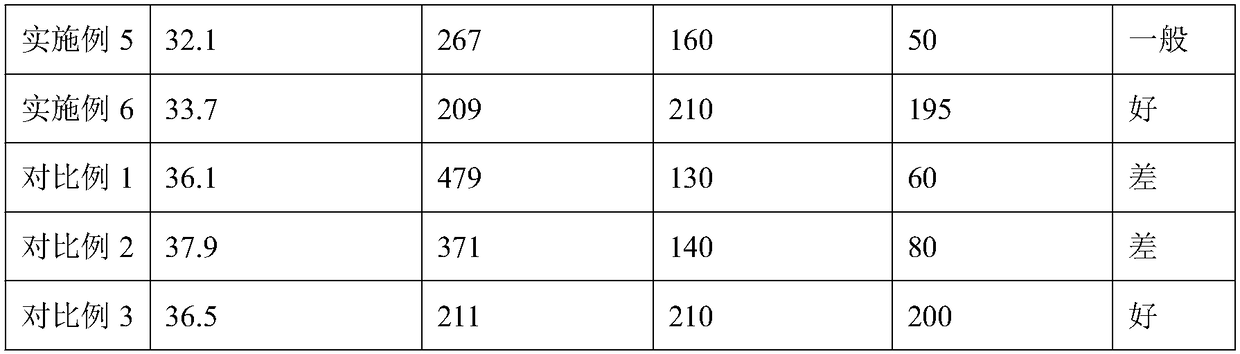

Patents

Literature

41results about How to "Play a role in reducing water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

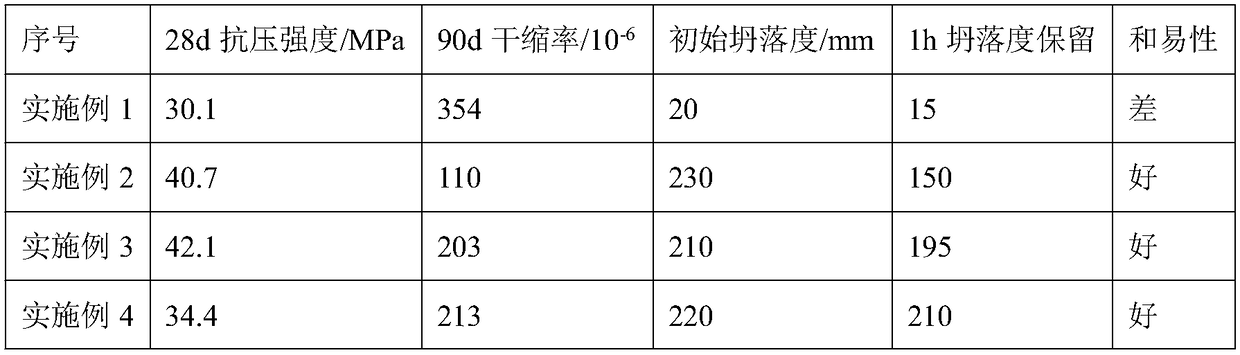

Cement-based self-leveling dry powder mortar for high-cracking-resistance ground

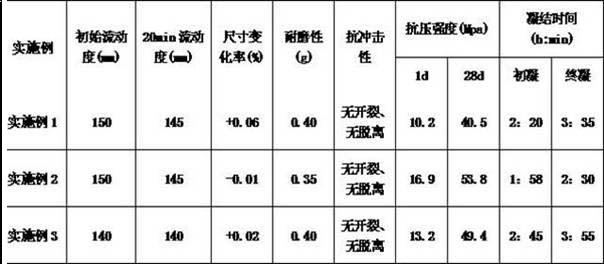

The invention belongs to the technical field of building materials, and particularly relates to cement-based self-leveling dry powder mortar for the ground. The cement-based self-leveling dry powder mortar for the high-cracking-resistance ground consists of cement, fine sand, heavy calcium powder, lithium slag powder, an expanding agent, a solidification adjusting agent, a super plasticizer, a defoaming agent and cracking-resistant fiber. The cement-based self-leveling dry powder mortar for the high-cracking-resistance ground has the characteristics of low cost, high flowing property, bleeding resistance and adjustable setting time during construction as well as high intensity, high cracking resistance, high wearing resistance and flat surface after being hardened. The dry powder mortar has high performance and low cost, and can be widely applied to the fields of ground engineering such as factories, warehouses, shopping plazas, parking lot terrace and the like.

Owner:XINJIANG URBAN CONSTR GRP CO LTD

Recycled concrete and preparation method thereof

The invention discloses recycled concrete, which is characterized by being prepared from the following raw materials in parts by weight: 150-180 parts of cement, 250-300 parts of modified recycled aggregate, 400-450 parts of fine river sand, 5-10 parts of attapulgite, 1-3 parts of porous beta-cyclodextrin cross-linked polymer nanofibers, 50-65 parts of blast furnace slag, 1-3 parts of mullite fibers, 2-5 parts of diazoalkyl urea, 4-8 parts of sulfonate-terminated hyperbranched waterborne polyurethane emulsion, 2-4 parts of additives and 75-90 parts of water. The recycled concrete is prepared from the following raw materials in parts by weight: 2-4 parts of carboxyl-terminated liquid fluororubber and 1-3 parts of water-soluble hyperbranched epoxy resin. The invention also discloses a preparation method of the recycled concrete. The recycled concrete disclosed by the invention is excellent in comprehensive performance, high in strength, low in water absorption rate, good in durability and workability and good in workability.

Owner:曹均云

Superhigh temperature anti-skinning castable

The invention discloses a superhigh temperature anti-skinning castable. The castable comprises the following raw materials in parts by weight: 25-40 parts of corundum or alumina whose particle size is 5-1mm, 10-20 parts of silicon carbide whose particle size is 5-1mm, 5-15 parts of corundum or alumina whose particle size is 1-0.088mm, 10-26 parts of corundum whose particle size is less than 0.088mm, 2-8 parts of aluminum oxide micro powder, 2-6 parts of silica fume, 1-6 parts of aluminate cement, 0.1-0.3 parts of a decondensation agent, 0.005-0.05 parts of a retarder, 1-6 parts of silica sol, and 1-6 parts of water. The superhigh temperature anti-skinning castable has the advantages of good shaping performance and solidification performance, and after solidification, the castable has good high temperature resistance, erosion resistance, and thermal shock resistance.

Owner:ANHUI RUITAI NEW MATERIALS TECH

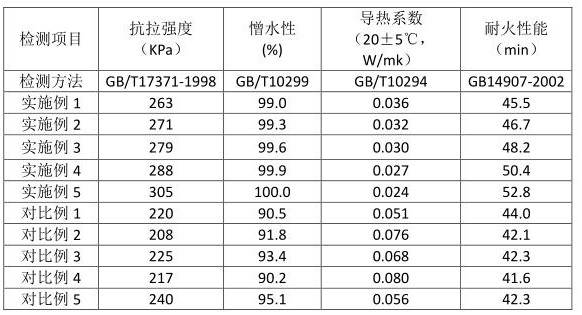

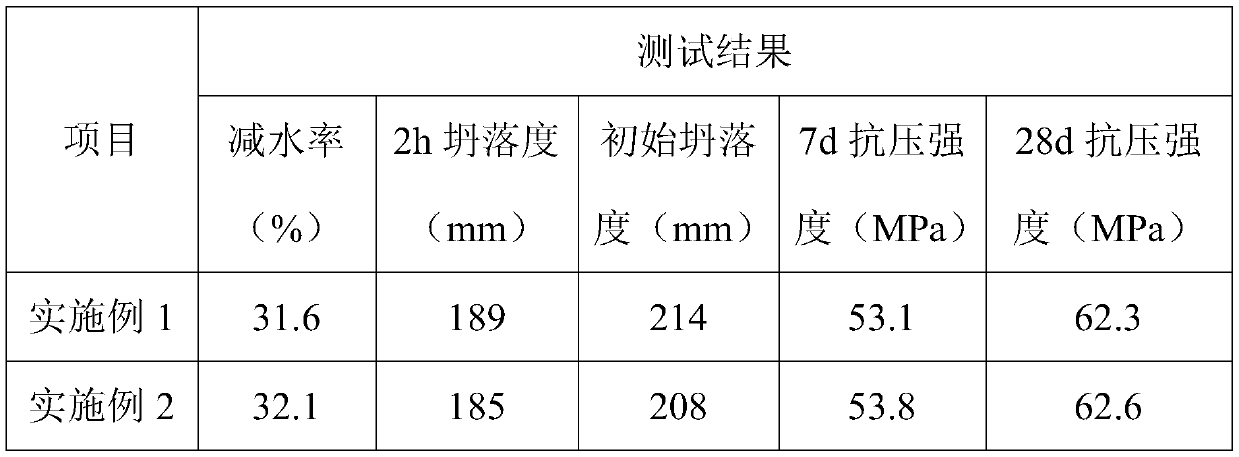

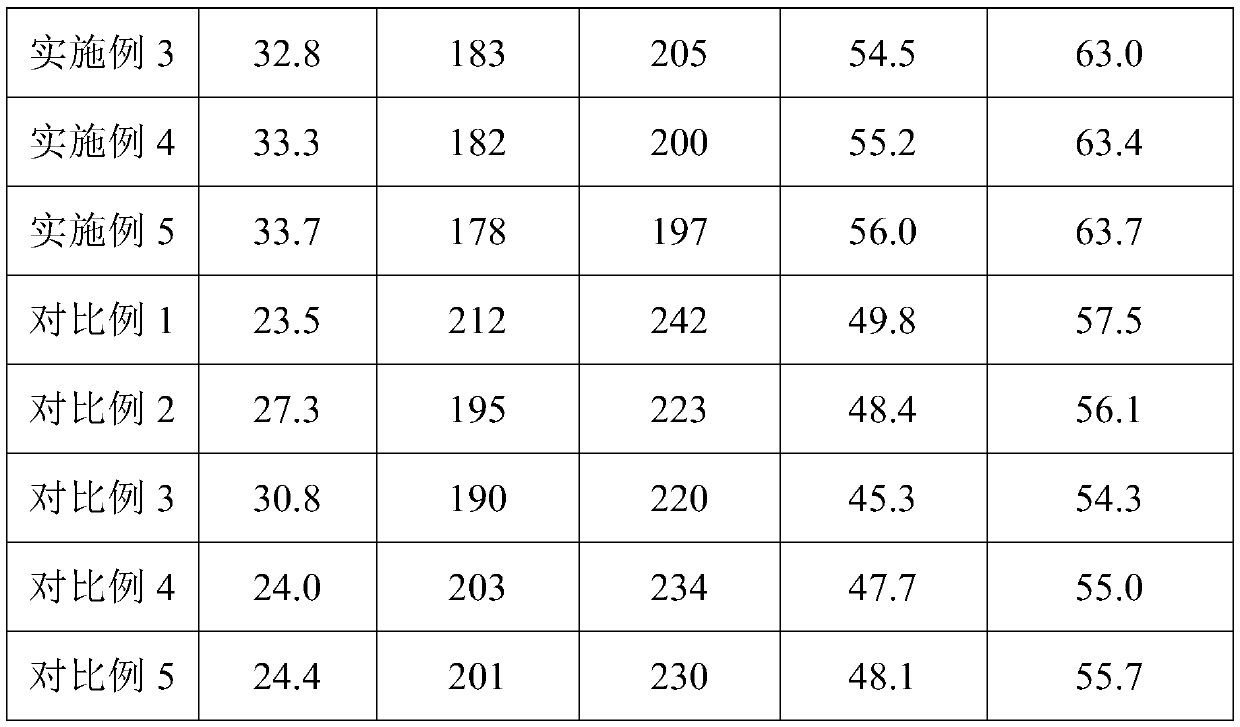

Anti-seepage and anti-cracking waterproof coating material with strong adhesion, and preparation method thereof

ActiveCN109554007AImprove performancePlay a role in reducing waterAntifouling/underwater paintsPaints with biocidesEmulsionCrystal

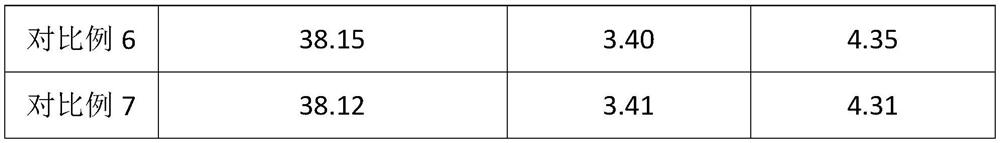

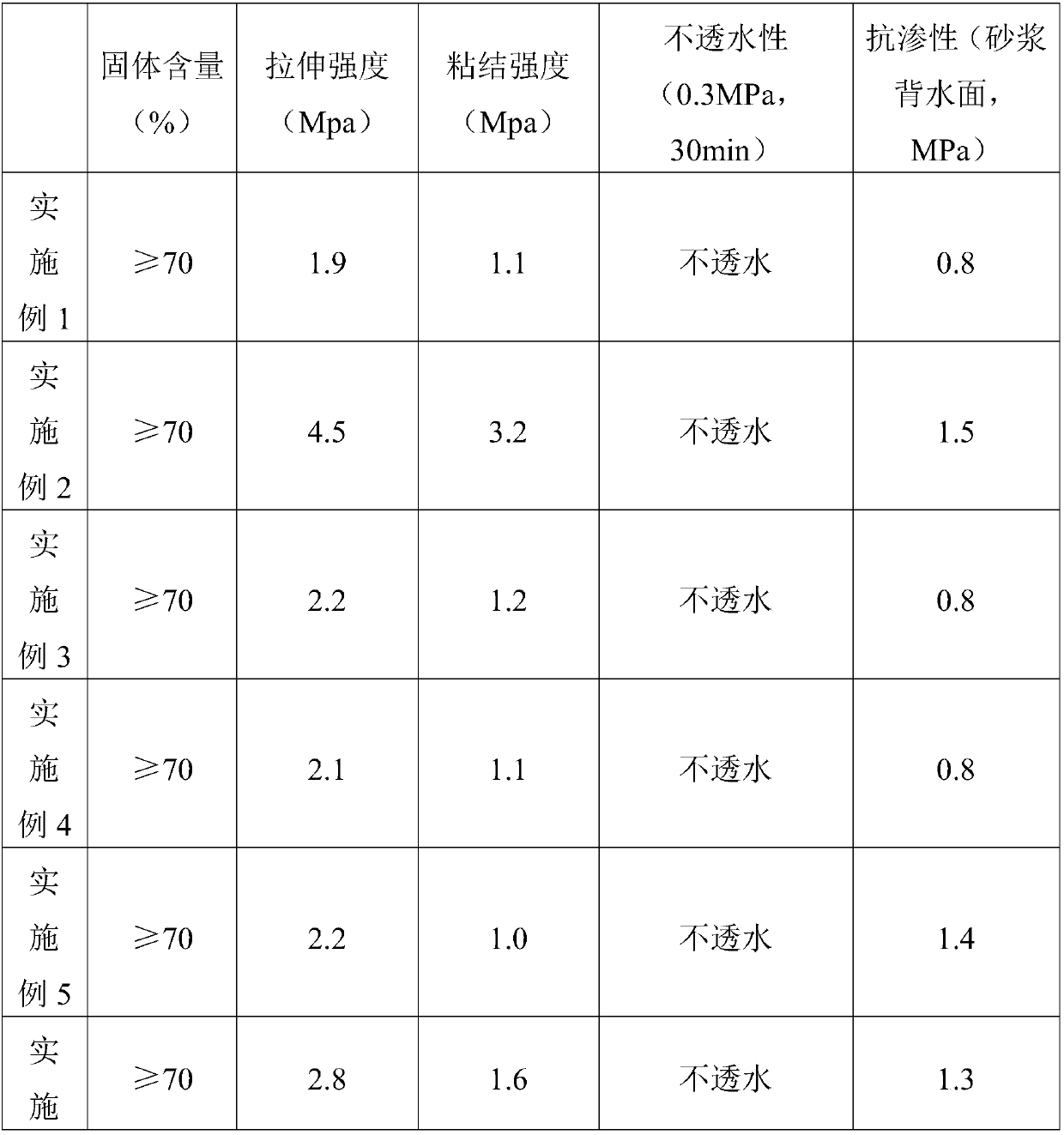

The invention provides an anti-seepage and anti-cracking waterproof coating material with strong adhesion, and a preparation method thereof, and belongs to the field of coating materials. According tothe present invention, the condition that the coating material cannot integrate high adhesion, high impermeability, high crack resistance and strong waterproof performance in the prior art is overcome by the coating material of the present invention, and the comprehensive waterproof coating material is provided; the coating material of the invention comprises a powder material and a liquid material, wherein the powder material comprises cement, quartz sand and a water reducing agent, and the liquid material comprises an emulsion, water, an antifoaming agent, a preservative and a dispersing agent; and the waterproof coating material of the invention has excellent waterproof performance, contains a certain active compound capable of penetrating into the interior of the substrate to form micro-expansion crystals so as to greatly improve the adhesion of the glue slurry, seal the water flow channel and achieve the optimal waterproof effect, and has the tensile strength of up to 4.5 MPa, the bond strength of up to 3.2 MPa and the impermeability of up to 1.5 MPa.

Owner:HUNAN XIANFENG BUILDING MATERIAL

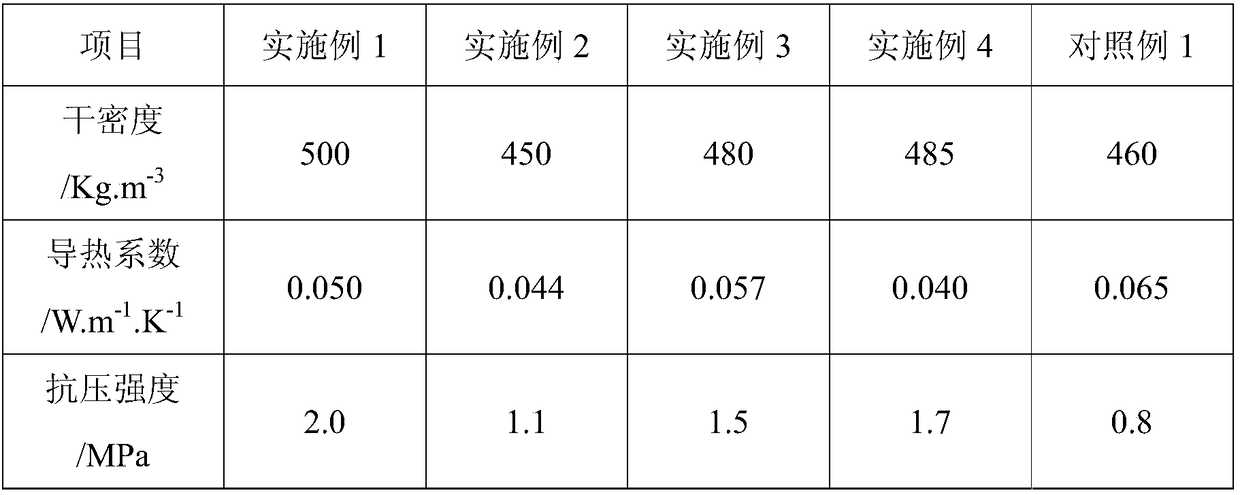

Building energy-saving thermal insulation material and preparation method thereof

The invention discloses a building energy-saving thermal insulation material, which is characterized being prepared from the following raw materials by weight: 15-25 parts of cement, 15-20 parts of blast furnace water granulated slag, 35-40 parts of volcanic ash, 5-8 parts of surface function modified porous hollow aluminum oxide nanofibers, 2-4 parts of rare earth fluoride hollow nano ions, 3-6 parts of Lambda-cyhalothric acid modified aminated beta-cyclodextrin and 1-3 parts of a coupling agent. The invention also discloses a preparation method of the building energy-saving thermal insulation material. The building energy-saving thermal insulation material disclosed by the invention is excellent in comprehensive performance, strong in thermal insulation property, good in aging resistance, weather resistance and flame retardance, excellent in performance stability and mechanical property, green and environment-friendly in use, high in durability, weather resistance, corrosion resistance, freeze thawing resistance and reliability, and wide in application range.

Owner:康亚男

Multi-sulfonate type cement water reducing agent and preparation method thereof

The invention discloses a multi-sulfonate type cement water reducing agent and a preparation method thereof, and belongs to the technical field of fine chemical product preparation. The multi-sulfonate type cement water reducing agent is prepared from the following raw materials: allyl polyoxyethylene ether, acid anhydride, a catalyst and NaHSO3. The preparation method comprises the following steps: firstly, mixing allyl polyoxyethylene ether, acid anhydride and the catalyst, heating and continuously stirring to react for 6-10 hours, so as to generate a polymer with double bonds at two ends and the middle part; adjusting the temperature, and dropping NaHSO3, thereby preparing the multi-sulfonate type cement water reducing agent. The preparation method disclosed by the invention is simple and convenient to operate, easy in process control, low in equipment requirement, environment-friendly, and applicable to industrialization large-scale production. The multi-sulfonate type cement water reducing agent prepared by using the method is excellent in water reduction property and dispersion property.

Owner:SHAANXI UNIV OF SCI & TECH

Cement concrete water reducing agent suitable for machine-made sand

Belonging to the technical field of environmental protection building materials, the invention in particular relates to a cement concrete water reducing agent suitable for machine-made sand. According to a technical scheme, the cement concrete water reducing agent suitable for machine-made sand is composed of the following components by weight: 8-60 parts of carboxylated styrene butadiene rubber powder, 5-20 parts of potassium aliphatate soap, 10-30 parts of starch, and 10-40 parts of a sodium hydroxide solution. The water reducing agent provided by the invention has very good volume compatibility with machine-made sand, can effectively ensure dispersion of the water reducing agent in concrete, has high water reducing rate and good fluidity, and can obviously improve the fluidity and workability of cement concrete for machine-made sand.

Owner:UNIV OF JINAN

Fire-resistant foam concrete material and preparation method thereof

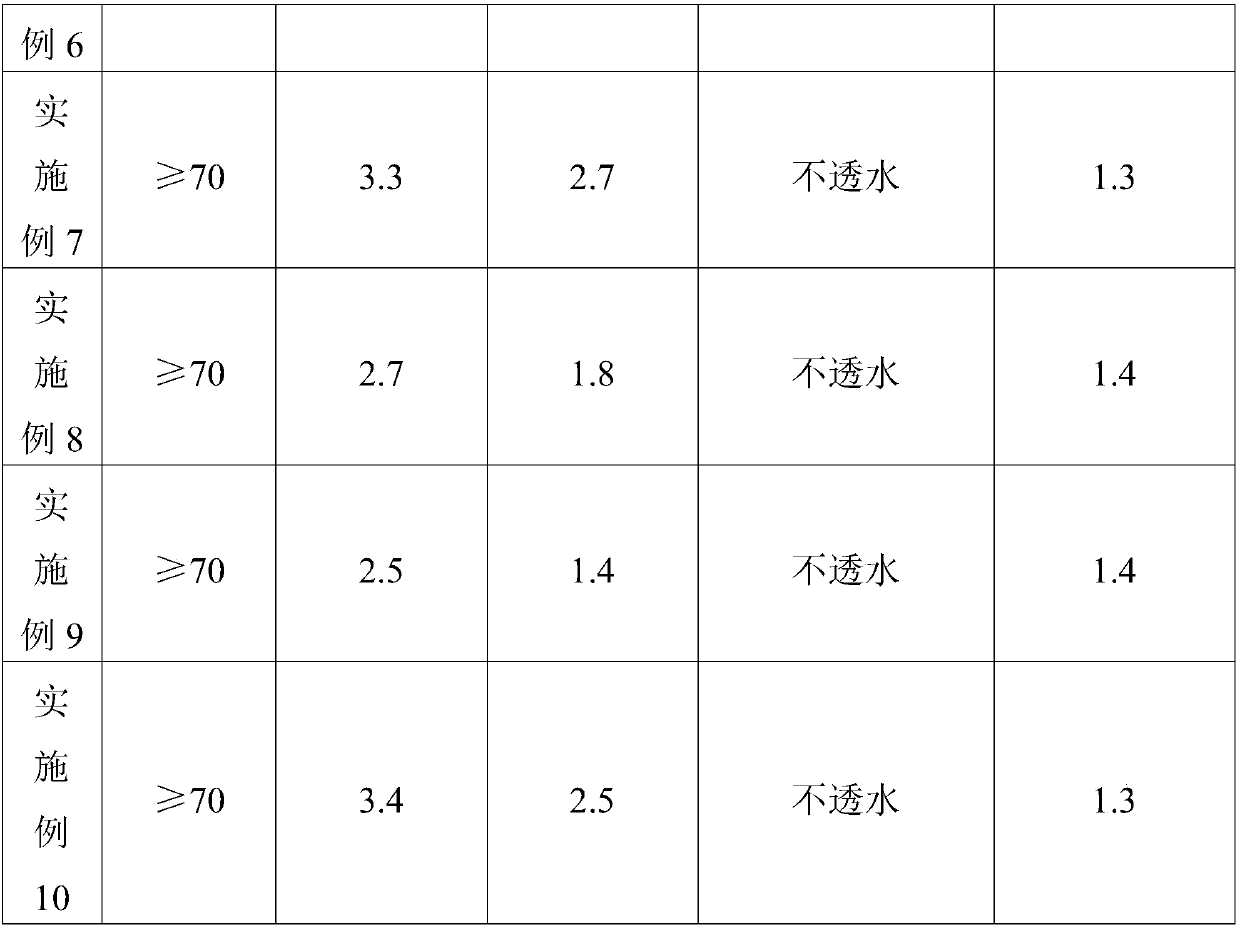

The invention discloses a fire-resistant foam concrete material and a preparation method thereof. The concrete material is prepared from the following raw materials in parts by weight: 240-300 parts of cement, 0.5-1 part of a water reducer, 1-2 parts of a foam stabilizer, 2-8 parts of early strength agent, 1.6-4 parts of a coagulant, 4-9 parts of fibers, 10-18 parts of a foaming agent, 40-60 partsof fly ash microspheres and 100-160 parts of water. The preparation method comprises the following steps that the cement, the fly ash microspheres, the early strength agent, the coagulant and the fibers are uniformly stirred, then the water, the water reducer and the foam stabilizer are added so as to prepare slurry, and finally the foaming agent is added for uniform mixing. The fire-resistant foam concrete material has the advantages of being good in fire resistance, light in weight, high in strength, good in heat preservation effect, low-carbon, energy-saving and environmentally friendly, alarge amount of industrial waste is utilized for preparing the raw materials, and important significance in the development of experiment economy and society is achieved.

Owner:SOUTHEAST UNIV

Concrete glue reducing agent and preparation method thereof

The invention discloses a concrete glue reducing agent and a preparation method thereof, relates to the technical field of concrete admixtures, and is characterized in that the concrete glue reducingagent is prepared by diluting mother liquor and water, and the 100 parts of mother liquor is prepared from the following components in parts by weight: 45-55 parts of mixed alcohol amine, 4-6 parts ofanhydrous sodium metasilicate, 5-7 parts of lithium silicate, 15-20 parts of methyl sodium silicate and the balance of water. The concrete glue reducing agent disclosed by the invention has the advantages that the cement dosage can be reduced, and the fluidity of a concrete mixture and the coating property of cement on aggregate are improved, so that the workability of concrete is improved.

Owner:深圳市三绿科技有限公司

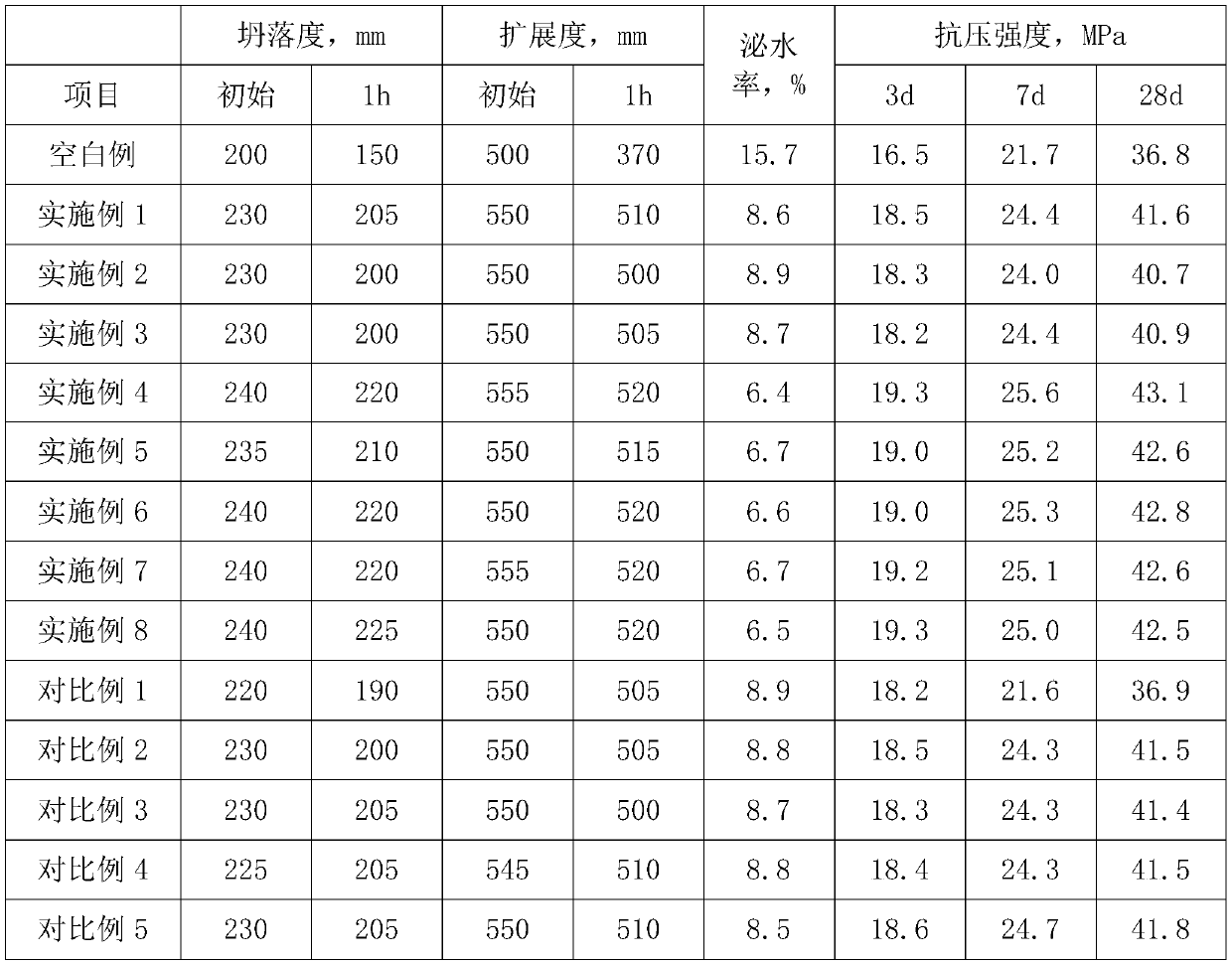

Fair-faced concrete and preparation method thereof

InactiveCN112341076ASimple manufacturing methodEasy to operate and controlAggregate (composite)Metal-organic framework

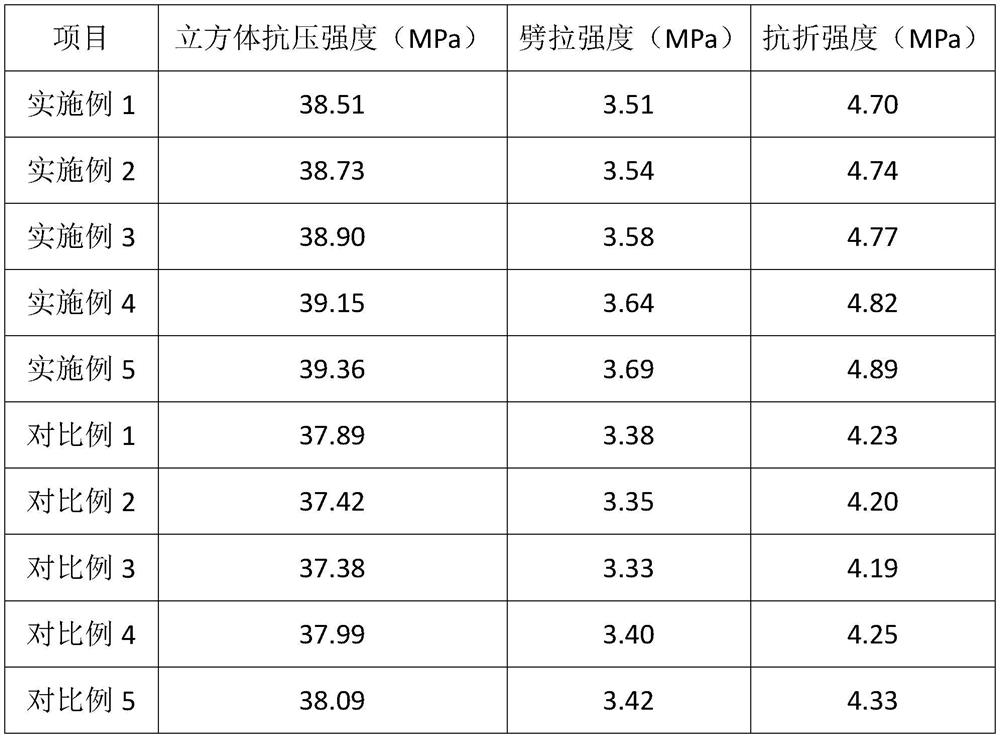

The invention discloses fair-faced concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanicash, 3-6 parts of nano hybrid hyperbranched polymer HB-SiO2, 75-85 parts of silica sand, 85-95 parts of coarse aggregate, 3-5 parts of basalt fibers, 1-3 parts of graphene oxide fibers, 7.5-8.5 partsof a composite additive, 15-20 parts of water, 1-3 parts of a carboxyl metal organic framework, 1-3 parts of zirconium citrate and 2-5 parts of zinc oxide nanofibers. The invention also provides a preparation method of the fair-faced concrete. The fair-faced concrete provided by the invention is better in comprehensive performance, higher in compressive strength and flowability, lower in bleedingrate, better in durability, environmental protection property and decorative effect, very good in appearance, smooth in surface and less in pores.

Owner:韩昌龙

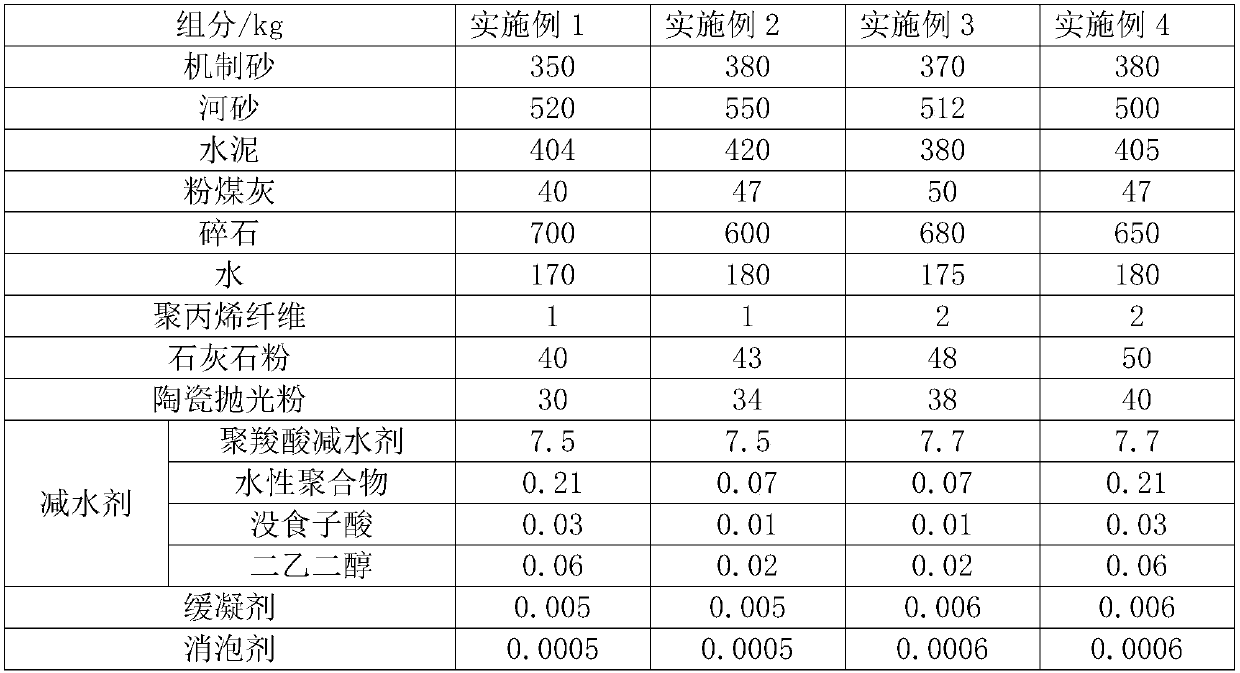

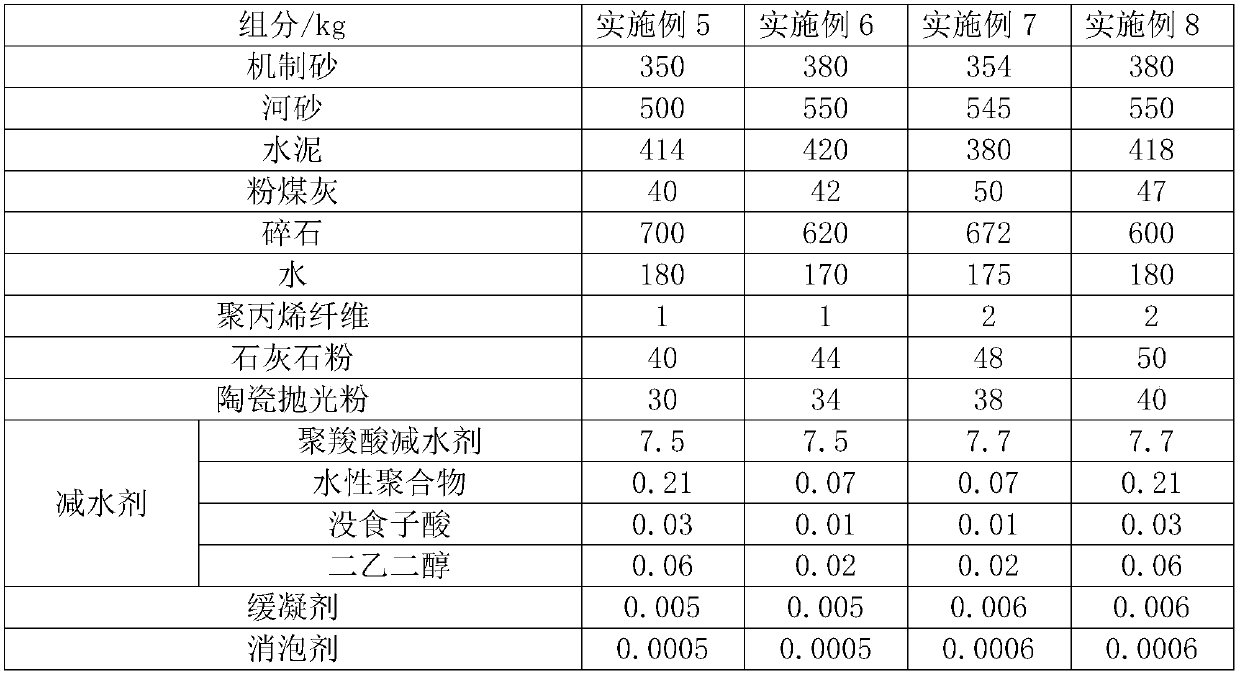

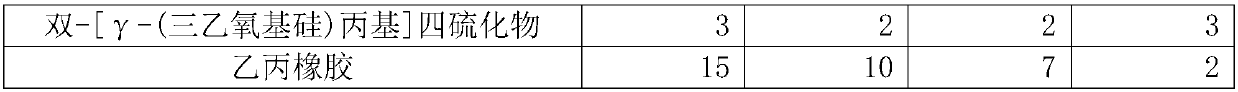

Machine-made sand concrete and preparation process thereof

InactiveCN109650803AImprove performanceImprove water retentionCrushed stoneUltimate tensile strength

The invention relates to machine-made sand concrete and a preparation process thereof. The preparation process comprises the following steps: step one, a first mixture is obtained after a water reducing agent and a retarder are first added into 50-80 parts of water and stirred uniformly, and then fly ash, cement, limestone powder and ceramic polishing powder are added and mixed uniformly; step two, a second mixture is obtained after river sand, machine-made sand, crushed stone, polypropylene fiber and residual water are added into the first mixture; step three, after the second mixture is stirred uniformly, a defoaming agent is added and stirred uniformly, and the machine-made sand concrete is made. The addition of polypropylene fiber in the components can improve the strength of the concrete. The limestone powder and the ceramic polishing powder can play a certain role in reducing water and improve the conditions that the content of stone powder in the machine-made sand is high and alarge amount of water is needed to a certain extent. In addition, the composite water reducing agent is selected as the water reducing agent, so that the dosage of the water reducing agent is reduced,the hydration of cement can be delayed, and the concrete has higher slump retention property.

Owner:陕西宏基混凝土构件有限责任公司

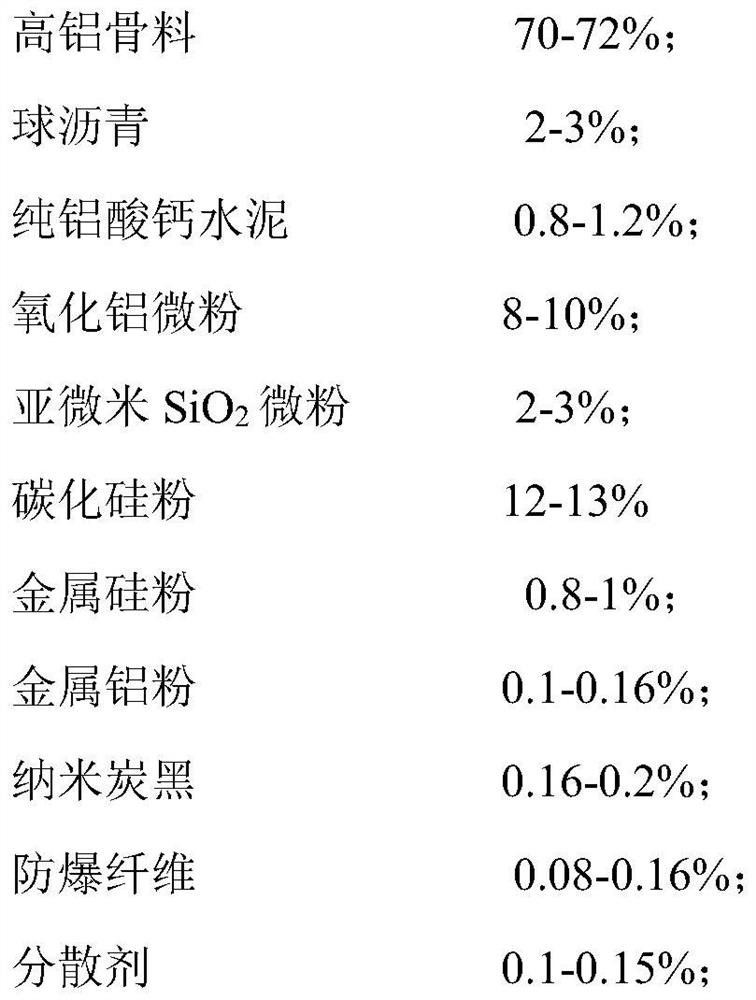

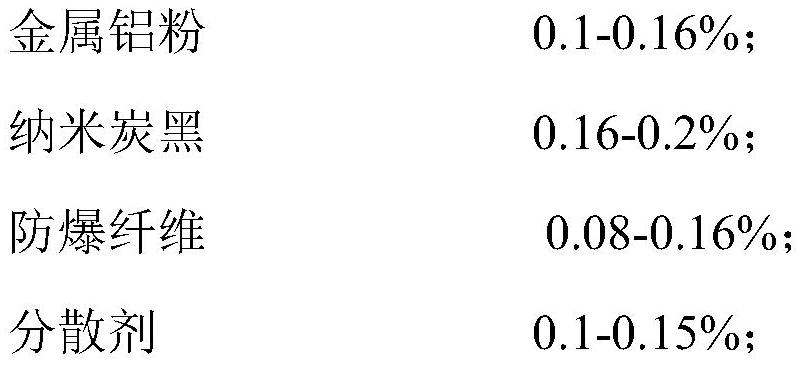

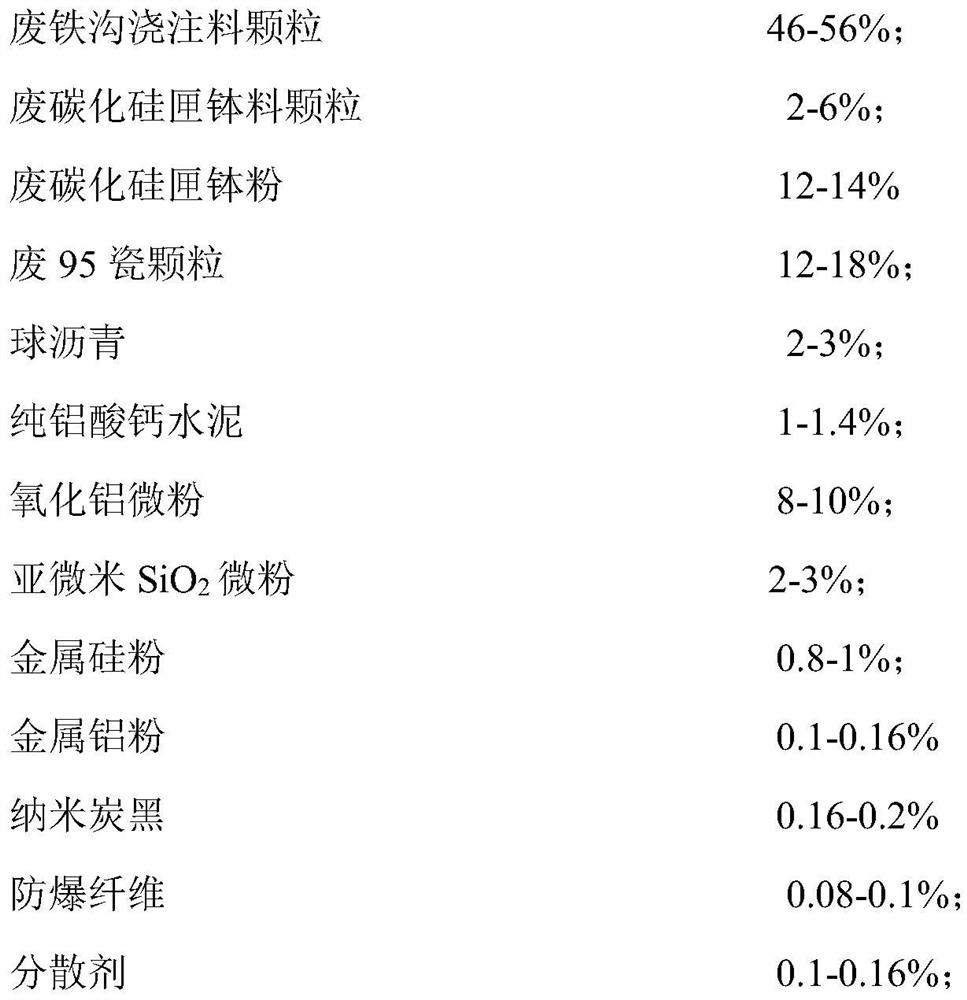

High-performance high-aluminum castable for iron runner

The invention discloses a high-performance and high-aluminum castable for an iron runner. The castable comprises the following components in percentage by mass: 70-72% of high-aluminum aggregate; 2-3% of ball pitch; 0.8%-1.2% of pure calcium aluminate cement; 8-10% of alumina micro powder; 2 to 3 percent of submicron SiO2 micro powder; 12-13% of silicon carbide powder; 0.8-1% of metal silicon powder; 0.1%-0.16% of metal aluminum powder; 0.16 to 0.2 percent of nano carbon black; 0.08 to 0.16 percent of explosion-proof fiber; and 0.1%-0.15% of a dispersing agent; and the product is prepared by adding 4.2% of water, uniformly stirring the components, and carrying out vibration molding. Through multiple technical measures, the compactness degree of the high-aluminum iron runner castable is improved to the maximum extent, meanwhile, a castable matrix generates fewer low-melting phases at high temperature, and through breakthrough enhancement of the performance of the powder matrix, the defect of the high-temperature performance of high-aluminum aggregate is counteracted, the problem that the thermal strength of the high-aluminum iron runner castable is obviously reduced compared with that of a corundum iron runner castable for a long time is solved, and the aim of completely replacing corundum aggregate with high-aluminum aggregate in a common iron runner castable is achieved.

Owner:中冶武汉冶金建筑研究院有限公司 +1

High performance antistatic self-leveling mortar

InactiveCN108726963ASmall shrinkageIncrease the speed of compoundingSolid waste managementWear resistantPolystyrene

The invention discloses high-performance antistatic self-leveling mortar. The high-performance antistatic self-leveling mortar is prepared from the following raw materials in parts by weight: 55 to 80parts of portland cement, 5 to 10 parts of sulphoaluminate cement, 10 to 15 parts of re-dispersible latex powder, 10 to 13 parts of fly ash, 0.35 to 1.5 parts of polypropylene fiber, 2 to 5 parts ofultrafine ettringite, 0.1 to 0.2 part of a water reducing agent, 0.1 to 0.2 part of an early strength agent, 0.15 to 0.3 part of a retarder, 0.15 to 0.3 part of a thickener, and 50 to 100-mesh waste polystyrene sheet broken particles. The high-performance antistatic self-leveling mortar has good fluidity, self-flow leveling, no need for vibration, simple construction, water addition, pumping pouring, and quick spreading; the mortar is wear-resistant and anti-cracking, smoothing in surface, fast and convenient in construction, has high hardening strength on the ground, excellent antistatic andwaterproof performance, can be made into colored ground of different colors, and is environmentally-friendly easy-to-operate self-leveling mortar.

Owner:安徽省万帮新型建材科技有限公司

Concrete pumping agent capable of preventing pipe blockage and water seepage

The invention discloses a concrete pumping agent capable of preventing pipe blockage and water seepage. The concrete pumping agent is characterized in being prepared from the following components in parts by weight: 4 to 7 parts of di (2-chloroethyl) hydrophosphate / piperazine-N, N-bis (2-hydroxyethane sulfonic acid) disodium salt polycondensate, 0.2 to 0.5 part of hyperbranched polyamino acid, 10to 15 parts of maleimide-tri (ethylene glycol)-propionic acid / triethanolamine oleate soap / vinyl phosphonic acid copolymer, 2 to 4 parts of kleemanite, 0.1 to 0.3 part of carboxymethyl chitosan and 30to 40 parts of water. The invention further provides a preparation method of the concrete pumping agent capable of preventing pipe blockage and water seepage. The concrete pumping agent disclosed by the invention is good in adaptability to cement, good in pumping effect, excellent in comprehensive performance, small in mixing amount, small in negative influence on the comprehensive performance ofconcrete, stable in quality and safe and environment-friendly to use, and the concrete added with the pumping agent is good in workability, excellent in pumpability and free of a water seepage phenomenon.

Owner:石旭艳

Recycled concrete

Belonging to the technical field of environment-friendly building materials, the invention discloses a recycled concrete, which comprises the following raw materials by weight: 230-330 parts of cement, 800-1300 parts of recycled aggregate, 200-400 portions of nickel-iron slag, 30-80 parts of a superfine admixture, 2-5 parts of a water reducer, 0.01-0.5 part of a retarder, 0.5-3 parts of a shrinkage reducing agent, 0.1-1 part of a reinforcing agent, 0.01-0.05 part of an air entraining agent, and 108.5-126 parts of water. The recycled concrete provided by the invention makes heavy use of waste concrete, nickel-iron slag, ceramic tile polishing powder, silicon carbide waste and other solid waste, reduces the mining of natural sand and stone, and is conducive to the construction of ecologicalcivilization.

Owner:河北雄安昝岗混凝土有限公司

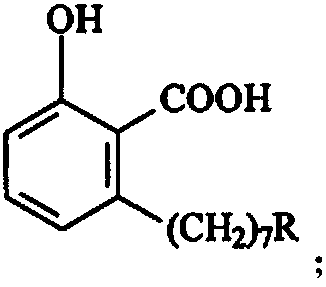

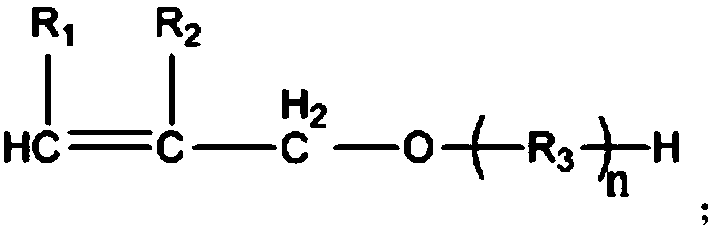

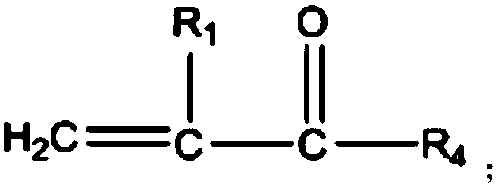

A kind of polycarboxylate water-reducer modified by gingkgolic acid grafting and preparation method thereof

Owner:WUHAN UNIV OF TECH

Cement-based waterproof material and preparation process thereof

The invention discloses a cement-based waterproof material which is characterized in that: the cement-based waterproof material comprises the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanic ash, 1-3 parts of fluorgypsum, 4-8 parts of hydrophilic nitrogen-doped carbon nanofibers, 2-5 parts of a hyperbranched 4A molecular sieve, 1-3 parts of epoxy organic fluorosilicone oil, 5-10 parts of sulfonated SBS, 3-5 parts of a hyperbranched sulfonate surfactant SHBP-1, 8-12 parts of 2-acrylamido-2-methylpropanesulfonic acid / N-trihydroxymethyl methacrylamide / vinyltriethoxysilane / 3, 5-diamino-1H-pyrazole-4-allyl carboxylate copolymer, 0.1-0.3 part of aluminum acrylate, 0.1-0.2 part of water-soluble initiator and 20-30 parts of water. The invention also provides a preparation method of the cement-based waterproof material. The cement-based waterproof material provided by the invention is excellent in comprehensive performance and performance stability, strong in matrix deformation adaptability, sufficient in toughness and bonding strength, compact in structure, better in waterproof performance and durability and longer in service life.

Owner:泗县邺霖建筑科技有限公司

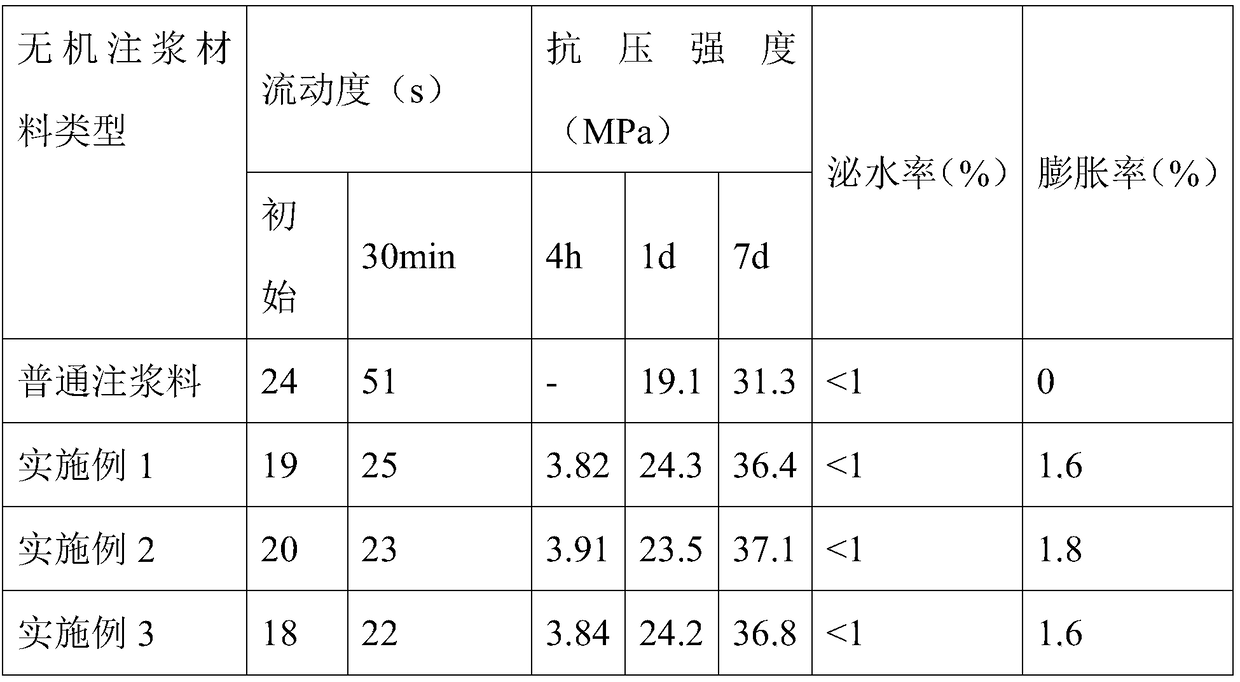

Inorganic grouting material for repairing semirigid base layer crack and preparation method thereof

The invention discloses an inorganic grouting material for repairing a semirigid base layer crack and a preparation method thereof, and belongs to the field of road repair. The inorganic grouting material is characterized by being prepared from the following ingredients of water-based epoxy latex, Portland cement, ore powder, expansion agents, NaOH, polycarboxylate superplasticizers, hydroxymethylcellulose, long chain alkylolamides and water according to the preparation method with the steps of S1, adding weighed ore powder, Portland cement, hydroxymethyl cellulose and expansion agents into astirring pot to be stirred; S2, mixing the weighed water-based epoxy latex, long chain alkylolamides, polycarboxylate superplasticizers, NaOH and water; performing stirring; S3, adding materials obtained in S2 into the materials obtained in S1; performing stirring to obtain an inorganic grouting material. The designed inorganic grouting material has high flowability, seepage performance and excellent mechanical performance; the semi-rigid base layer crack can be repaired; the traffic can be fast developed; the influence of pavement construction on the public traveling is reduced.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

High-corrosion-resistance ocean engineering material and preparation method thereof

The invention provides a high-corrosion-resistance ocean engineering material and a preparation method thereof. The ocean engineering material is prepared from, by weight, 40-60 parts of Portland cement, 5-10 parts of silica fume, 1-3 parts of nanometer silicon, 1-2.5 parts of a super plasticizer, 5-10 parts of a compacting agent, 0.01-0.03 part of a defoaming agent and 30-50 parts of a fine aggregate; and the Portland cement, the silica fume and the nano silicon are uniformly mixed through scientific preparation and are effectively compounded with a certain amount of the super plasticizer, the densifying agent, the defoaming agent and the fine aggregate, all the components cooperate with one another to play a role, the compressive strength of the ocean engineering material is remarkably improved and can reach 150 MPa or above, and the ocean engineering material has the characteristics of good compactness and high corrosion resistance and can be widely applied to the field of ocean engineering. The durability of the material in a marine environment is improved.

Owner:汪峻峰

Glass fiber reinforced concrete material and preparation method thereof

InactiveCN111925166AReduce pollutionLow requirements for preparation conditionsMicrosphereCyclodextrin

The invention discloses a glass fiber reinforced concrete material. The glass fiber reinforced concrete material is characterized by being prepared from the following raw materials in parts by weight:30-40 parts of cement, 2-5 parts of zircon sand, 10-15 parts of surface-grafted beta-cyclodextrin glass fibers, 3-6 parts of waste gypsum, 10-20 parts of volcanic ash, 20-30 parts of gravels, 60-80 parts of fine river sand, 4-8 parts of sulfate-containing organic silicon microspheres, 3-6 parts of additives and 15-20 parts of water. The glass fiber reinforced concrete material also comprises thefollowing preparation raw materials: 3-6 parts of rare earth fluoride nanofibers and 1-3 parts of zinc oxide mesoporous nanofibers. The invention also provides a preparation method of the glass fiberreinforced concrete material. The glass fiber reinforced concrete material disclosed by the invention is good in interface bonding effect and compatibility among the components, good in comprehensiveperformance, high in toughness and bending strength, and excellent in durability and impermeability.

Owner:曹均云

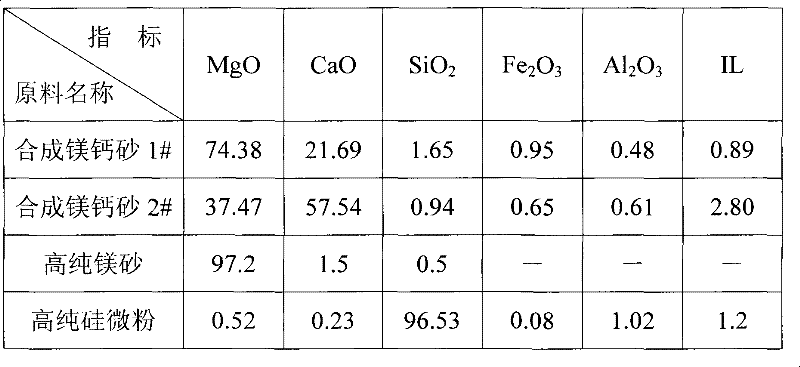

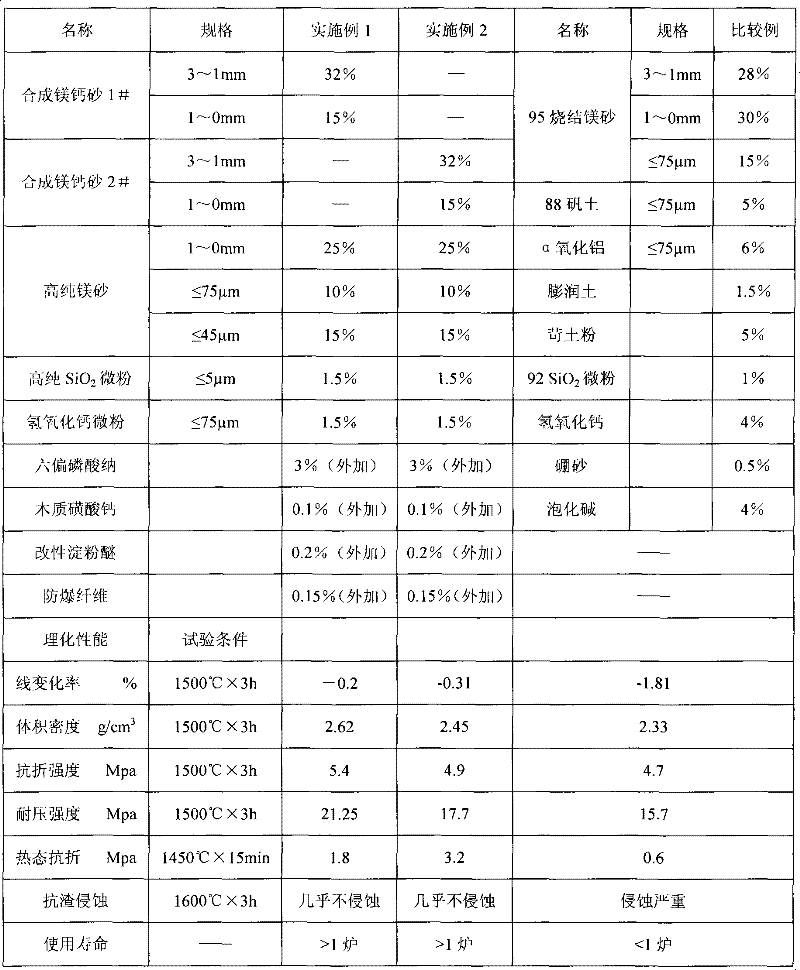

Magnesium calcium RH varnished tube hot spray repair material for smelting silicon steel and formulating method thereof

Owner:上海彭浦特种耐火材料厂有限公司

A kind of high-strength concrete and its preparation process

ActiveCN114163189BImprove production efficiencyReduce labor intensityOrganic chemistryHigh strength concreteButanedioic acid

The invention discloses a high-strength concrete, which comprises the following components in parts by weight: 80-100 parts of cement, 60-80 parts of coarse aggregate, 70-80 parts of fine aggregate, calixyrrole modified nano 5-8 parts of boron fiber, 1-3 parts of bromosuccinic acid ionized modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole, hyperbranched poly( Amine-ester) 0.5-1 part of acrylic acid, 5-8 parts of zeolite powder, 2-4 parts of boron carbide ceramic powder, 10-15 parts of attapulgite, 1-2 parts of carboxyl-terminated liquid nitrile rubber, 40-60 parts of water . The invention also discloses a preparation process of the high-strength concrete. The high-strength concrete disclosed by the invention has high flexural and compressive strength, sufficient toughness and long service life through the cooperation and mutual action of various components.

Owner:宁波龙峰混凝土有限公司

A super high temperature anti-skinning castable

The invention discloses a superhigh temperature anti-skinning castable. The castable comprises the following raw materials in parts by weight: 25-40 parts of corundum or alumina whose particle size is 5-1mm, 10-20 parts of silicon carbide whose particle size is 5-1mm, 5-15 parts of corundum or alumina whose particle size is 1-0.088mm, 10-26 parts of corundum whose particle size is less than 0.088mm, 2-8 parts of aluminum oxide micro powder, 2-6 parts of silica fume, 1-6 parts of aluminate cement, 0.1-0.3 parts of a decondensation agent, 0.005-0.05 parts of a retarder, 1-6 parts of silica sol, and 1-6 parts of water. The superhigh temperature anti-skinning castable has the advantages of good shaping performance and solidification performance, and after solidification, the castable has good high temperature resistance, erosion resistance, and thermal shock resistance.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Cementing material modifier as well as preparation method and application thereof

The invention relates to a cementing material modifier as well as a preparation method and application thereof. The raw materials of the modifier comprise the following components in parts by mass: 1000 parts of fly ash, 0.2-2.0 parts of triterpenoid saponin and 1-5 parts of xanthan gum. The preparation method comprises the following steps: mixing the fly ash, the triterpenoid saponin and the xanthan gum in parts by mass in a mixer to obtain the cementing material modifier. The cementing material modifier is applied to building materials. Compared with the prior art, the invention has the advantages of reducing viscosity, adjusting chromatic aberration, improving fluidity or workability and the like.

Owner:TONGJI UNIV

Environment-friendly concrete pumping agent and preparation method thereof

InactiveCN112456857AReduce manufacturing costReliable workmanshipHyperbranched polyesterCyclodextrin

The invention discloses an environment-friendly concrete pumping agent which is characterized by comprising the following components in parts by weight: 8-13 parts of sulfobutyl-beta-cyclodextrin sodium, 4-7 parts of 2-chloroethyl sodium sulfonate modified hydroxyl-terminated hyperbranched nano hybrid polymer, 3-5 parts of rosin-based hyperbranched polyester, 10-15 parts of a polycarboxylic acid high-performance water reducing agent, 0.1-0.3 part of a defoaming agent and 45-65 parts of water. The invention further discloses a preparation method of the environment-friendly concrete pumping agent. The environment-friendly concrete pumping agent disclosed by the invention is good in pumping effect, good in water reducing and retarding performance, capable of effectively controlling the slumploss of concrete, high in durability, free of bleeding, good in cement adaptability, stable in quality and environment-friendly in product.

Owner:姚小永

A cement concrete water reducing agent suitable for machine-made sand

Belonging to the technical field of environmental protection building materials, the invention in particular relates to a cement concrete water reducing agent suitable for machine-made sand. According to a technical scheme, the cement concrete water reducing agent suitable for machine-made sand is composed of the following components by weight: 8-60 parts of carboxylated styrene butadiene rubber powder, 5-20 parts of potassium aliphatate soap, 10-30 parts of starch, and 10-40 parts of a sodium hydroxide solution. The water reducing agent provided by the invention has very good volume compatibility with machine-made sand, can effectively ensure dispersion of the water reducing agent in concrete, has high water reducing rate and good fluidity, and can obviously improve the fluidity and workability of cement concrete for machine-made sand.

Owner:UNIV OF JINAN

Concrete waterproof anti-cracking agent and preparation method thereof

InactiveCN112500022AImprove pass rateSimple manufacturing methodSolid waste managementSulfonateHyperbranched polyester

The invention discloses a concrete waterproof anti-cracking agent which is characterized in that the concrete waterproof anti-cracking agent is prepared from the following components in parts by weight: 3-6 parts of porous beta-cyclodextrin crosslinked polymer nano-fibers, 10-15 parts of bauxite powder, 4-7 parts of a sulfonic acid group-containing fiber material, 20-30 parts of alunite, 8-12 parts of blast furnace slag, 2-4 parts of rosin-based hyperbranched polyester, 5-10 parts of sulfonate modified 2-amino adenine nucleoside, 3-5 parts of nano-boron fibers, and 2-5 parts of surface hydrophilic pig hair fibers. The invention also provides a preparation method of the concrete waterproof anti-cracking agent. The concrete waterproof anti-cracking agent disclosed by the invention is remarkable in waterproof anti-cracking effect, small in mixing amount, capable of effectively improving the comprehensive performance of concrete and good in environmental protection property.

Owner:杨井英

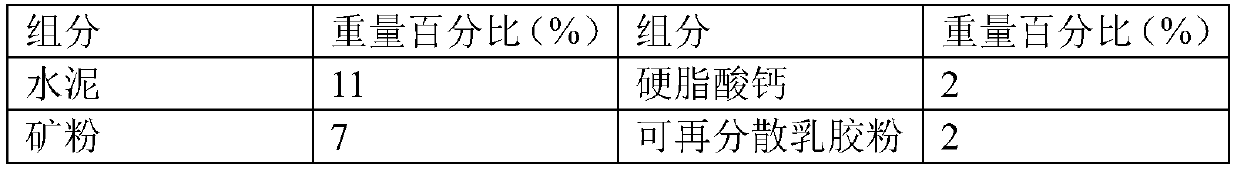

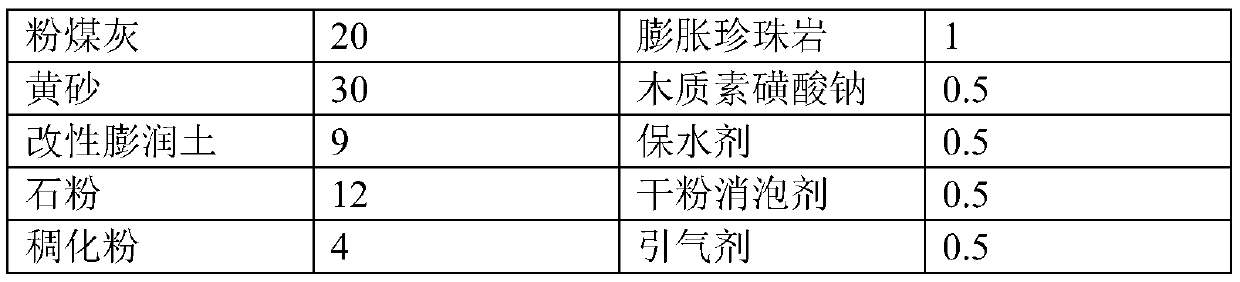

Dry-mixed mortar for pavement and preparation process thereof

The invention relates to dry-mixed mortar for a pavement and a preparation process of the dry-mixed mortar. The invention relates to the technical field of building materials. The dry-mixed mortar specifically comprises the following components in percentage by weight: 11-13% of cement, 6-8% of mineral powder, 17-20.5% of fly ash, 26-33% of yellow sand, 9-11% of modified bentonite, 10-13% of stonepowder, 2.5-4% of thickening powder, 1-2% of waterproof agent, 1-2.5% of redispersible latex powder, 1-2% of expanded perlite and 1.5-3% of an additive. The preparation method of the modified bentonite is as follows: 1) adding 20-30kg of glucose into 300-400L of water and stirring until the glucose is completely dissolved; 2) continuously adding 100-120 kg of bentonite and continuously stirring to uniformly disperse the bentonite; 3) adjusting the pH to 12-13, then raising the temperature to 80-120 deg c, stirring for 4-6 hours, centrifuging after stirring, washing the precipitate with waterfor 3-5 times, and drying. The mortar prepared by the method has the effects of good wear resistance, long service life of the pavement and reduction of maintenance cost of the pavement when laid on the pavement.

Owner:宁波新广亿建材有限公司

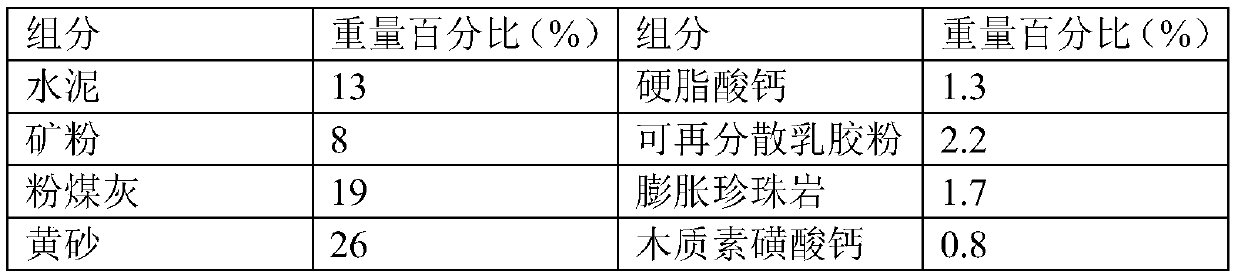

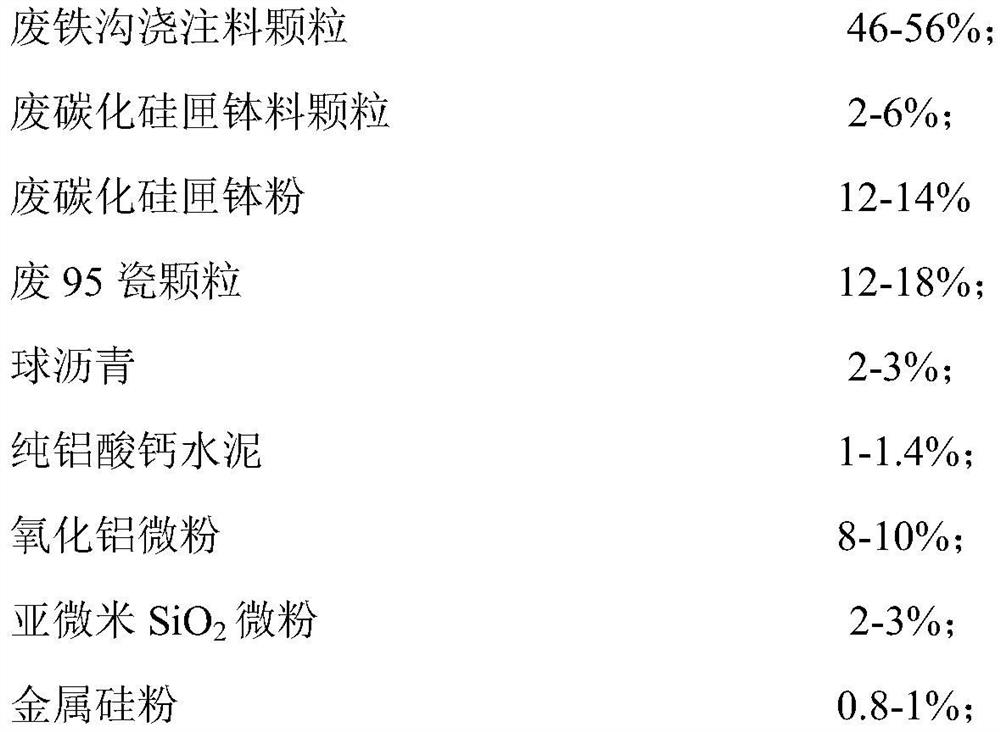

Novel iron runner castable with waste refractory as main material

ActiveCN113526967ASolve the problem of high temperature performance degradationBreak through the water limitAl powderFiber

The invention provides a novel iron runner castable with a waste refractory as a main material. The novel iron runner castable comprises the following components in percentage by mass: 46-56% of waste iron runner castable particles; 2-6% of waste silicon carbide sagger material particles; 12-14% of waste silicon carbide sagger powder; 12-18% of waste 95 ceramic particles; 2-3% of ball pitch; 1-1.4% of pure calcium aluminate cement; 8-10% of alumina micro powder; 2-3% of submicron SiO2 micro powder; 0.8-1% of metal silicon powder; 0.1%-0.16% of metal aluminum powder; 0.16- 0.2% of nano carbon black; 0.08-0.1% of explosion-proof fiber; and 0.1%-0.16% of a dispersing agent; and the iron runner castable is formed by uniformly stirring the above components and 5% of water by performing vibration molding. According to the iron runner castable, various waste materials are fully utilized, so that the comprehensive cost of the iron runner castable is greatly reduced; and meanwhile, industrial application proves that the iron runner castable disclosed by the invention is good in field use effect, high in batch production operability, excellent in physical property and good in quality stability, and is suitable for each part of a casting house.

Owner:中冶武汉冶金建筑研究院有限公司 +1

A kind of concrete reducer and preparation method thereof

The invention discloses a concrete glue reducer and a preparation method thereof, and relates to the technical field of concrete admixtures. The main point of the technical solution is a concrete glue reducer, which is prepared by diluting a mother liquor with water, and calculated as 100 parts by weight of the mother liquor. It includes the following components: 45-55 parts of mixed alcohol amine, 4-6 parts of anhydrous sodium metasilicate, 5-7 parts of lithium silicate, 15-20 parts of sodium methyl silicate, and the balance is water. The concrete glue reducer of the invention has the advantages of reducing the amount of cement used, improving the fluidity of the concrete mixture and the encapsulation of the aggregate by the cement, thereby improving the workability of the concrete.

Owner:深圳市三绿科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com