Cementing material modifier as well as preparation method and application thereof

A technology of cementitious materials and modifiers, applied in the field of building materials, can solve the problems affecting compactness, plastering efficiency and effect, not finding chemical water reducing agents, affecting appearance, etc., to achieve improved plastering efficiency and significant economic and social benefits , Improve the effect of construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cementitious material modifiers and building materials are prepared by:

[0027] (1) Mix 1000 parts of fly ash, 0.25 parts of triterpene saponins and 5 parts of xanthan gum in a mixer for 10-20 minutes to obtain a gelling material modifier.

[0028] (2) 1 part of cementitious material, 0.16 part of water and 1 part of sand are mixed, and fully stirred to form a slurry (mortar); wherein, the gelatinous material comprises 80ωt% brucite-phosphate-based cementitious material and 20ωt% cementitious material modifier (modifier dosage 20%); brucite-phosphate-based cementitious material is made up of 100 parts of ammonium dihydrogen phosphate, 200 parts of brucite and 25 parts of borax;

[0029] (3) Pour the slurry into the mold and solidify for 1-3 hours to form;

[0030] (4) Open the mold, take out the cured and formed slurry, and maintain it in the air for 3h-28 days, the temperature is 20±5°C, and the humidity is 70±10rh%. It is forbidden to directly put in water or spray ...

Embodiment 2

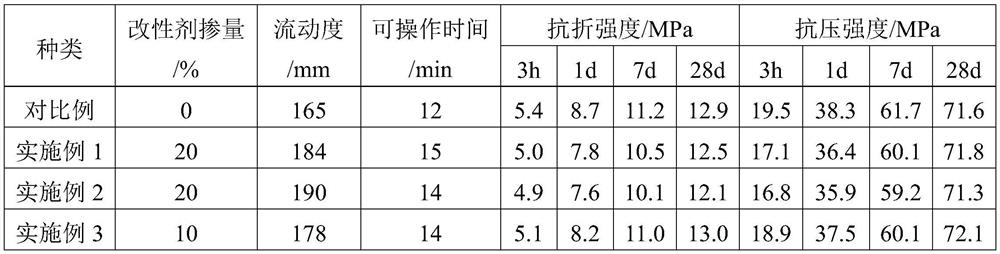

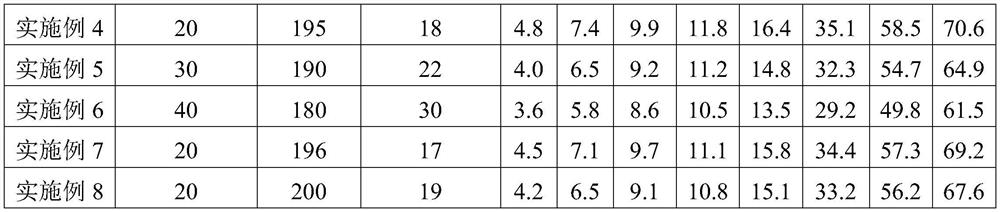

[0032] The difference from Example 1 is that the composition of the cementitious material modifier is: 1000 parts of fly ash, 0.5 parts of triterpene saponins, and 4 parts of xanthan gum. The performance indexes are shown in Table 1.

Embodiment 3

[0034] The difference with Example 1 is that the composition of the gelling material modifier is: 1000 parts of fly ash, 1.0 part of triterpene saponins, 3 parts of xanthan gum, and the gelling material comprises brucite-phosphoric acid of 90ωt%. The performance indexes of the salt-based gelling material and the 10ωt% gelling material modifier are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com