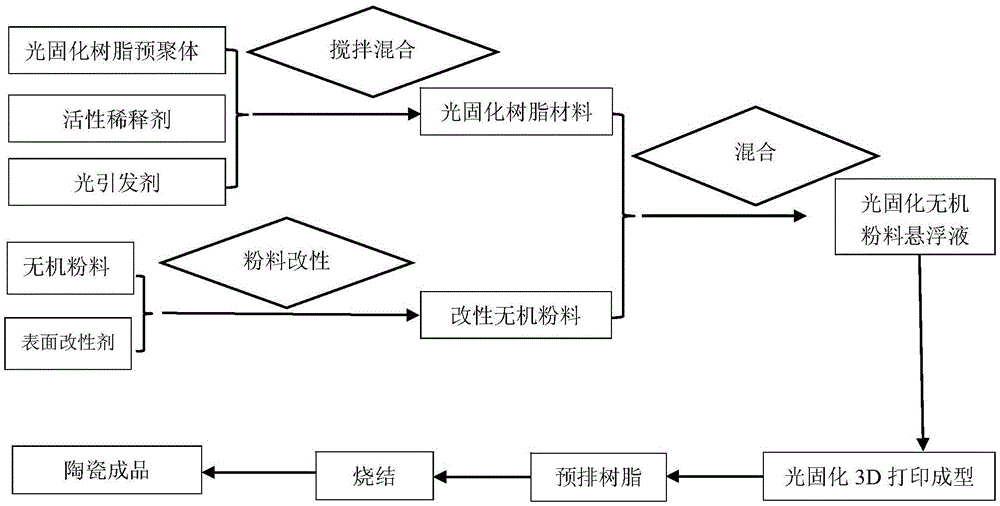

Method used

Image

Examples

Embodiment 1

[0143] Take the photoinitiator and reactive diluent into a three-necked flask, and stir and mix at 30°C for 20min. Then add photocurable resin prepolymer, stir and mix at 30° C. for 30 minutes to obtain photocurable resin. The weight ratio of photocurable resin prepolymer, reactive diluent and photoinitiator is 85:10:5. Wherein, the photocurable resin prepolymer is selected from two mixtures of acrylic resin and epoxy resin, and the weight ratio of acrylic resin and epoxy resin is 70:20. The acrylic resin is bisphenol A diglycidyl ether diepoxy acrylic resin and polyurethane acrylate. The epoxy resin is bisphenol A diglycidyl ether diepoxy resin and glycidyl ester epoxy resin. The reactive diluent is an acrylate monomer, and the acrylate monomer is ethoxylated trimethylol acrylate. The photoinitiator is selected from the mixture of cationic photoinitiator and free radical photoinitiator, and the weight ratio of cationic photoinitiator and free radical photoinitiator is 1:2....

Embodiment 2

[0147] Take the photoinitiator and reactive diluent into a three-necked flask, and stir and mix at 40°C for 30min. Then add photocurable resin prepolymer, stir and mix at 40° C. for 30 minutes to obtain photocurable resin. The weight ratio of photocurable resin prepolymer, reactive diluent and photoinitiator is 100:30:10. Wherein, the photocurable resin prepolymer is selected from two mixtures of acrylic resin and epoxy resin, and the weight ratio of acrylic resin and epoxy resin is 80:20. The acrylic resin is bisphenol A diglycidyl ether diepoxy acrylic resin. The epoxy resin is bisphenol A diglycidyl ether diepoxy resin. The active diluent is an acrylate monomer, and the acrylate monomer is tricyclodecanyl dimethanol diacrylate. The photoinitiator is selected from the mixture of cationic photoinitiator and free radical photoinitiator, and the weight ratio of cationic photoinitiator and free radical photoinitiator is 1:4. The cationic photoinitiator is bis-2,6-difluoro-3-...

Embodiment 3

[0151] Take the photoinitiator and put it into a three-necked flask, and stir and mix at 40°C for 20min. Then add photocurable resin prepolymer, stir and mix at 40° C. for 20 minutes to obtain photocurable resin. The weight ratio of photocurable resin prepolymer and photoinitiator is 25:2. Wherein, the photocurable resin prepolymer is selected from two mixtures of acrylic resin and epoxy resin, and the weight ratio of acrylic resin and epoxy resin is 80:5. The acrylic resin is urethane acrylate. The epoxy resin is a dicyclopentadiene phenol type epoxy resin. The photoinitiator is selected from the mixture of cationic photoinitiator and free radical photoinitiator, and the weight ratio of cationic photoinitiator and free radical photoinitiator is 1:5. The cationic photoinitiator is 4-isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate. The free radical photoinitiator is 1-hydroxycyclohexyl phenyl ketone.

[0152] The surface modifier is used to modify the inorganic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com