Recycled concrete

A technology for recycled concrete and recycled aggregate, applied in the field of recycled concrete, can solve the problems of affecting workability, strong water absorption, and reduced strength, and achieve the effects of reducing dry shrinkage, enhancing adsorption, and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

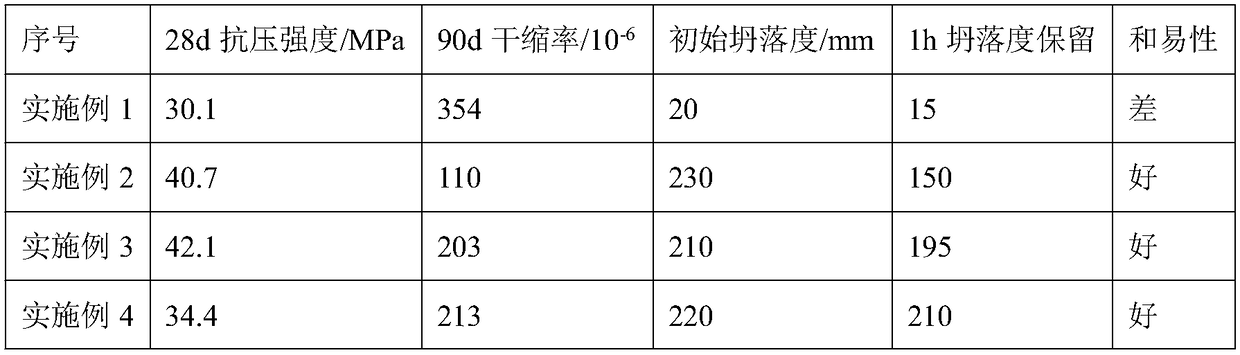

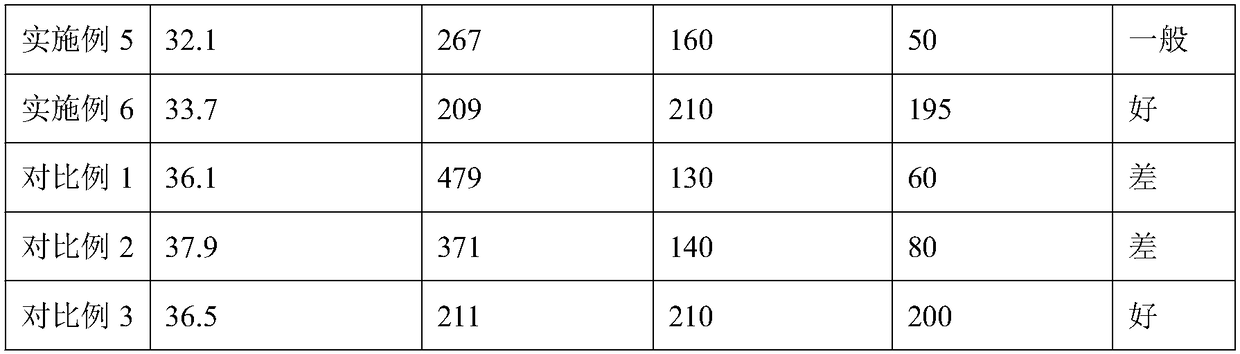

Examples

Embodiment 1

[0023] A recycled concrete, which is composed of the following raw materials in parts by weight: 230 parts of cement, 1300 parts of recycled aggregate, 200 parts of ferronickel slag, 80 parts of superfine admixture, 2 parts of water reducer, 0.5 part of retarder, 0.5 parts of shrinkage reducing agent, 0.1 part of reinforcing agent, 0.05 parts of air-entraining agent, and 108.5 parts of water.

[0024] The superfine admixture is ceramic tile polishing powder.

[0025] The retarder is composed of aminotrimethylene phosphonic acid, glycerol and sorbic acid in a weight ratio of 2:1:1.

[0026] The shrinkage reducing agent is dipropyl ethylene glycol monobutyl ether.

[0027] The enhancer is composed of sodium sulfite, diethanol monoisopropanolamine and tetramethylammonium hydroxide in a weight ratio of 5:5:1.

Embodiment 2

[0029] A recycled concrete, which is composed of the following raw materials in parts by weight: 330 parts of cement, 800 parts of recycled aggregate, 400 parts of ferronickel slag, 30 parts of superfine admixture, 5 parts of water reducing agent, 0.01 part of retarder, 3 parts of shrinkage reducing agent, 1 part of reinforcing agent, 0.01 part of air-entraining agent, and 126 parts of water.

[0030] The ultra-fine admixture is silicon carbide waste.

[0031] The retarder is composed of aminotrimethylene phosphonic acid, glycerol and sorbic acid in a weight ratio of 1:5:1.

[0032] The shrinkage reducing agent is dipropyl glycol.

[0033] The reinforcing agent is composed of sodium sulfite, diethanol monoisopropanolamine and tetramethylammonium hydroxide in a weight ratio of 10:1:1.

Embodiment 3

[0036] A recycled concrete, which is composed of the following raw materials in parts by weight: 300 parts of cement, 1100 parts of recycled aggregate, 300 parts of ferronickel slag, 50 parts of silicon carbide waste, 3 parts of water reducer, 0.1 part of retarder, shrinkage reducer 0.8 parts, 0.5 parts of reinforcing agent, 0.03 parts of air-entraining agent, and 122.5 parts of water.

[0037] The silicon carbide waste is subjected to the following treatment process: high-temperature calcination at 450°C for 2 hours, and then ground to a specific surface area of 620m after reaching room temperature 2 / kg.

[0038] The retarder is composed of aminotrimethylene phosphonic acid, glycerol and sorbic acid in a weight ratio of 1:1:1.

[0039] The shrinkage reducing agent is dipropyl ethylene glycol monobutyl ether.

[0040] The reinforcing agent is composed of sodium sulfite, diethanol monoisopropanolamine and tetramethylammonium hydroxide in a weight ratio of 6:3:1.

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com