Fire-resistant foam concrete material and preparation method thereof

A foamed concrete, fire-resistant technology, applied in the field of building materials, can solve the problems of waste of manpower, material resources, financial resources, high temperature resistance, poor fire safety, and difficulty in recycling and reuse, so as to reduce fire losses, improve fire resistance, and improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

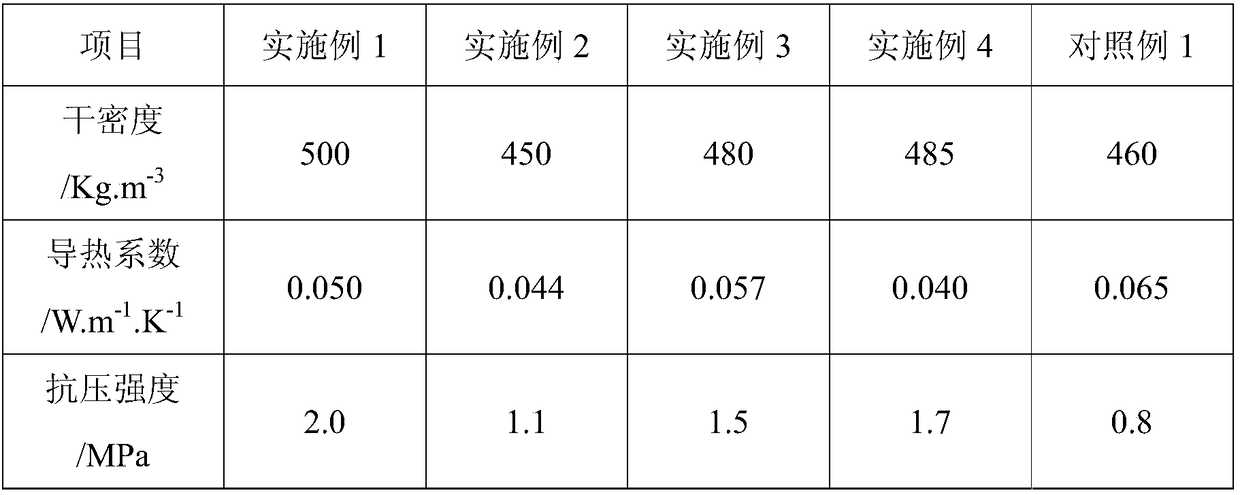

Examples

Embodiment 1

[0032] A fire-resistant foam concrete material, consisting of the following raw materials by weight:

[0033] 240 parts cement,

[0034] 1 part high-efficiency polycarboxylate superplasticizer,

[0035] 1 part foam stabilizer (sodium stearate),

[0036] 8 parts of early strength agent (triethanolamine),

[0037] 4 parts coagulant (sodium aluminate),

[0038] 9 parts fiber,

[0039] 10 parts blowing agent (hydrogen peroxide),

[0040] 60 parts fly ash microbeads,

[0041] 160 parts water.

[0042] Its preparation method is:

[0043] Add 240 parts of cement, 60 parts of fly ash microbeads, 8 parts of triethanolamine, 4 parts of sodium aluminate, and 9 parts of fiber into the mortar mixing pot, and then add 1 part of high-efficiency polycarboxylate superplasticizer and sodium stearate 1 part and 160 parts of water to prepare a slurry, and finally add 10 parts of hydrogen peroxide and stir evenly to obtain the refractory foam concrete material.

Embodiment 2

[0045] A fire-resistant foam concrete material, consisting of the following raw materials by weight:

[0046] 300 parts cement,

[0047] 0.5 parts of high-efficiency polycarboxylate superplasticizer,

[0048] 1 part foam stabilizer (gum arabic),

[0049] 2 parts accelerator (triisopropanolamine),

[0050] 1.6 parts coagulant (sodium sulfate),

[0051] 4 parts fiber,

[0052] 18 parts blowing agent (hydrogen peroxide),

[0053] 40 parts fly ash microbeads,

[0054] 100 parts water.

[0055] Its preparation method is:

[0056] Add 300 parts of cement, 40 parts of fly ash microbeads, 2 parts of triisopropanolamine, 1.6 parts of sodium sulfate, and 4 parts of fiber into the mortar mixing pot, and then add 0.5 parts of high-efficiency polycarboxylate superplasticizer and gum arabic 1 part and 100 parts of water to prepare a slurry, and finally add 18 parts of hydrogen peroxide and stir evenly to obtain the refractory foam concrete material.

Embodiment 3

[0058] A fire-resistant foam concrete material, consisting of the following raw materials by weight:

[0059] 270 parts cement,

[0060] 0.7 parts of high-efficiency polycarboxylate superplasticizer,

[0061] 1.5 parts of foam stabilizer (1 part of sodium stearate, 0.5 part of gum arabic),

[0062] 5 parts early strength agent (sodium formate),

[0063] 3 parts coagulant (sodium aluminate),

[0064] 7 parts fiber,

[0065] 14 parts blowing agent (hydrogen peroxide),

[0066] 50 parts fly ash microbeads,

[0067] 130 parts water.

[0068] Its preparation method is:

[0069] Add 270 parts of cement, 50 parts of fly ash microbeads, 5 parts of sodium formate, 3 parts of sodium aluminate, and 7 parts of fiber into the mortar mixing pot, and then add 0.7 parts of high-efficiency polycarboxylate superplasticizer and 1 part of sodium stearate. part, 0.5 part of gum arabic, and 130 parts of water to prepare a slurry, and finally add 14 parts of hydrogen peroxide and stir evenly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com