High-corrosion-resistance ocean engineering material and preparation method thereof

A technology for marine engineering and raw materials, applied in the field of high corrosion-resistant marine engineering materials and their preparation, can solve problems such as poor stability, paint corrosion, seawater corrosion, etc., to improve strength and durability, improve dispersion efficiency, and microstructure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

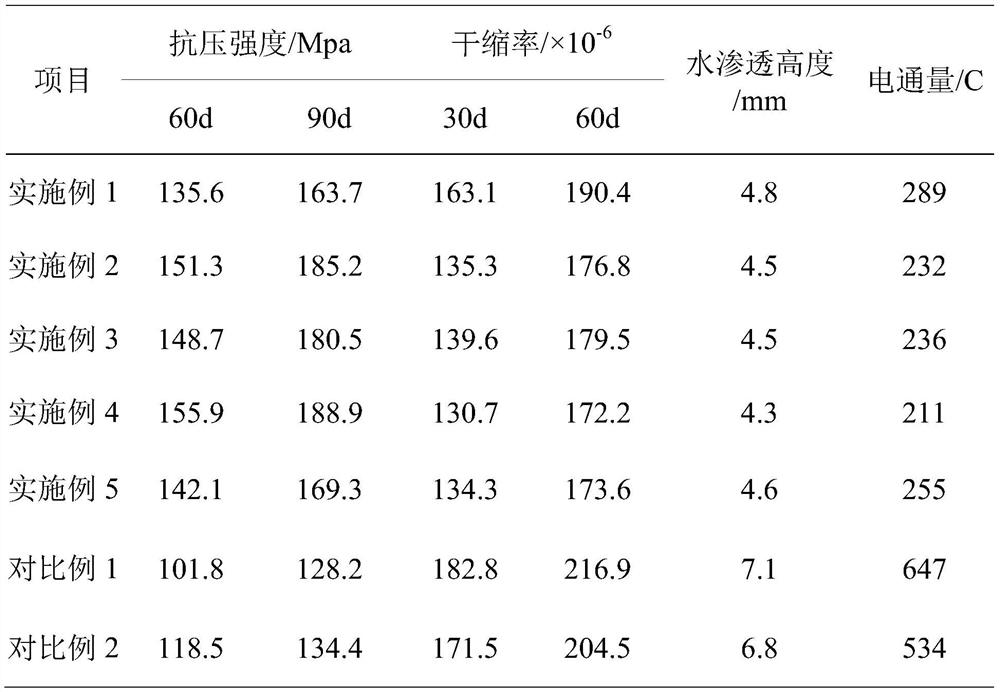

Examples

Embodiment 1

[0022] A high-corrosion marine engineering material, comprising the following raw materials in parts by weight: 40 parts of Portland cement, 5 parts of silica fume, 1 part of nano-silicon, 1 part of superplasticizer, 5 parts of densifying agent, 0.01 part of defoaming agent and 30 parts of fine aggregate;

[0023] Among them, nano-silicon is mixed by gas phase nano-silica and precipitated nano-silica with a mass ratio of 0.5:1.2; the superplasticizer is polycarboxylate water reducer; the densifying agent is vinyl acetate and Acrylate and fatty acid vinyl ester tripartite copolymer; defoamer is alkoxy modified fatty alcohol defoamer; fine aggregate is made of quartz sand and natural river sand with a mass ratio of 0.6:1.1, and the natural river sand The particle size is 30-100 mesh, including 30% of 30-50 mesh, 45% of 50-80 mesh, and 25% of 80-100 mesh.

[0024] The preparation method of the marine engineering material is as follows: at a stirring speed of 200rpm, mix portland...

Embodiment 2

[0026] A high-corrosion marine engineering material, comprising the following raw materials in parts by weight: 60 parts of Portland cement, 10 parts of silica fume, 3 parts of nano silicon, 2.5 parts of superplasticizer, 10 parts of compacting agent, 0.03 parts of defoaming agent and 50 parts of fine aggregate;

[0027] Among them, nano-silicon is formed by mixing gas-phase nano-silica and precipitated nano-silica with a mass ratio of 0.8:1.5, and the particle size of gas-phase nano-silica is 20nm, and the particle size of precipitated nano-silica is 10nm.

[0028] The superplasticizer is a mixture of polyethylene glycol polycondensate and modified sulfonated melamine polycondensate with a mass ratio of 1:1.

[0029] The compacting agent is a tripartite copolymer of ethylene, vinyl chloride and vinyl laurate.

[0030] The defoamer is alkane hydrocarbon modified fatty alcohol defoamer.

[0031] The fine aggregate is made by mixing quartz sand and natural river sand with a m...

Embodiment 3

[0033] A high-corrosion marine engineering material, comprising the following raw materials in parts by weight: 50 parts of Portland cement, 6 parts of silica fume, 2 parts of nano silicon, 1.5 parts of superplasticizer, 8 parts of densifying agent, 0.02 parts of defoaming agent and 40 parts of fine aggregate.

[0034] Among them, nano-silicon is formed by mixing gas-phase nano-silica and precipitated nano-silica with a mass ratio of 0.6:1.35. The particle size of gas-phase nano-silica is 10nm, and the particle size of precipitated nano-silica is 15nm.

[0035] The superplasticizer is a mixture of polyethylene glycol polycondensate and modified sulfonated melamine polycondensate with a mass ratio of 1:3.

[0036] The compacting agent is a tripartite copolymer of vinyl acetate, acrylate and fatty acid vinyl ester.

[0037] The defoamer is a silane-modified fatty alcohol defoamer.

[0038] The fine aggregate is made by mixing quartz sand and natural river sand with a mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com