A kind of high-strength concrete and its preparation process

A concrete, high-strength technology, applied in the direction of organic chemistry, etc., can solve the problems of high-strength concrete shrinkage, cracks, temperature rise of high-strength concrete, etc., achieve high flexural and compressive strength, long service life, and reduce hydration. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

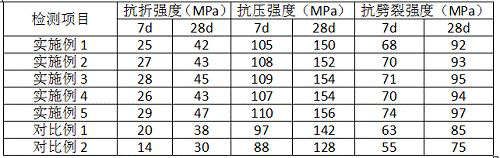

Examples

Embodiment 1

[0027]A high-strength concrete, comprising the following components made of: 80kg of cement, 60kg of coarse aggregate, 70kg of fine aggregate, 5kg of calixpyrrole modified nanoboron fibers, 2,5 kg of bromosuccinic acid ionization modification -Bis(diethylamino)phenyl-1,3,4-oxadiazole 1kg, carboxyl-containing hyperbranched poly(amine-ester) acrylic acid 0.5kg, zeolite powder 5kg, boron carbide ceramic powder 2kg, attapulgite 10kg , Carboxyl-terminated liquid nitrile rubber 1kg, water 40kg.

[0028] The preparation method of the calixpyrrole-modified nano-boron fibers includes the following steps: dispersing the nano-boron fibers in an organic solvent, then adding a silane coupling agent KH560 to it, stirring at 60° C. for 3 hours, and then adding to it Meso-tetramethyl-meso-tetraaminophenylcalix[4]pyrrole and basic catalyst were stirred and reacted at 60°C for 2 hours. After the reaction, the solvent was removed by rotary evaporation to obtain calixpyrrole modified nanoboron fi...

Embodiment 2

[0035] A high-strength concrete, comprising the following components made of: 85kg of cement, 65kg of coarse aggregate, 72kg of fine aggregate, 6kg of calixpyrrole modified nanoboron fibers, 2,5 kg of bromosuccinic acid ionization modification -Bis(diethylamino)phenyl-1,3,4-oxadiazole 1.5kg, carboxyl-containing hyperbranched poly(amine-ester) acrylic acid 0.7kg, zeolite powder 6kg, boron carbide ceramic powder 2.5kg, attapulgite Soil 11kg, carboxyl-terminated liquid nitrile rubber 1.2kg, water 45kg.

[0036] The preparation method of the calixpyrrole-modified nanoboron fiber comprises the following steps: dispersing the nanoboron fiber in an organic solvent, then adding a silane coupling agent KH560 thereto, stirring at 65° C. for 3.5 hours, and then adding to it Meso-tetramethyl-meso-tetraaminophenyl calix[4]pyrrole and basic catalyst were stirred and reacted at 65° C. for 2.5 hours. After the reaction, the solvent was removed by rotary evaporation to obtain calixpyrrole modi...

Embodiment 3

[0043] A high-strength concrete, comprising the components of the following qualities: 90kg of cement, 70kg of coarse aggregate, 75kg of fine aggregate, 6.5kg of calixpyrrole-modified nano-boron fibers, and ionized modified bromosuccinic acid 2, 5-bis(diethylamino)phenyl-1,3,4-oxadiazole 2kg, carboxyl-containing hyperbranched poly(amine-ester) acrylic acid 0.8kg, zeolite powder 6.5kg, boron carbide ceramic powder 3kg, attapulgite Soil 13kg, carboxyl-terminated liquid nitrile rubber 1.5kg, water 50kg.

[0044] The preparation method of the calixpyrrole-modified nano-boron fiber includes the following steps: dispersing the nano-boron fiber in an organic solvent, then adding a silane coupling agent KH560 to it, stirring at 70° C. for 4 hours, and then adding to it Meso-tetramethyl-meso-tetraaminophenylcalix[4]pyrrole and basic catalyst were stirred and reacted at 70°C for 3 hours. After the reaction, the solvent was removed by rotary evaporation to obtain calixpyrrole modified na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com