Environment-friendly concrete pumping agent and preparation method thereof

An environmentally friendly concrete and pumping agent technology, applied in the field of concrete additives, can solve the problems of rapid concrete slump loss, poor fluidity, rapid slump loss, etc., and achieves easy industrial production, good water-reducing and retarding performance. , the effect of controlling slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

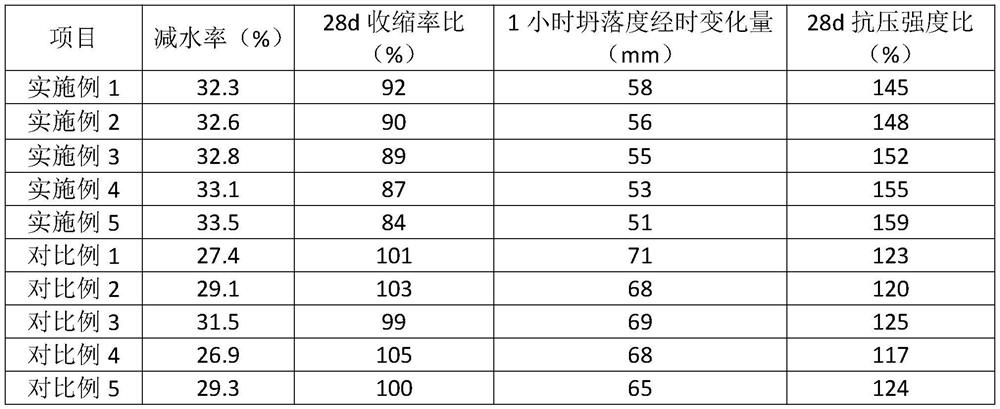

Examples

Embodiment 1

[0029] An environmentally friendly concrete pumping agent, characterized in that it comprises the following components in parts by weight: 8 parts of sulfobutyl-β-cyclodextrin sodium, 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano 4 parts of hybrid polymer, 3 parts of rosin-based hyperbranched polyester, 10 parts of polycarboxylate high-performance water reducer, 0.1 part of defoamer, and 45 parts of water.

[0030] Described defoamer is German AGITAN powder defoamer P803.

[0031] The polycarboxylate high-performance water reducer is KH-D1-X polycarboxylate high-performance water reducer, purchased from Wuhan Huaxuan High-Tech Co., Ltd.

[0032] The preparation method of the 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano-hybrid polymer comprises the following steps: adding 2-chloroethylsulfonate sodium and hydroxyl-terminated hyperbranched nano-hybrid polymer to In a high-boiling point solvent, stir and react at 4...

Embodiment 2

[0037] An environmentally friendly concrete pumping agent, characterized in that it includes the following components in parts by weight: 9 parts of sulfobutyl-β-cyclodextrin sodium, 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano 5 parts of hybrid polymer, 3.5 parts of rosin-based hyperbranched polyester, 12 parts of polycarboxylate high-performance water reducer, 0.15 parts of defoamer, and 50 parts of water.

[0038] Described defoamer is German AGITAN powder defoamer P803.

[0039] The polycarboxylate high-performance water reducer is KH-D1-X polycarboxylate high-performance water reducer, purchased from Wuhan Huaxuan High-Tech Co., Ltd.

[0040] The preparation method of the 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano-hybrid polymer comprises the following steps: adding 2-chloroethylsulfonate sodium and hydroxyl-terminated hyperbranched nano-hybrid polymer to In a high-boiling point solvent, stir and react a...

Embodiment 3

[0045] An environmentally friendly concrete pumping agent is characterized in that it includes the following components in parts by weight: 11 parts of sulfobutyl-β-cyclodextrin sodium, 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano 5.5 parts of hybrid polymer, 4 parts of rosin-based hyperbranched polyester, 13 parts of polycarboxylate high-performance water reducer, 0.2 part of defoamer, and 55 parts of water.

[0046] Described defoamer is German AGITAN powder defoamer P803.

[0047] The polycarboxylate high-performance water reducer is KH-D1-X polycarboxylate high-performance water reducer, purchased from Wuhan Huaxuan High-Tech Co., Ltd.

[0048] The preparation method of the 2-chloroethylsulfonate sodium modified hydroxyl-terminated hyperbranched nano-hybrid polymer comprises the following steps: adding 2-chloroethylsulfonate sodium and hydroxyl-terminated hyperbranched nano-hybrid polymer to In a high-boiling point solvent, stir and react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com