Concrete glue reducing agent and preparation method thereof

A glue reducer and concrete technology, which is applied in the field of concrete glue reducer and its preparation, can solve the problems of inhibiting the dispersion of glue reducer on cement particles, increasing the viscosity of concrete mixture, and affecting the encapsulation of cement to aggregate, etc. Achieve the effects of improving wrapping, reducing cement consumption, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

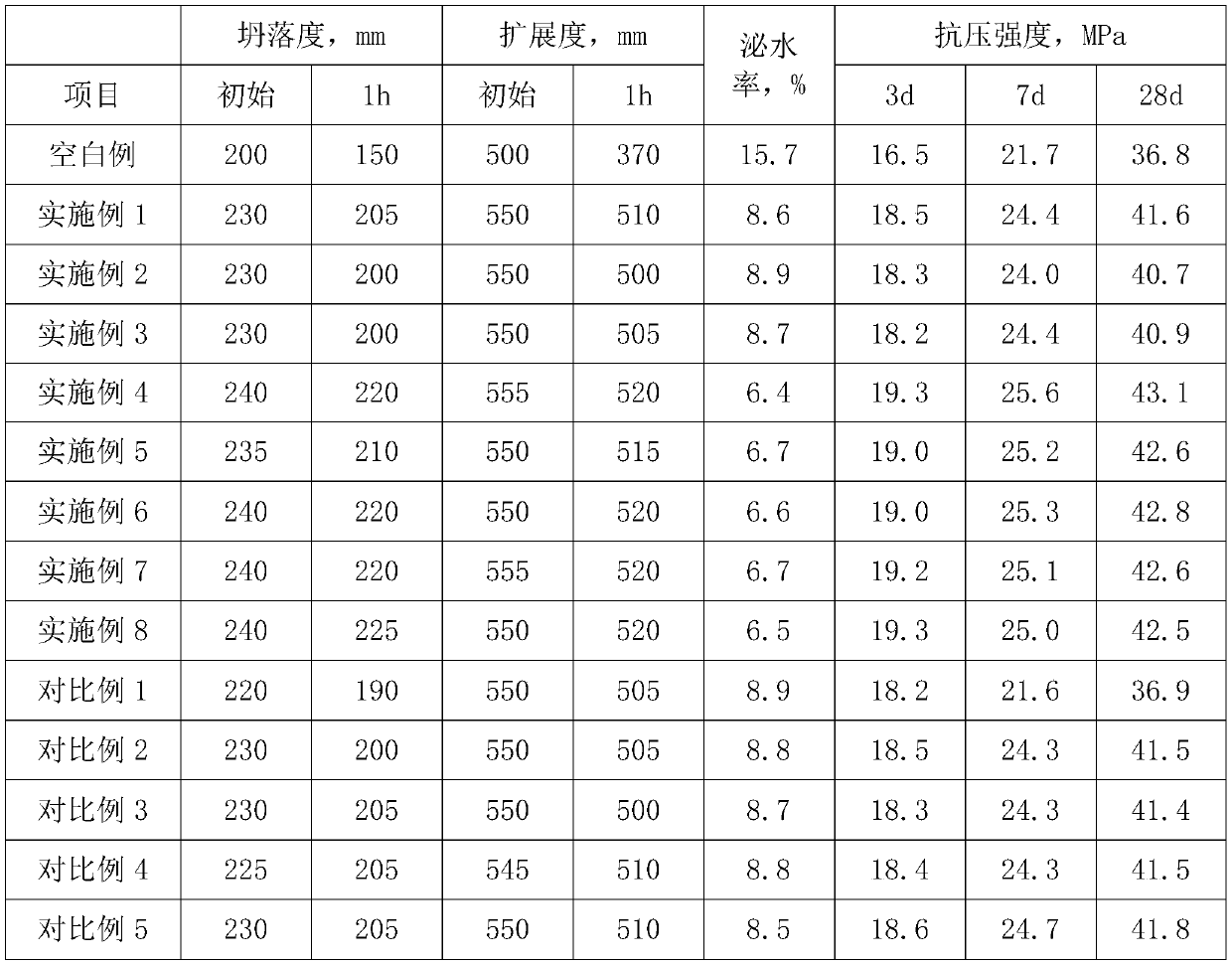

Examples

preparation example 1

[0037] Preparation example 1 of polycarboxylate water reducer: ① Take 12.5kg of acrylic acid, 4kg of acrylamide, 1.5kg of hydroxyethyl methacrylate, 0.3kg of isobutyl methacrylate, 2.5kg of sodium methacrylate, 0.25 kg alpha-alkenyl sulfonate sodium and 55kg water, stir evenly to obtain mixed solution A;

[0038] ②Take 0.15kg of mercaptopropionic acid, 0.3kg of ammonium persulfate, 0.1kg of ascorbic acid and 12.5kg of water, and mix well to obtain the mixed solution B;

[0039] ③Take 50kg of methallyl alcohol polyoxyethylene ether and 60kg of water, raise the temperature to 48°C, add the mixed solution B, stir for 1.5h, then add the mixed solution A, dropwise after 3.5h, then add 100kg of water, at 48°C At a certain temperature, keep stirring for 3.5 hours, and then add 10wt% sodium hydroxide solution to adjust the pH of the system to 7 to obtain a polycarboxylic acid-based water reducer.

preparation example 2

[0040] Preparation example 2 of polycarboxylate water reducer: ① Take 10kg of acrylic acid, 3kg of acrylamide, 1kg of hydroxyethyl methacrylate, 0.2kg of isobutyl methacrylate, 2kg of sodium methacrylate, 0.2kg of α-ene Sodium sulfonate and 50kg water are stirred evenly to obtain mixed solution A;

[0041] ②Take 0.1kg of thioglycolic acid, 0.225kg of ammonium persulfate, 0.075kg of ascorbic acid and 10kg of water, and mix well to obtain the mixed solution B;

[0042] ③Take 40kg of methallyl alcohol polyoxyethylene ether and 50kg of water, raise the temperature to 45°C, add the mixed solution B, stir for 1 hour, add the mixed solution A, drop it in 3 hours, then add 100kg of water, at a temperature of 45°C Then, keep stirring for 3 hours, and then add 10wt% sodium hydroxide solution to adjust the pH of the system to 6 to obtain a polycarboxylic acid-based water reducer.

preparation example 3

[0043] Preparation example 3 of polycarboxylate water reducer: ① Take 15kg of acrylic acid, 5kg of acrylamide, 2kg of hydroxyethyl methacrylate, 0.4kg of isobutyl methacrylate, 3kg of sodium methacrylate, 0.3kg of α-ene Sodium sulfonate and 60kg water are stirred evenly to obtain mixed solution A;

[0044] ②Take 0.2kg of mercaptopropionic acid, 0.375kg of ammonium persulfate, 0.125kg of ascorbic acid and 15kg of water, and mix well to obtain the mixed solution B;

[0045] ③Take 60kg of methallyl alcohol polyoxyethylene ether and 70kg of water, raise the temperature to 50°C, add the mixed solution B, stir for 2 hours, add the mixed solution A, drop it in 4 hours, then add 100kg of water, at a temperature of 50°C Then, keep stirring for 4 hours, then add 10wt% sodium hydroxide solution to adjust the pH of the system to 8 to obtain a polycarboxylic acid-based water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com