Anti-seepage and anti-cracking waterproof coating material with strong adhesion, and preparation method thereof

A waterproof coating and adhesion technology, applied in the field of coatings, can solve the problems of lack of comprehensiveness, deviation, shock resistance, poor thermal insulation, etc., and achieve the effect of improving comprehensive performance, prolonging action time, and excellent waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

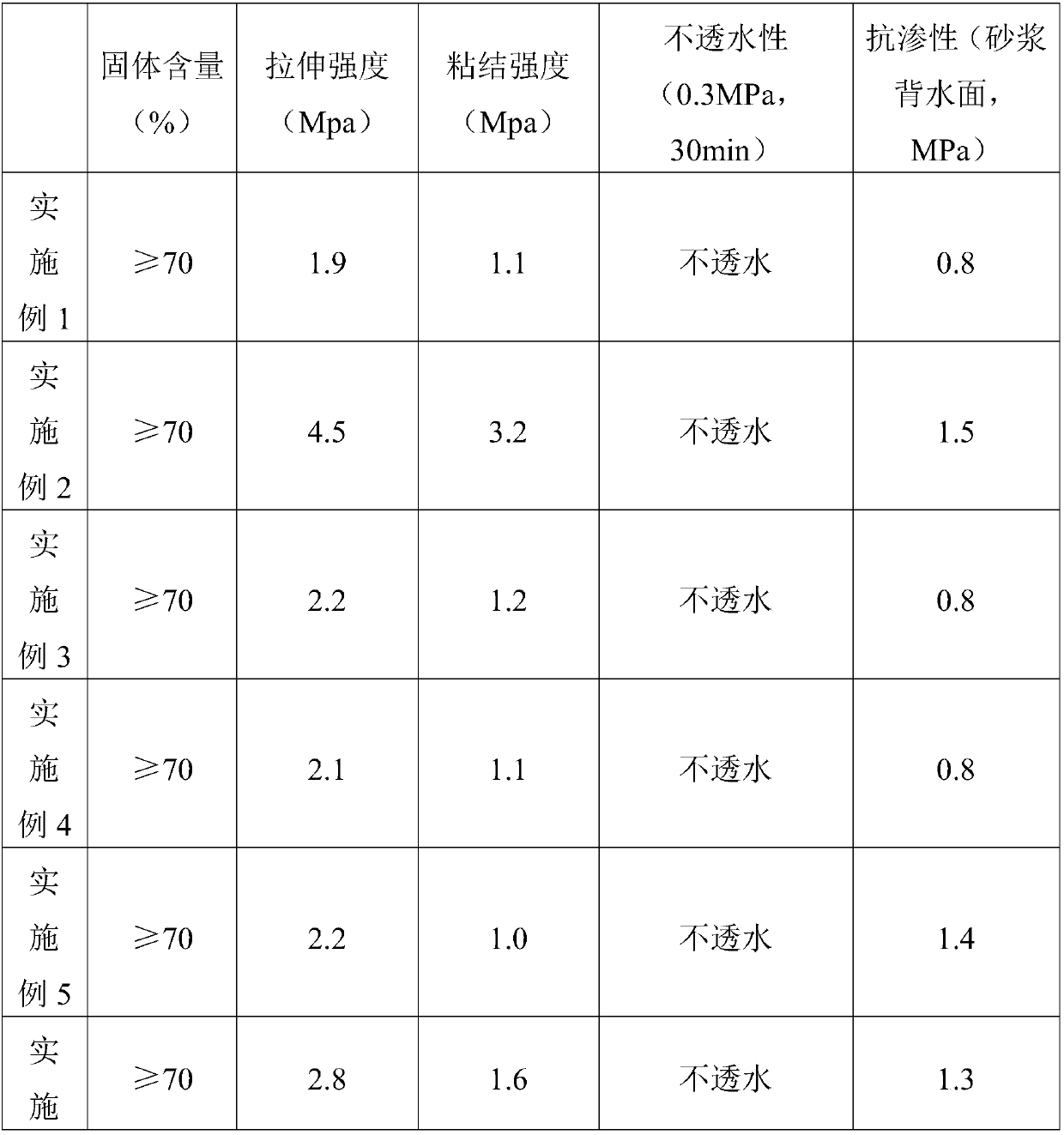

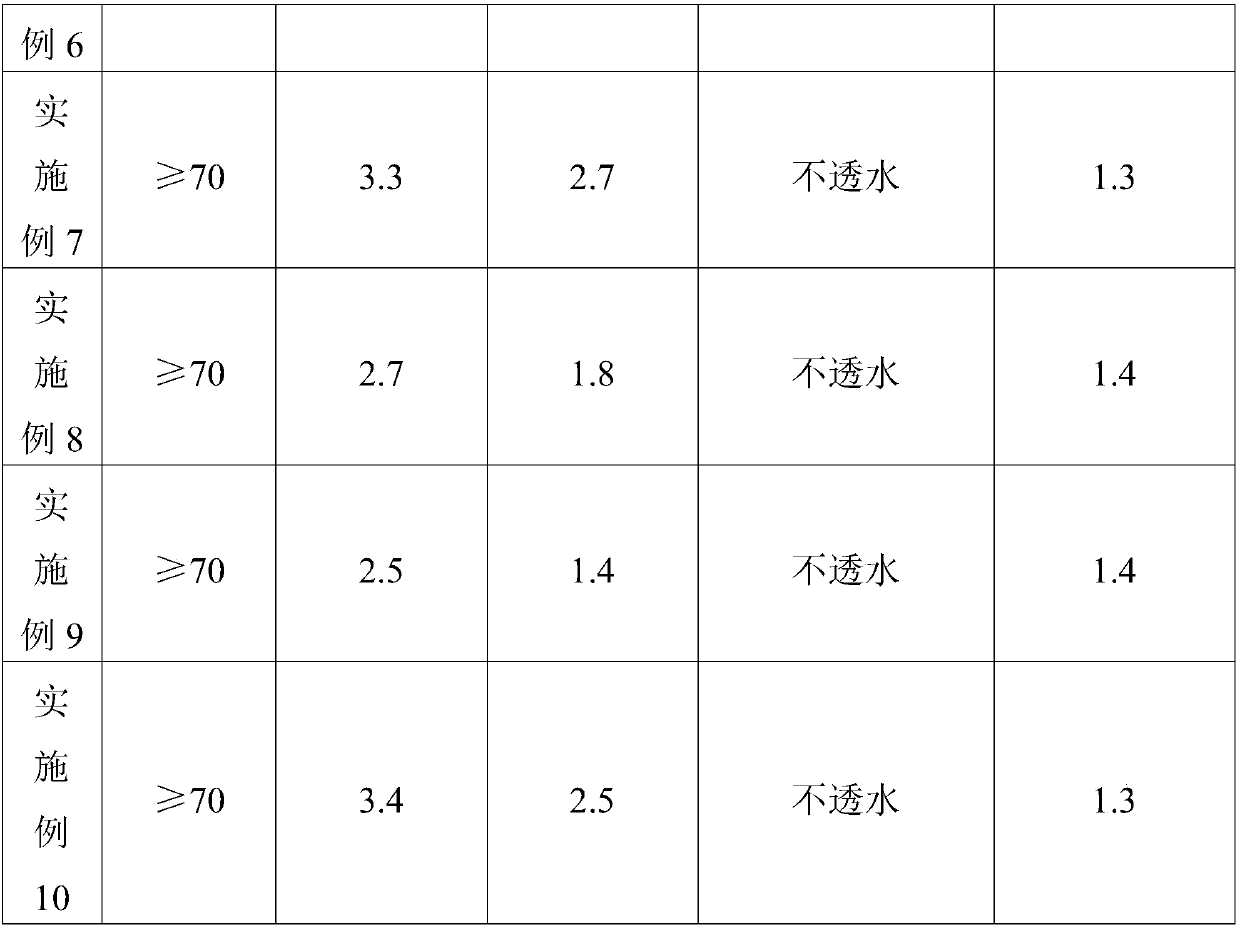

Examples

Embodiment 1

[0074] An anti-seepage and anti-crack waterproof coating with strong cohesive force, which is composed of liquid material and powder material, wherein the mass of the liquid material is 758.1kg, and the mass of the powder material is 1844kg;

[0075] Described liquid material is made up of 600kg polyacrylate emulsion, 150kg water, 3.8kg NXZ defoamer, 0.5kg dibutyl maleate preservative and 3.8kg Dispex AA4140 dispersant;

[0076] The powder is composed of 750kg 42.5 cement, 640kg 100 mesh quartz sand, 450kg 280 mesh quartz sand and 4kg FDN water reducer.

[0077] The preparation method of the liquid material is to add water, emulsion, defoamer, preservative and dispersant in sequence to the container and stir for 1 hour with a liquid high-speed dispersing mixer at 1200 rpm to obtain the product.

[0078] The preparation method of the powder is to add cement and quartz sand into the metering bin and mix evenly, then add the water reducer previously added to the manual feeding bi...

Embodiment 2

[0081] An anti-seepage and anti-crack waterproof coating with strong cohesive force, which is composed of liquid material and powder material, wherein the mass of the liquid material is 758.1kg, and the mass of the powder material is 1844kg;

[0082] The liquid material is composed of 600kg polyacrylate emulsion, 150kg water, 3.8kg NXZ defoamer, 0.5kg inorganic salt / graphene oxide material preservative and 3.8kg Dispex AA4140 dispersant;

[0083] The powder is composed of 750kg 42.5 cement, 640kg 100 mesh quartz sand, 450kg 280 mesh quartz sand and 4kg foam fiber.

[0084] The preparation method of the inorganic salt / graphene oxide is to add 2.5g graphene oxide to 6.25kg water, 300W / 20kHz ultrasonic for 20 minutes, add 500g silver nitrate, 430g zinc nitrate and 89g manganese nitrate, stir at 300rpm for 40 minutes, add 7.36kg of 0.8mol / L disodium hydrogen phosphate aqueous solution, stirred at 300rpm for 45 minutes, passed through a 100-mesh sieve, and dried at 60°C, the obtain...

Embodiment 3

[0090] An anti-seepage and anti-crack waterproof coating with strong cohesive force, which is composed of liquid material and powder material, wherein the mass of the liquid material is 758.1kg, and the mass of the powder material is 1844kg;

[0091] The liquid material is composed of 600kg polyacrylate emulsion, 150kg water, 3.8kg NXZ defoamer, 0.5kg inorganic salt / graphene oxide material preservative and 3.8kg Dispex AA4140 dispersant;

[0092] The powder consists of 750kg 42.5 cement, 1090kg 100 mesh quartz sand and 4kg foam fiber.

[0093] The preparation method of the inorganic salt / graphene oxide is to add 2.5g graphene oxide to 6.25kg water, 300W / 20kHz ultrasonic for 20 minutes, add 500g silver nitrate and 430g zinc nitrate, stir at 300rpm for 40 minutes, add 6.62kg0.8mol / L disodium hydrogen phosphate aqueous solution, stirred at 300rpm for 45 minutes, passed through a 100-mesh sieve, and dried at 60°C, the obtained solid was the inorganic salt / graphene oxide material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com