Concrete pumping agent capable of preventing pipe blockage and water seepage

A concrete pump and pipe plugging technology, which is applied in the field of building materials, can solve problems affecting the quality of concrete projects, threats to physical health, and failure to use normally, and achieve the advantages of convenient industrial production, small negative impact on comprehensive performance, and rapid slump loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

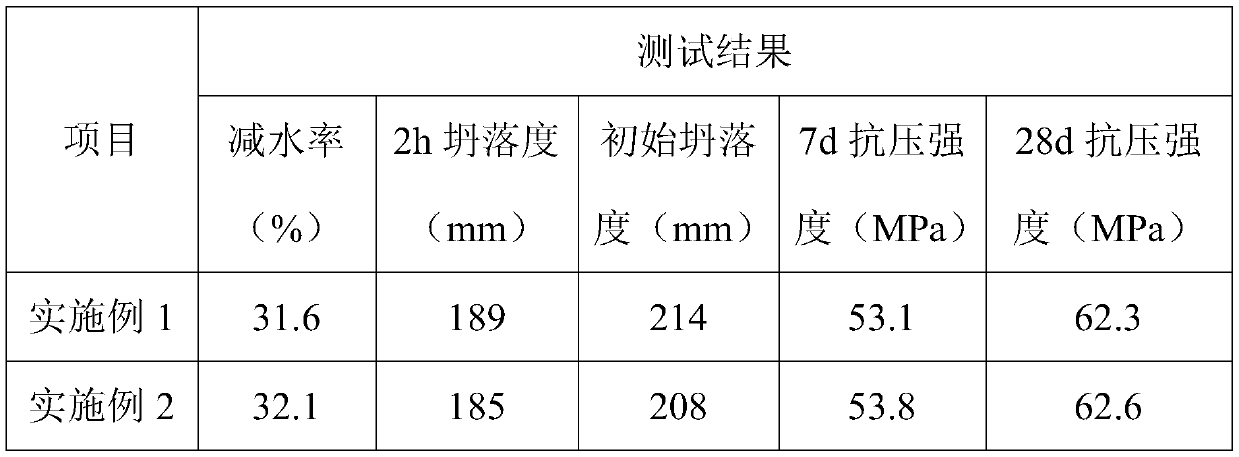

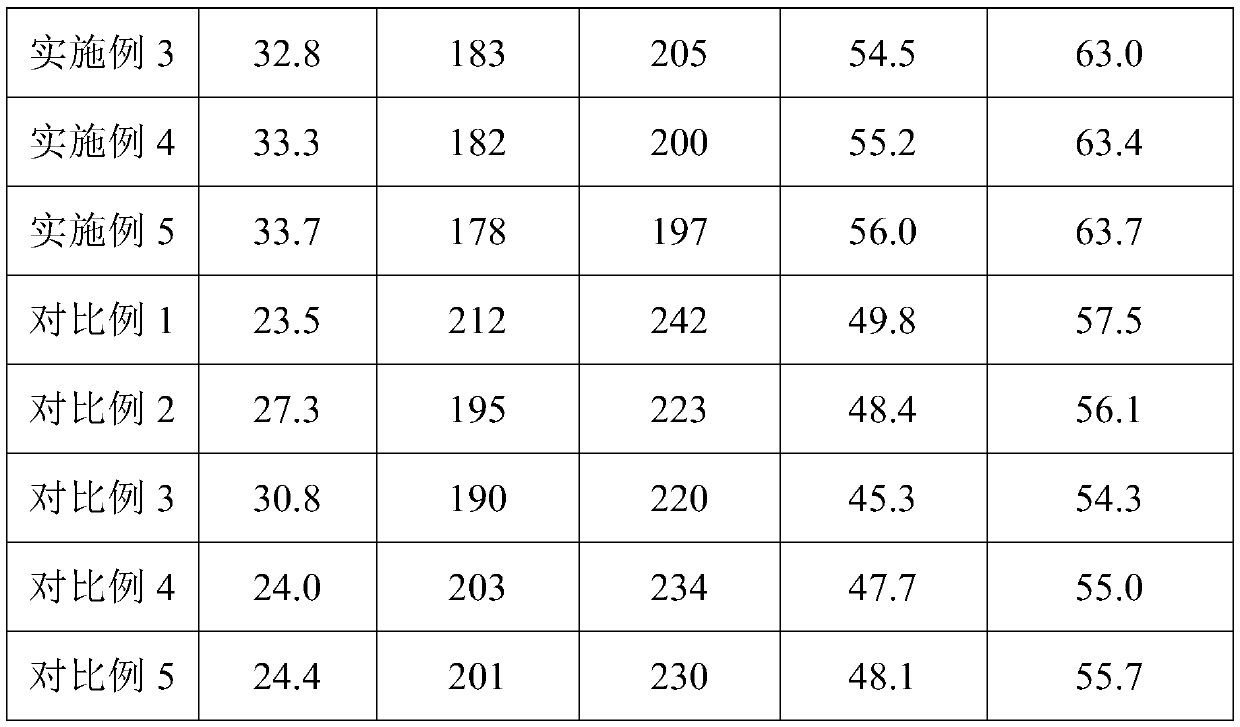

Examples

Embodiment 1

[0025] A concrete pumping agent that does not block pipes and water, is characterized in that it is made of the following components in parts by weight: bis(2-chloroethyl)hydrogen phosphate / piperazine-N,N-bis( 2-Hydroxyethanesulfonic acid) disodium salt condensation polymer 4 parts, hyperbranched polyamino acid 0.2 part, maleimide-tris(ethylene glycol)-propionic acid / triethanolamine oleic acid soap / vinylphosphonic acid 10 parts of copolymer, 2 parts of hydroxapsandite, 0.1 part of carboxymethyl chitosan, 30 parts of water.

[0026]The preparation method of the bis(2-chloroethyl) hydrogen phosphate / piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt condensation polymer comprises the following steps: di(2-chloro Ethyl) hydrogen phosphate and piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt were added to N,N-dimethylformamide, stirred and reacted at 40°C for 5 hours, and then The N,N-dimethylformamide was removed by rotary evaporation to obtain bis(2-ch...

Embodiment 2

[0031] A concrete pumping agent that does not block pipes and water, is characterized in that it is made of the following components in parts by weight: bis(2-chloroethyl)hydrogen phosphate / piperazine-N,N-bis( 2-Hydroxyethanesulfonic acid) disodium salt condensation polymer 5 parts, hyperbranched polyamino acid 0.3 part, maleimide-tris(ethylene glycol)-propionic acid / triethanolamine oleic acid soap / vinylphosphonic acid 11 parts of copolymer, 2.5 parts of hydroxapsandite, 0.15 parts of carboxymethyl chitosan, and 33 parts of water.

[0032] The preparation method of the bis(2-chloroethyl) hydrogen phosphate / piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt condensation polymer comprises the following steps: di(2-chloro Ethyl) hydrogen phosphate and piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt were added to N,N-dimethylacetamide, stirred and reacted at 45°C for 5.5 hours, and then The N,N-dimethylacetamide was removed by rotary evaporation to obta...

Embodiment 3

[0037] A concrete pumping agent that does not block pipes and water, is characterized in that it is made of the following components in parts by weight: bis(2-chloroethyl)hydrogen phosphate / piperazine-N,N-bis( 2-Hydroxyethanesulfonic acid) disodium salt condensation polymer 6 parts, hyperbranched polyamino acid 0.35 parts, maleimide-tris(ethylene glycol)-propionic acid / triethanolamine oleic acid soap / vinylphosphonic acid 13 parts of copolymer, 3 parts of hydroxyazosinite, 0.2 parts of carboxymethyl chitosan, 35 parts of water.

[0038] The preparation method of the bis(2-chloroethyl) hydrogen phosphate / piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt condensation polymer comprises the following steps: di(2-chloro Ethyl) hydrogen phosphate and piperazine-N,N-bis(2-hydroxyethanesulfonic acid) disodium salt were added to tetrahydrofuran, stirred and reacted at 50°C for 6 hours, and tetrahydrofuran was removed by rotary evaporation to obtain di( 2-Chloroethyl) hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com