Cement-based self-leveling dry powder mortar for high-cracking-resistance ground

A dry powder mortar and cement-based technology, which is applied in the field of building materials, can solve the problems of poor water resistance, high cost, and corrosion of iron products, and achieve the effect of cost reduction and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Embodiment 1: A kind of cement-based self-leveling dry powder mortar for high anti-cracking ground is composed of cement, fine sand, heavy calcium powder, lithium slag powder, expansion agent, coagulation regulator, superplasticizer, defoamer, anti-cracking agent Fiber composition, the specific raw material composition ratio is calculated in parts by weight: 300 parts of 42.5R ordinary Portland cement, 550 parts of fine sand of 20-150 mesh aeolian sand, 30 parts of heavy calcium powder, of which CaCO 3 Content ≥ 95%, fineness specification is specific surface area 300 ~ 400m 2 / kg, 90 parts of lithium slag powder, the fineness specification is specific surface area ≥ 300m 2 / kg, 20 parts of commercially available calcium sulfate (AEA) expansion agents, 1.5 parts of lithium carbonate as coagulation regulator, 5 parts of casein as superplasticizer, and 5 parts of casein as commercially available P803 powdered defoamer produced by Mingling Chemical in Germany. 2 parts, ant...

Embodiment 2

[0039] Embodiment 2: A kind of cement-based self-leveling dry powder mortar for high anti-cracking ground is composed of cement, fine sand, heavy calcium powder, lithium slag powder, expansion agent, coagulation regulator, superplasticizer, defoamer, anti-cracking agent Fiber composition, the specific raw material composition ratio is calculated in parts by weight: 300 parts of 42.5R ordinary Portland cement, 500 parts of fine sand of 20-150 mesh aeolian sand, 100 parts of heavy calcium powder, of which CaCO 3 Content ≥ 95%, fineness specification is specific surface area 300 ~ 400m 2 / kg, 60 parts of lithium slag powder, the fineness specification is specific surface area ≥ 300m 2 / kg, 30 parts of commercially available calcium sulfoaluminate (UEA) expansion agent, 7 parts of calcium formate as coagulation regulator, 3 parts of polycarboxylate powder as superplasticizer, commercially available P803 powder produced by Mingling Chemical in Germany The anti-cracking fiber is 1 ...

Embodiment 3

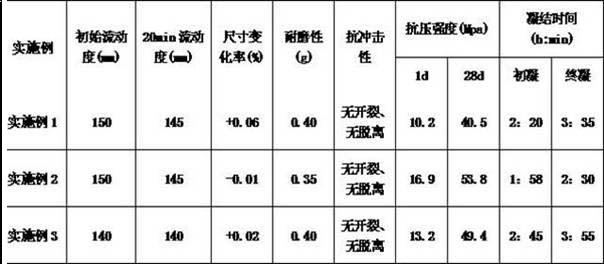

[0041] Table 1 Performance test results of cement-based self-leveling dry powder mortar for high-crack-resistant ground obtained in the examples

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com