Pealite like thermal treating steel rail and producing method thereof

A production method and pearlite technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as difficult operation, fatigue cracking, and high carbon equivalent, and achieve broad application prospects, good wear resistance, and excellent weldability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The weight percentage of the chemical composition of the rail steel is: C: 0.76%, Si: 0.61%, Mn: 0.81%, V: 0.06%, Cr: 0.68%, P: 0.014%, S: 0.012%, the rest is iron, others Trace elements and impurities, of which Mn+2Cr+5Mo+3Nb=2.17%.

[0035] After the rail is rolled, the temperature of the residual heat is 840°C, and the rail head is spray-cooled at a cooling rate of 4.0°C / s for 110 seconds. When the temperature is 450°C, the cooling is stopped, and it is left naturally. After heat treatment, a fine pearlite structure is obtained. The mechanical properties are: tensile strength Rm is 1360MPa, yield strength Rp0.2 is 940MPa, elongation A is 13%, Brinell hardness of rail head tread is 390HB, Rockwell hardness of rail head section 3mm from the surface is 41.5HRC, The Rockwell hardness at 21mm on the surface is 39.0HRC, and the depth of the hardened layer is 39mm.

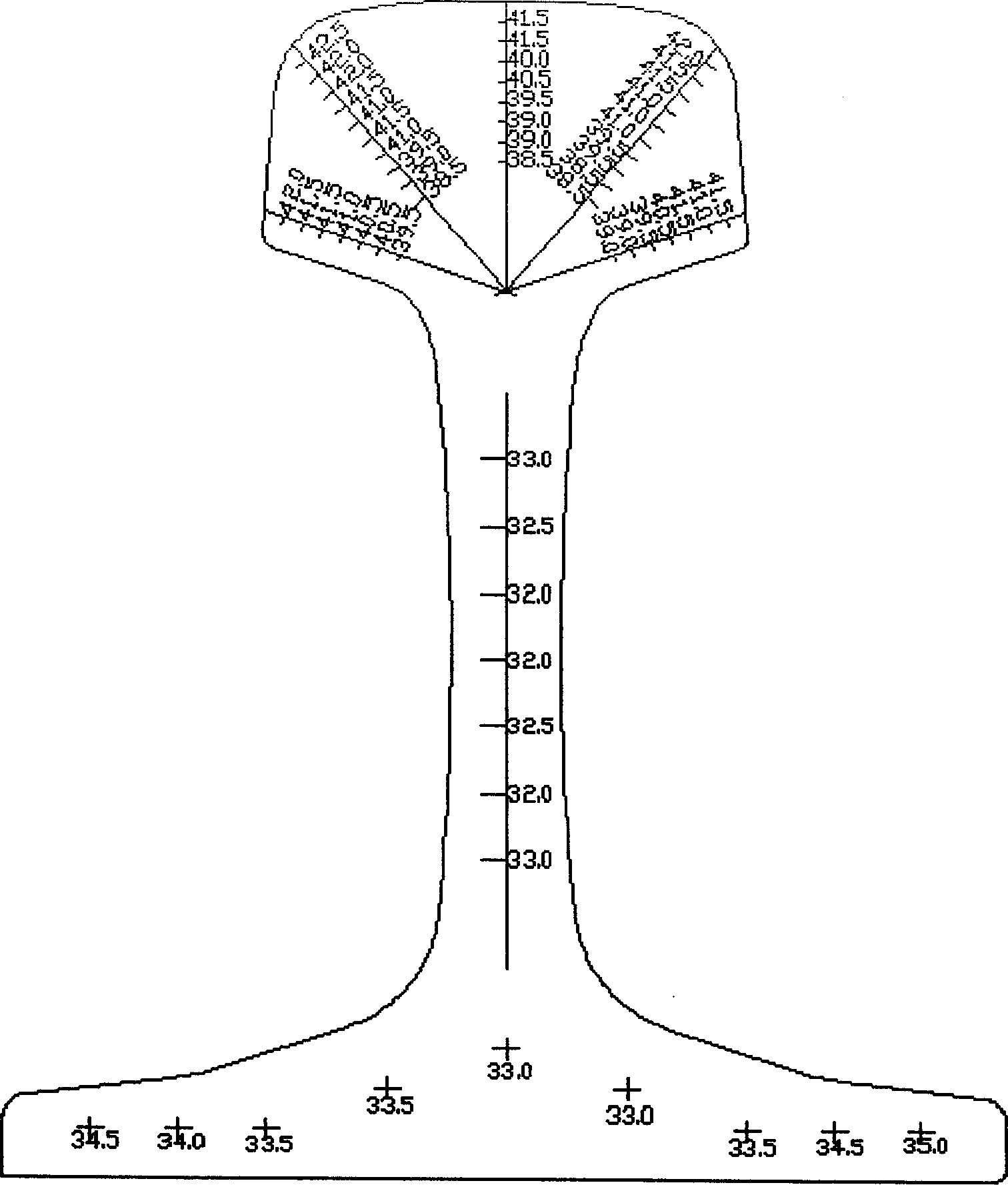

[0036] figure 1 It is a schematic diagram of the obtained steel rail's full-section hardness. In the figure, t...

Embodiment 2

[0050] The weight percentage of the chemical composition of the rail steel is: C: 0.70%, Si: 0.55%, Mn: 0.96%, V: 0.08%, Cr: 0.46%, P: 0.022%, S: 0.011%, Ti: 0.01%, The rest is iron, other trace elements and impurities, of which Mn+2Cr+5Mo+3Nb=1.88%

[0051] After the rail is rolled, the temperature of the residual heat is 785°C, and the rail head is spray-cooled at a cold rate of 5.0°C / s for 70 seconds. When the temperature is 438°C, the cooling stops and it is left naturally. After heat treatment, a fine pearlite structure is obtained. The mechanical properties are: tensile strength Rm is 1330MPa, yield strength Rp0.2 is 905MPa, elongation A is 12%, Brinell hardness of rail head tread is 380HB, Rockwell hardness of rail head section 3mm from the surface is 39.5HRC, The Rockwell hardness at 21mm on the surface is 38.5HRC, and the depth of the hardened layer is 35mm.

[0052] After the wear test, the wear rate is 29% of the U71Mn hot-rolled rail, that is, the wear resistance is 3....

Embodiment 3

[0054] The weight percentage of the chemical composition of rail steel is: C: 0.85%, Si: 0.73%, Mn: 0.75%, V: 0.11%, Cr: 0.38%, P: 0.019%, S: 0.010%, Nb: 0.03%, Cu: 0.30%. The rest is iron, other trace elements and impurities, of which Mn+2Cr+5Mo+3Nb=1.60%.

[0055] After the rail is rolled, the temperature of the residual heat is 682°C, and the rail head is cooled with compressed air at a cooling rate of 2.5°C / s for 100 seconds. When the temperature is 437°C, the cooling stops and it is left naturally. After heat treatment, a fine pearlite structure is obtained. The mechanical properties are: tensile strength Rm is 1390MPa, yield strength Rp0.2 is 1040MPa, elongation A is 11%, rail head tread Brinell hardness is 401HB, rail head section 3mm from the surface, Rockwell hardness is 41.5HRC, The Rockwell hardness at 21mm on the surface is 40.0HRC, and the depth of the hardened layer is 35mm. According to the neutral salt spray accelerated corrosion comparison test, the corrosion rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com