Alumina base andalusite-SiC-C brick, manufacturing method and its application

A production method, andalusite technology, applied in the field of refractory materials, can solve problems such as abnormal structural peeling of ASC bricks, hidden dangers of safe operation, and melting loss in the impact zone, so as to improve the load conversion point, reduce melting loss, and enhance high temperature wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

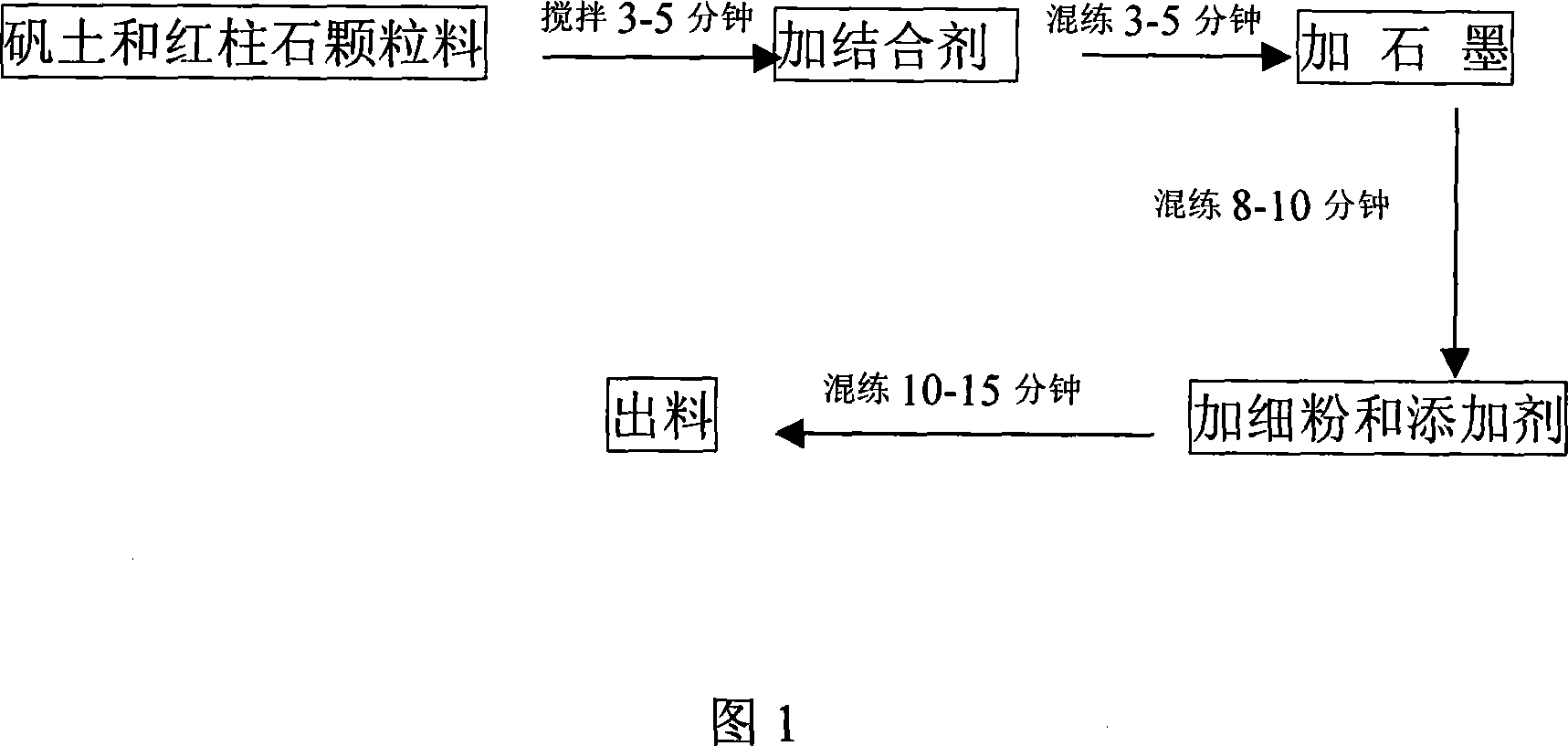

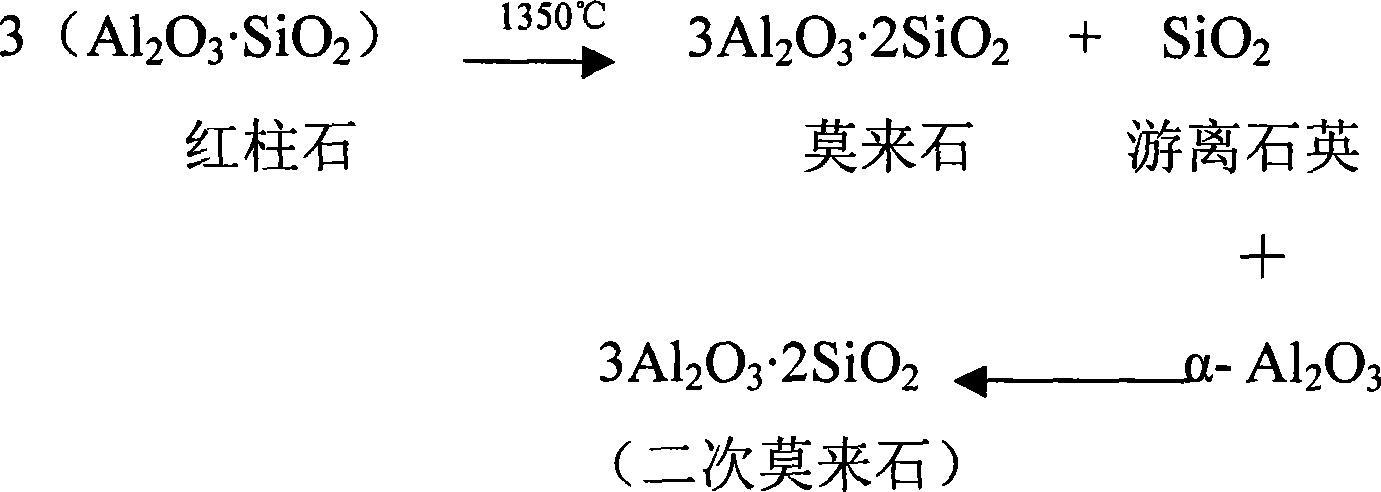

Method used

Image

Examples

Embodiment 1

[0045] Provide alumina-based andalusite-SiC-C bricks containing Al 2 o 3 The mass percent is 51.6, SiC is 12.8, and C is 10.6. The specific ratio is 8-5mm bauxite 12%, 5-3mm bauxite 20%, 3-1mm andalusite 20%, ≤1mm andalusite 15%, ≤1mm silicon carbide 7%, ≤45μm silicon carbide 7%, ≤ 0.15mm flake graphite 10%, ≤75μm fused corundum 6%, α-alumina micropowder 1.4%, metal aluminum powder 0.8%, metal silicon powder 0.8%, phenolic resin binder 3.8%. After weighing according to the formula, it is produced according to the production process and is ready for use. Its indicators are shown in Table 3.

Embodiment 2

[0047] Provide alumina-based andalusite-SiC-C bricks containing Al 2 o 3 The mass percent is 56.7, SiC is 9.5, and C is 8.1. The specific ratio is 8-5mm bauxite 15%, 5-3mm bauxite 18%, 3-1mm andalusite 13%, ≤1mm andalusite 23%, ≤1mm silicon carbide 5%, ≤45μm silicon carbide 5%, ≤ 0.15mm flake graphite 7%, ≤75μm fused corundum 8%, α-alumina micropowder 4%, metal aluminum powder 1.0%, metal silicon powder 1.0%, phenolic resin binder 4.5%. After weighing according to the formula, it is produced according to the production process and is ready for use. Its indicators are detailed in Table 3.

[0048] After testing, the product provided by the present invention is compared with the original product index as shown in table 3:

[0049] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com