Hollow microsphere composite modified thermosetting polyimide material and preparation method thereof

A technology of polyimide and hollow microspheres, which is applied in the field of hollow microsphere composite modified thermosetting polyimide materials and its preparation, can solve the problems of difficult melting, difficult dissolution and low use temperature, and achieve outstanding performance, Special structure, reduce tangle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

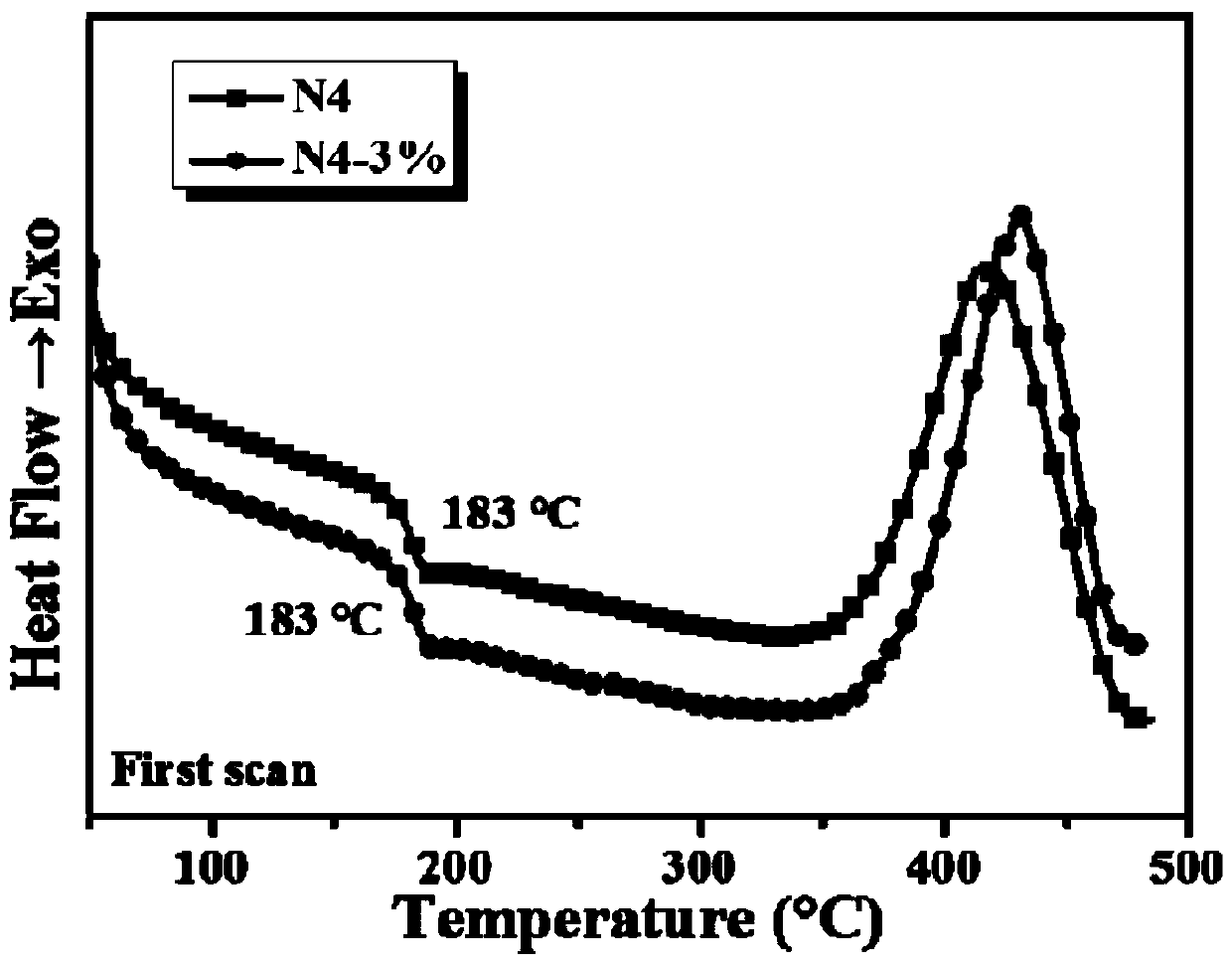

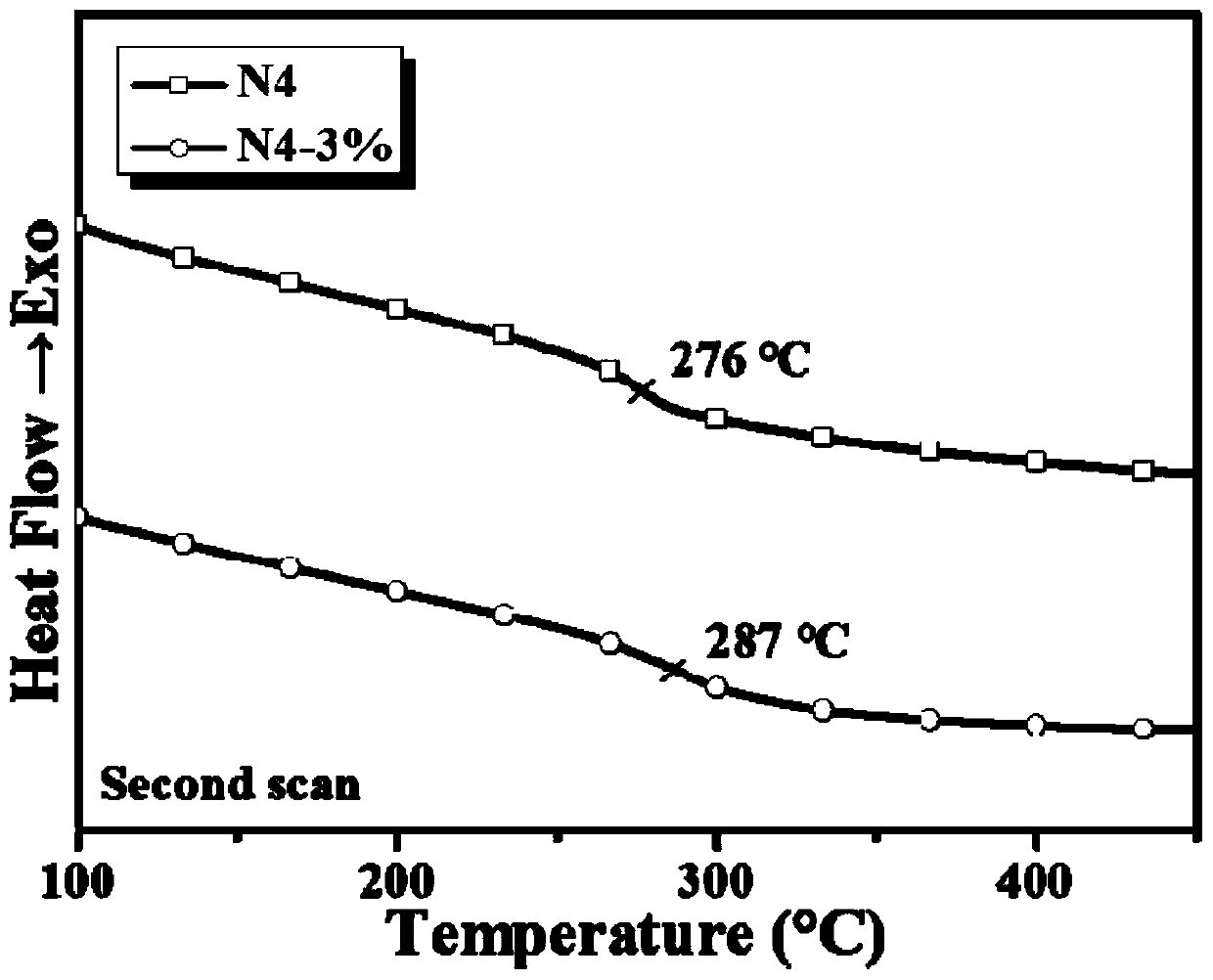

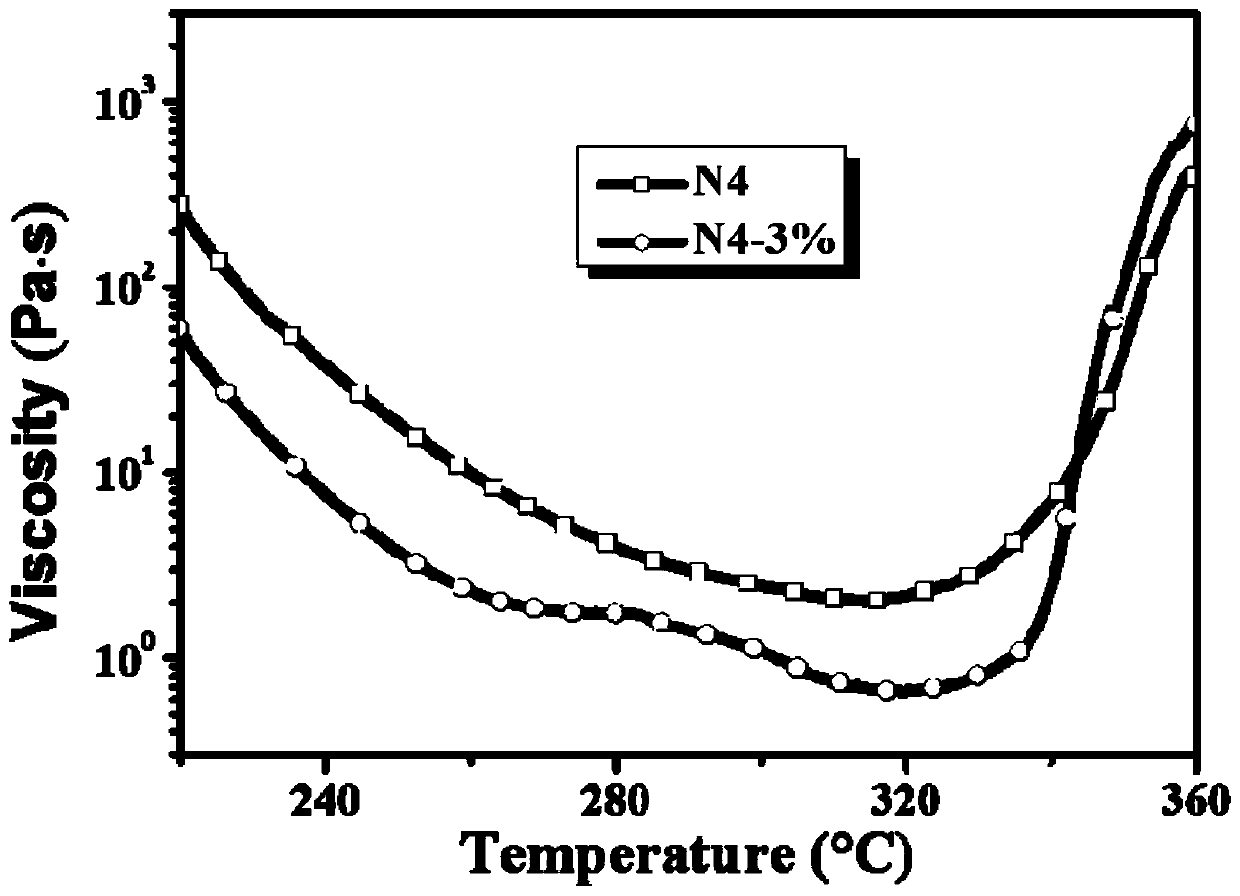

[0034] First use a beaker to make a solution of 3-aminopropyltriethoxysilane (KH550) coupling agent with a mass fraction of 2% hollow microspheres and absolute ethanol (100mL absolute ethanol per 0.3g KH550), and then add the particle size Hollow microspheres of about 20um were fully impregnated and stirred for 5 hours, and finally filtered with suction, fully dried in a vacuum oven at 100°C to constant weight, and then sieved for later use. Use monomers 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA), 3,4'-diaminodiphenyl ether (3,4'-ODA) and phenylacetylene phthalic anhydride (PEPA) ) to synthesize and prepare a thermosetting polyimide prepolymer (N4) with a degree of polymerization of 4, and then add the prepared active hollow microspheres to the prepolymer N4 at a mass fraction of 3%, and use a torque rheometer in Melt and mix at a high temperature of 270° C. for 20 minutes and then take out to finally obtain a hollow microsphere / thermosetting polyimide compo...

Embodiment 2

[0038] First use the monomer 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA), 3,4'-diaminodiphenyl ether (3,4'-ODA) and phenylacetylene phthalic anhydride ( PEPA) synthetically prepares the thermosetting polyimide prepolymer (N4) that the degree of polymerization is 4, and then the hollow microspheres with a particle size of about 20um after sieving and drying are treated with a coupling agent with a mass of 3%. Fractions were added to the prepolymer N4, and the torque rheometer was used to carry out melt mixing at a high temperature of 270°C for 20 minutes and then taken out to finally obtain hollow microspheres / thermosetting polyimide composite materials.

Embodiment 3

[0040] First use a beaker to make a solution of 3-aminopropyltriethoxysilane (KH550) coupling agent with a mass fraction of 2% hollow microspheres and absolute ethanol (100mL absolute ethanol per 0.3g KH550), and then add the particle size Hollow microspheres with a diameter of about 100 nm were fully impregnated and stirred for 5 hours, and finally filtered with suction, fully dried in a vacuum oven at 100°C to constant weight, and then sieved before use. Use monomers 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA), 3,4'-diaminodiphenyl ether (3,4'-ODA) and phenylacetylene phthalic anhydride (PEPA) ) to synthesize and prepare a thermosetting polyimide prepolymer (N4) with a degree of polymerization of 4, and then add the prepared active hollow microspheres to the prepolymer N4 at a mass fraction of 3%, and use a torque rheometer in Melt and mix at a high temperature of 270° C. for 20 minutes and then take out to finally obtain a hollow microsphere / thermosetting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com