Inorganic grouting material for repairing semirigid base layer crack and preparation method thereof

A semi-rigid base and grouting material technology, applied in the field of road repair, can solve the problems of cement slurry volume shrinkage, easy precipitation and water precipitation, large diameter of cement particles, etc., to improve impermeability and durability, and good volume stability Sexuality, the effect of early strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

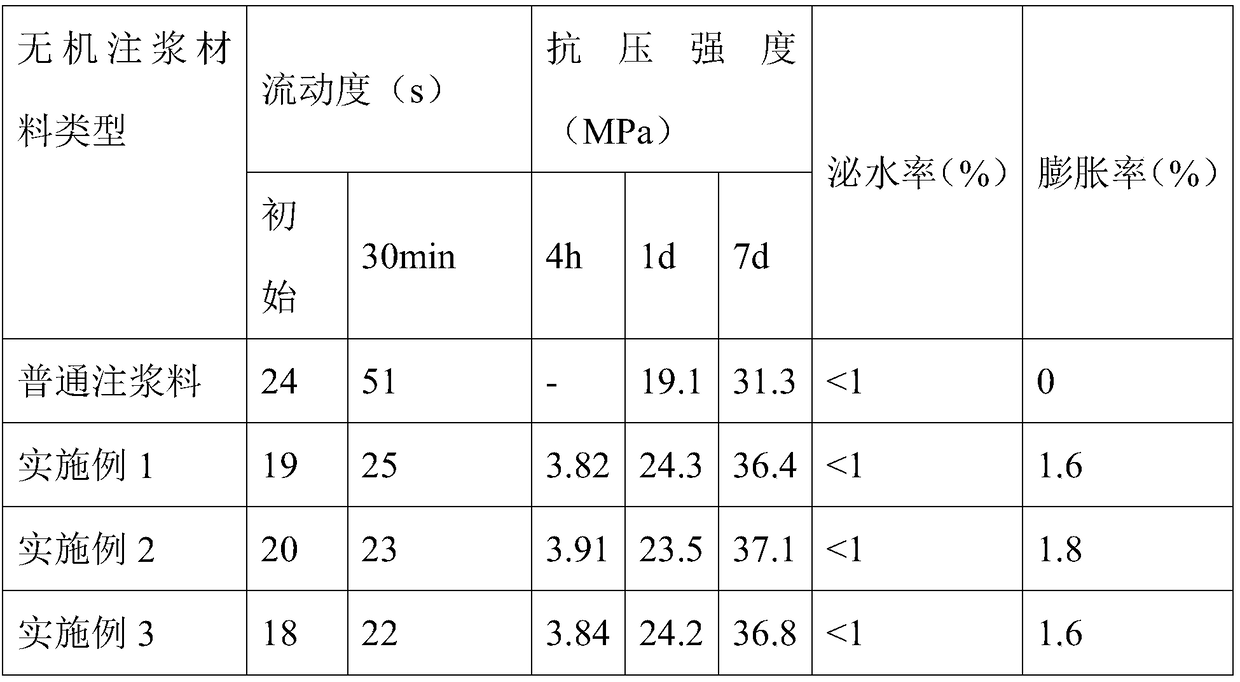

Examples

Embodiment 1

[0024] Example 1 A preparation method of an inorganic grouting material for repairing cracks in a semi-rigid base

[0025] S1. Add 20 parts of superfine S105 mineral powder, 69 parts of superfine Portland cement, 1 part of hydroxymethyl cellulose and 10 parts of UEA expansion agent into the mixing pot and stir for 1 to 2 minutes;

[0026] S2. Mix 5 parts of water-based epoxy latex, 2 parts of 2-octyldecanol, 0.002 parts of shrinkage-reducing polycarboxylate superplasticizer, 2 parts of NaOH and 35 parts of water and stir for 30s to 90s;

[0027] S3. Add S2 to S1 and add it while stirring. After adding S2, continue stirring for 60s~90s to obtain inorganic grouting material.

Embodiment 2

[0028] Example 2 A preparation method of an inorganic grouting material for repairing cracks in a semi-rigid base

[0029] S1. Add 30 parts of superfine S105 mineral powder, 63 parts of superfine Portland cement, 2 parts of hydroxymethyl cellulose and 5 parts of UEA expansion agent into the mixing pot and stir for 1 to 2 minutes;

[0030] S2. Mix and stir 10 parts of water-based epoxy latex, 4 parts of erucamide, 0.004 parts of shrinkage-reducing polycarboxylate superplasticizer, and 40 parts of water for 30s to 90s;

[0031] S3. Add S2 to S1 and add it while stirring. After adding S2, continue stirring for 60s-90s to obtain inorganic grouting material.

Embodiment 3

[0032] Example 3 A preparation method of an inorganic grouting material for repairing cracks in a semi-rigid base

[0033] S1. Add 25 parts of superfine S105 mineral powder, 65.5 parts of superfine Portland cement, 1.5 parts of hydroxymethyl cellulose and 8 parts of UEA expansion agent into the mixing pot and stir for 1 to 2 minutes;

[0034] S2. Mix 8 parts of water-based epoxy latex, 3 parts of arachidamide, 0.005 parts of shrinkage-reducing polycarboxylate superplasticizer, 1 part of NaOH and 40 parts of water and stir for 30s to 90s;

[0035] S3. Add S2 to S1 and add it while stirring. After adding S2, continue stirring for 60s-90s to obtain inorganic grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com