Recycled pavement paving board and manufacturing technology thereof

A technology for reclaiming pavement and manufacturing process, applied in the field of pavement pavement, can solve the problems of low strength, waste, rough surface, etc., and achieve the effects of improving impact toughness and adhesion, reducing production cost, and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: Regenerated pavement pavement, including base and surface layer, and the components and corresponding parts by weight included in base layer and surface layer are as shown in Table 1, in the admixture adopted in base layer and surface layer The components and their corresponding parts by weight are shown in Table 2, and the recycled pavement pavement board is prepared through the following steps:

[0073] S1, fully mix water, polycarboxylate superplasticizer, citric acid, sodium gluconate, triethanolamine, and potassium sulfate to obtain the first mixture;

[0074] S2, adding the cellulose ether and the thickener to the first mixture obtained in step S1, and fully mixing to obtain the admixture;

[0075] S3, uniformly mix cement, fly ash (first-class fly ash), regenerated sand, regenerated coarse aggregate, and regenerated micropowder to form a second mixture, then add admixtures and water, and fully mix to obtain a base layer mixture;

[0076] S4, fully ...

Embodiment 2-5

[0080] Embodiment 2-5: Regenerated pavement board, the difference with embodiment 1 is that the components and the corresponding parts by weight thereof included in the base layer and the surface layer (except additives) are as shown in Table 1, the base layer and the surface layer The components in the additives used in the layer and their corresponding parts by weight are shown in Table 2.

[0081] In table 1 embodiment 1-5, face layer and basic layer (except admixture) comprise components and parts by weight thereof

[0082]

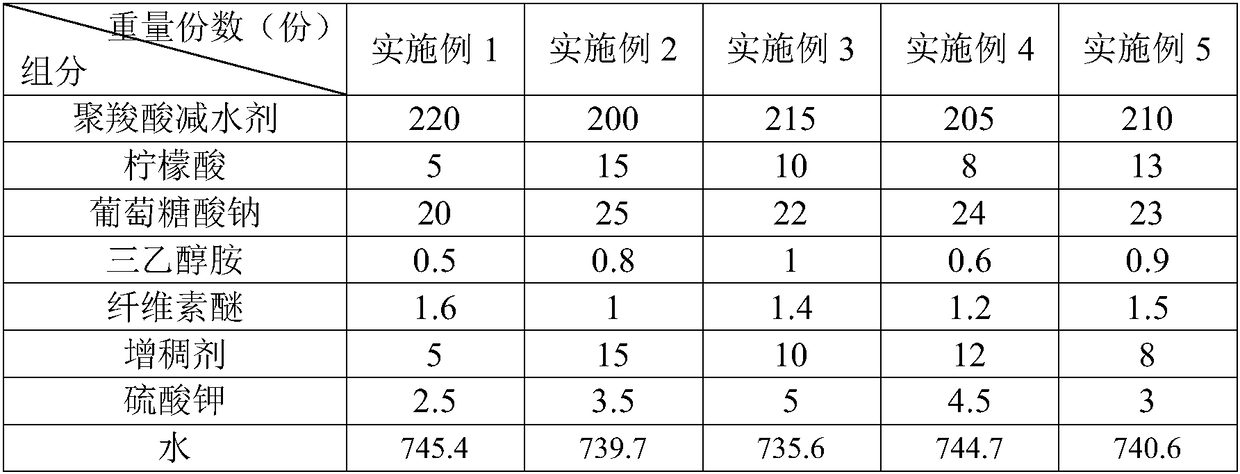

[0083] Components and parts by weight of the admixture in the surface layer and the base layer in the table 2 embodiment 1-5

[0084]

Embodiment 6

[0085] Embodiment 6: Regenerated pavement board, the difference from Embodiment 1 is that the modified resin is polyvinyl acetal modified phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com