Down jacket deodorant containing marine biological components

A technology for marine organisms and down jackets, which is applied in biochemical fiber treatment, textile and papermaking, fiber treatment, etc. It can solve the problems of down damage and unsatisfactory effects, and achieve the effects of promoting stable release, good deodorization effect, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

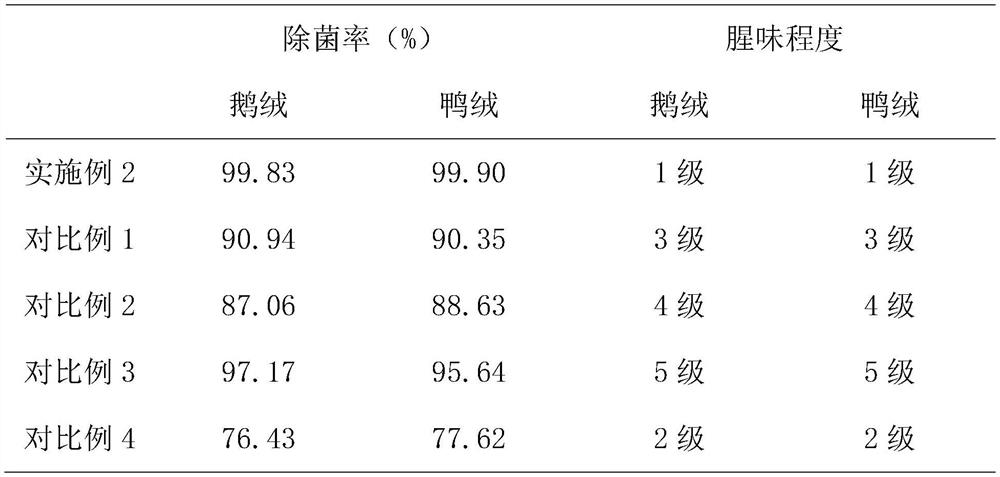

Examples

Embodiment 1

[0023] A down jacket deodorant containing marine biological components, the preparation raw materials of the down jacket deodorant include in parts by weight: 1 part of marine active agent, 4 parts of plant active agent, 20 parts of organic solvent, 0.1 part of aromatic agent and 0.5 part of Part conditioning agent, wherein, the marine active agent is seaweed polysaccharide and chitosan, and the mass ratio is 10:1, and the plant active agent is mixed by coumarin and lignan in the mass ratio of 5:1; The organic solvent is ethanol; the aromatic agent is lavender essential oil through high magnetization treatment (the magnetic field strength is 8000GS, and the treatment time is 80min); the conditioning agent is linoleic acid.

[0024] The preparation method of described down jacket deodorant is:

[0025] (1) Mix coumarin and lignans in proportion, add them to an organic solvent, stir and extract at a temperature of 35° C. at a speed of 300 r / min for 7 hours, and filter to obtain ...

Embodiment 2

[0028] A down jacket deodorant containing marine biological components, the preparation raw materials of the down jacket deodorant include in parts by weight: 3 parts of marine active agents, 7 parts of plant active agents, 35 parts of organic solvents, 0.5 parts of aromatic agents and 1.5 parts of Part conditioning agent, wherein, the marine active agent is seaweed polysaccharide and chitosan, and the mass ratio is 10:3, and the plant active agent is mixed by coumarin and lignan in the mass ratio of 5:1.5; The organic solvent is ethyl acetate; the aromatic agent is peppermint essential oil through high magnetization treatment (the magnetic field strength is 15000GS, and the treatment time is 50min); the conditioning agent is ethylene glycol.

[0029] The preparation method of described down jacket deodorant is:

[0030] (1) Mix coumarin and lignans in proportion, add them to an organic solvent, stir and extract at a temperature of 45° C. at a speed of 400 r / min for 6 hours, a...

Embodiment 3

[0033] A down jacket deodorant containing marine biological components, the preparation raw materials of the down jacket deodorant include in parts by weight: 5 parts of marine active agents, 10 parts of plant active agents, 50 parts of organic solvents, 1 part of fragrance and 3 parts by weight. Part conditioning agent, wherein, the marine active agent is seaweed polysaccharide and chitosan, and the mass ratio is 10:5, and the plant active agent is mixed by coumarin and lignan in the mass ratio of 5:2; The organic solvent is ether; the aromatic agent is lily essential oil that has undergone high magnetization treatment (the magnetic field strength is 20000GS, and the treatment time is 20min); the conditioning agent is amino silicone oil.

[0034] The preparation method of described down jacket deodorant is:

[0035] (1) Mix coumarin and lignans in proportion, add them to an organic solvent, stir and extract at a temperature of 55° C. at a speed of 500 r / min for 5 hours, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com