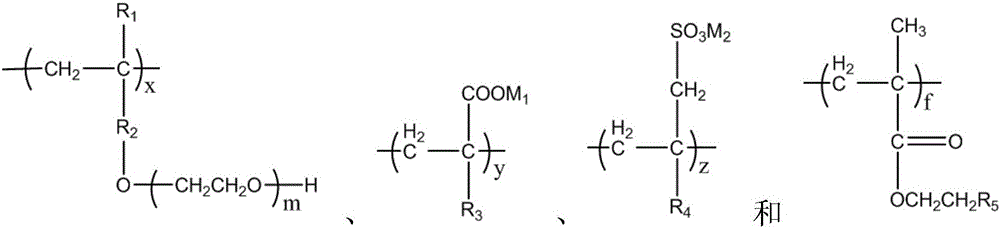

Early-strength polycarboxylate water reducing agent and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent, can solve the problems of restricting use and affecting development, and achieve the effect of good flow dispersion and high water reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

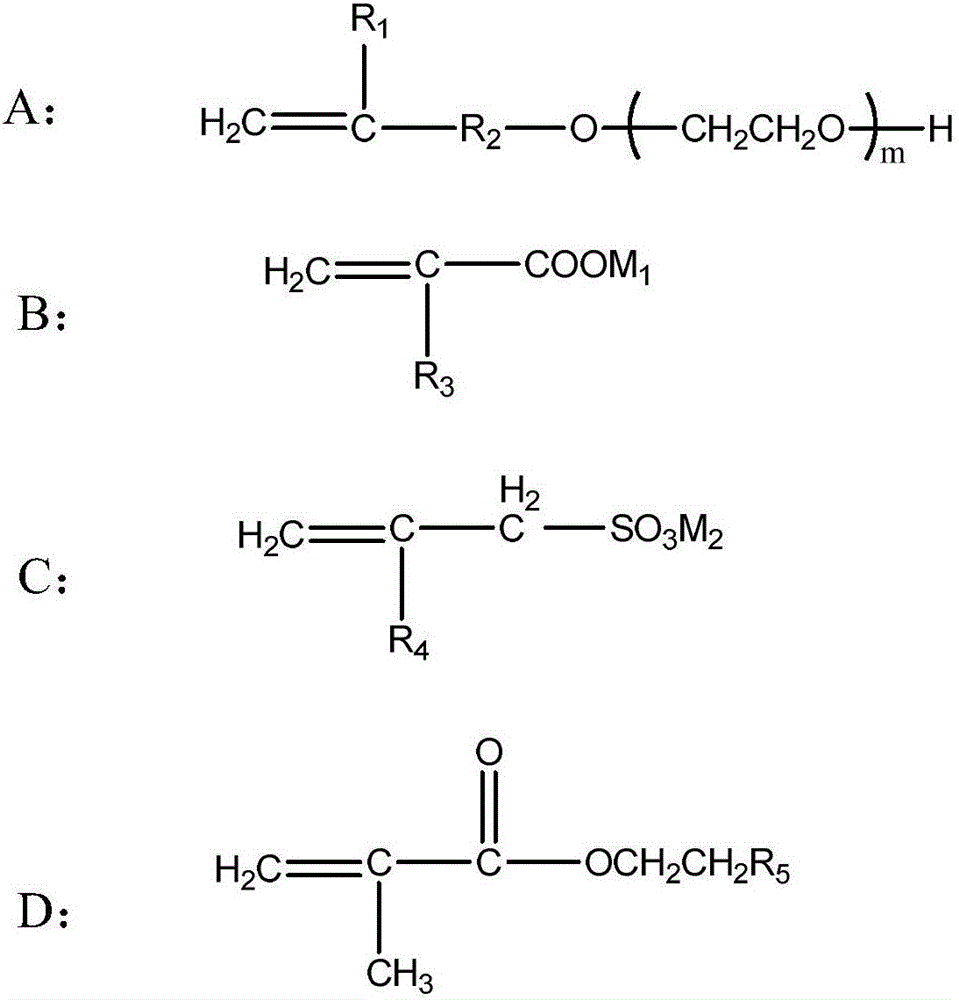

Method used

Image

Examples

preparation example Construction

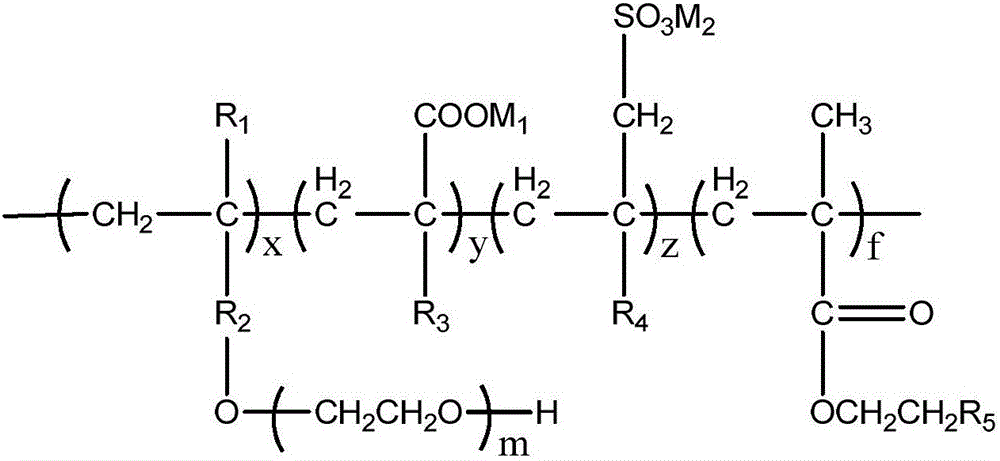

[0042] In one embodiment of the present invention, the preparation method of early-strength polycarboxylate superplasticizer may specifically include:

[0043] Put the monomer A and deionized water into the reactor, stir until the monomer A is completely dissolved, and slowly raise the temperature to the reaction temperature of 20-40°C, add the oxidant at one time, and drop it into the reactor at the same time after 5-10 minutes Add the aqueous solution made of monomers B and C and the aqueous solution made of monomer D, reducing agent and chain transfer agent; the former is finished dripping in 2.5-3 hours, and the latter is dripped in 3-3.5 hours; after both are completely dripped, continue After stirring for 1-2 hours, the temperature is lowered to normal temperature, and the pH of the system is adjusted to 6.5-7.5 with 30wt% NaOH solution to obtain an early-strength polycarboxylate superplasticizer.

[0044] The preparation method of the early-strength polycarboxylate wate...

Embodiment 1

[0048] 150g of methallyl polyoxyethylene ether (M=3000, the average number of moles of ethoxy groups m=65) and 130g of deionized water were thrown into the reactor, stirred until completely dissolved, and then added to the reactor at one time 0.95g H 2 o 2 (30wt% aqueous solution), after 5-10min, simultaneously in the reactor, dropwise add the solution that 16.56g acrylic acid, 3.95g sodium methacrylate and 30g deionized water mix and 2.35g methacrylic acid-2-(di Methylamino) ethyl ester, 0.67g mercaptopropionic acid, 0.75g Vc and 47g deionized water mixed solution; the former 3h drop, the latter 3.5h drop. After all the drops are finished, continue to stir for 1 hour, and finally lower the temperature in the reactor to normal temperature, adjust the pH to 6.5-7.5 with 30% NaOH solution, and replenish water until the solid content is 40wt%, that is, high water-reducing early-strength polymer Carboxylic acid water reducer, its weight average molecular weight measured by multi...

Embodiment 2

[0050] 150g of methallyl polyoxyethylene ether (M=4000, the average number of moles of ethoxy group m=90) and 130g of deionized water were thrown into the reactor, stirred until completely dissolved, and then added to the reactor at one time 1.25g H 2 o 2 (30wt% aqueous solution), after 5-10min, simultaneously dropwise add 14.51g methacrylic acid, 3.24g allyl sodium sulfonate and 30g deionized water mixed solution and 1.39g methacrylic acid-2- (Diethylamino) ethyl ester, 1.12g of mercaptopropionic acid, 0.92g of Vc and 45g of deionized water mixed solution; the former 3h drop, the latter 3.5h drop. After all the drops are finished, continue to stir for 1 hour, and finally lower the temperature in the reactor to normal temperature, adjust the pH to 6.5-7.5 with 30% NaOH solution, and replenish water until the solid content is 40wt%, that is, high water-reducing early-strength polymer Carboxylic acid water reducer, its weight average molecular weight measured by multi-angle la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com