Special sagger for sintering lithium battery positive electrode material and preparation method of sagger

A positive electrode material and lithium battery technology, applied in the field of refractory materials, can solve the problems of less use of saggers and high cost of saggers, achieve high economic value and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

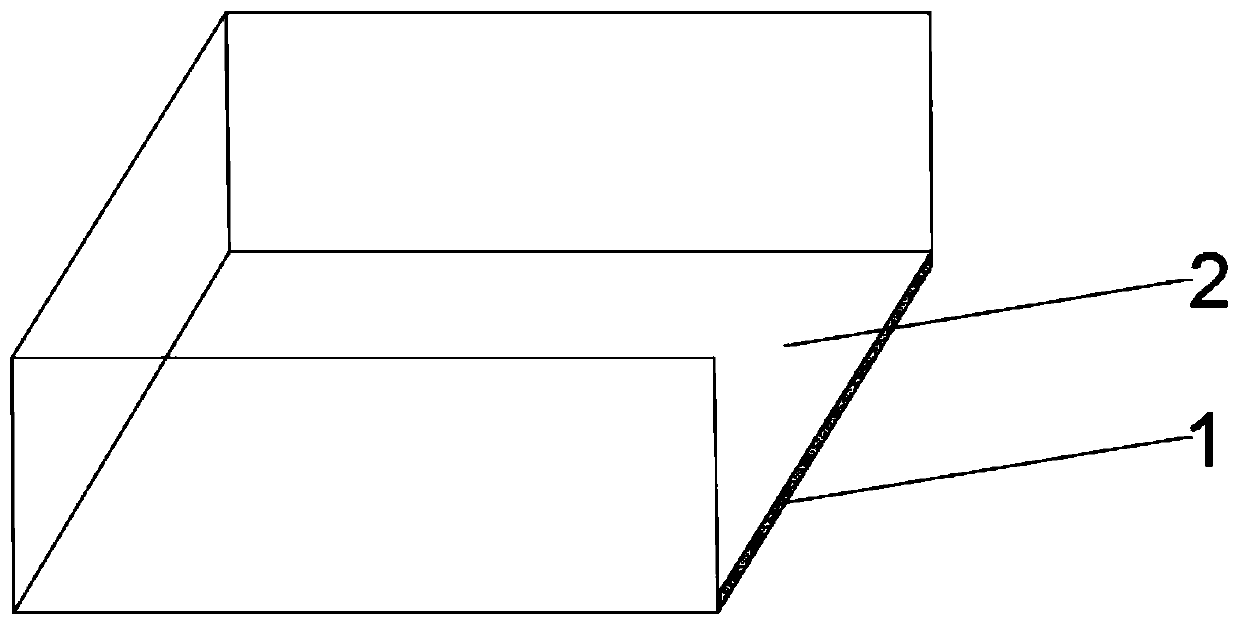

[0024] The special sagger for sintering lithium battery cathode materials includes a sagger main body and a corrosion-resistant layer integrally pressed and formed with the sagger main body at the bottom of the sagger main body; the corrosion-resistant layer includes the following raw materials: 1.5mm aluminum-magnesium tip 22% of spar, 20% of 0.5mm fused corundum, 16% of 325 mesh zirconia powder, 11% of 325 mesh kaolin powder, 20% of 5μ alumina powder, 5% of binder, and 6% of water; the main body of the sagger Including the following raw materials: 1.0mm cordierite 28%, 1.3mm sintered mullite 31%, 5μ alumina powder 15%, 325 mesh kaolin powder 15%, binder 5%, water 6%.

[0025] The above-mentioned preparation method for sagger special for sintering lithium battery cathode material comprises the following steps:

[0026] S1: Weigh the raw materials of corrosion-resistant layer, aluminum-magnesium spinel, fused corundum, zirconia powder, kaolin powder, alumina powder, and binder...

Embodiment 2

[0031] The special sagger for sintering lithium battery cathode materials includes a sagger main body and a bottom layer of the sagger main body provided with a corrosion-resistant layer integrally pressed and formed with the sagger main body; the corrosion-resistant layer includes the following raw materials: 0.1mm aluminum-magnesium tip 20% of spar, 15% of 1.0mm fused corundum, 18% of 325 mesh zirconia powder, 15% of 325 mesh kaolin powder, 23% of 5μ alumina powder, 2% of binder, and 7% of water; the main body of the sagger Including the following raw materials: 0.5mm cordierite 25%, 0.1mm sintered mullite 38%, 5μ alumina powder 10%, 325 mesh kaolin powder 18%, binder 2%, water 7%.

[0032] The above-mentioned preparation method for sagger special for sintering lithium battery cathode material comprises the following steps:

[0033] S1: Weigh the raw materials of corrosion-resistant layer, aluminum-magnesium spinel, fused corundum, zirconia powder, kaolin powder, alumina pow...

Embodiment 3

[0038] The special sagger for sintering lithium battery cathode materials includes a sagger main body and a corrosion-resistant layer integrally pressed and formed with the sagger main body at the bottom of the sagger main body; the corrosion-resistant layer includes the following raw materials: 0.5mm aluminum-magnesium tip 28% of spar, 19% of 0.1mm fused corundum, 10% of 325 mesh zirconia powder, 10% of 325 mesh kaolin powder, 25% of 5μ alumina powder, 3% of binder, and 5% of water; the main body of the sagger Including the following raw materials: 0.8mm cordierite 34%, 0.8mm sintered mullite 27%, 5μ alumina powder 12%, 325 mesh kaolin powder 19%, binder 3%, water 5%.

[0039] The above-mentioned preparation method for sagger special for sintering lithium battery cathode material comprises the following steps:

[0040] S1: Weigh the raw materials of corrosion-resistant layer, aluminum-magnesium spinel, fused corundum, zirconia powder, kaolin powder, alumina powder, and binder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com