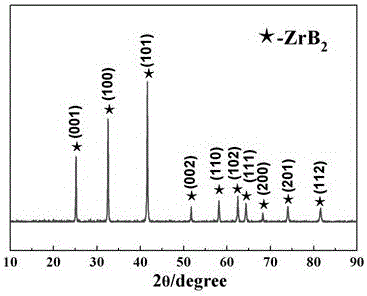

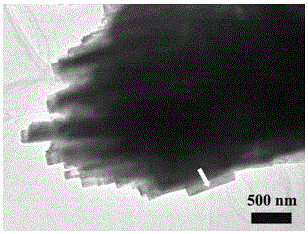

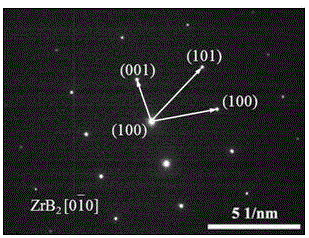

Nano rodlike zirconium boride powder and preparation method thereof

A nano-rod-shaped zirconium boride technology, applied in the field of zirconium boride powder, can solve the problems of high raw material cost of zirconium boride powder, lack of uniform rod-shaped structure, and difficulty in industrial production, and achieve considerable industrialization prospects. Effect of enhancing sintering activity and lowering synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A nanorod-shaped zirconium boride powder and a preparation method thereof. Described preparation method is:

[0038] (1) 36-39wt% zirconia powder, 14-16wt% boron carbide powder, 4-8wt% amorphous carbon powder, 12-16wt% sodium chloride powder and 24-30wt% The potassium chloride powder is mixed uniformly to obtain a mixture.

[0039] (2) Put the mixture into a crucible, put the crucible into a sagger, and then fill the gap between the sagger and the crucible with silicon carbide powder.

[0040] (3) Place the sagger after filling the gap in a microwave heating furnace, and raise the temperature to 1000-1150°C at a heating rate of 10-20°C / min under a vacuum degree of 10-50Pa and a flowing argon atmosphere, Keep warm for 20-25 minutes, and cool naturally to obtain rough zirconium boride powder.

[0041] (4) Wash the coarsely treated zirconium boride powder with deionized water for 3 to 5 times, and keep it in a vacuum oven at 65 to 80°C for 6 to 12 hours to obtain nanoro...

Embodiment 2

[0044] A nanorod-shaped zirconium boride powder and a preparation method thereof. Described preparation method is:

[0045](1) 32-37wt% zirconia powder, 11-15wt% boron carbide powder, 6-7wt% amorphous carbon powder, 14-18wt% sodium chloride powder and 27-33wt% The potassium chloride powder is mixed uniformly to obtain a mixture.

[0046] (2) Put the mixture into a crucible, put the crucible into a sagger, and then fill the gap between the sagger and the crucible with silicon carbide powder.

[0047] (3) Place the sagger after filling the gap in a microwave heating furnace, and raise the temperature to 1000-1200°C at a heating rate of 10-30°C / min under a vacuum degree of 10-50Pa and a flowing argon atmosphere, Insulate for 20-30 minutes, and cool naturally to obtain rough-treated zirconium boride powder.

[0048] (4) Wash the coarsely treated zirconium boride powder with deionized water for 3 to 5 times, and keep it in a vacuum oven at 65 to 80°C for 6 to 12 hours to obtain ...

Embodiment 3

[0051] A nanorod-shaped zirconium boride powder and a preparation method thereof. Described preparation method is:

[0052] (1) 27-31wt% zirconia powder, 9-12wt% boron carbide powder, 5-6wt% amorphous carbon powder, 17-20wt% sodium chloride powder and 31-36wt% The potassium chloride powder is mixed uniformly to obtain a mixture.

[0053] (2) Put the mixture into a crucible, put the crucible into a sagger, and then fill the gap between the sagger and the crucible with silicon carbide powder.

[0054] (3) Place the sagger after filling the gap in a microwave heating furnace, and raise the temperature to 1150-1200°C at a heating rate of 20-40°C / min under a vacuum degree of 10-50Pa and a flowing argon atmosphere, Keep warm for 25-40 minutes, and cool naturally to get rough zirconium boride powder.

[0055] (4) Wash the coarsely treated zirconium boride powder with deionized water for 3 to 5 times, and keep it in a vacuum oven at 65 to 80°C for 6 to 12 hours to obtain nanorod zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com