Degradable antibacterial functional master batch special for polylactic acid and preparation method of degradable antibacterial functional master batch

A technology of functional masterbatch and polylactic acid, which is applied in the field of plastic modification processing, can solve the problems of affecting the antibacterial performance of products, uneven dispersion of raw materials, and environmental pollution caused by dust, so as to shorten the processing molding cycle, excellent flow dispersion, and improve antibacterial properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

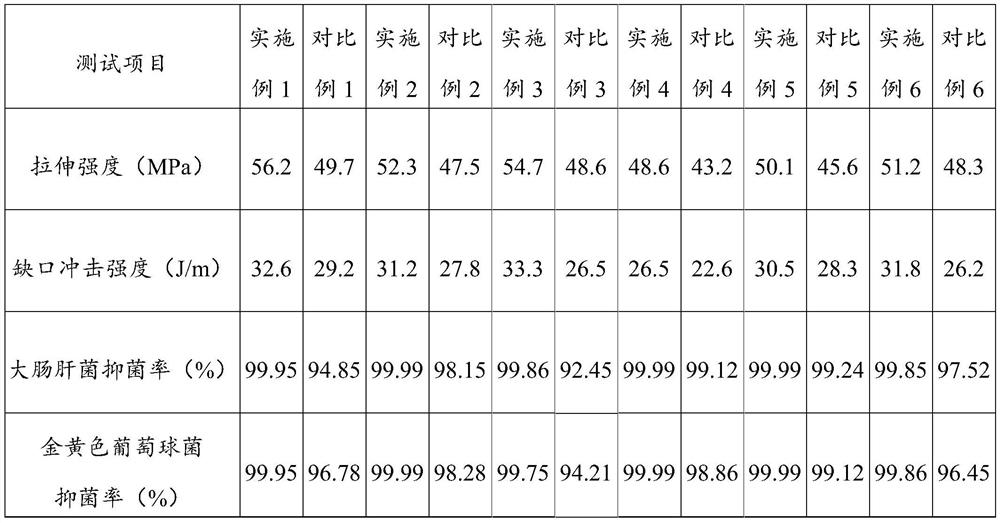

Examples

Embodiment 1

[0031] This embodiment provides a special degradable antibacterial functional masterbatch for polylactic acid, the mass ratio of its components is as follows: 85.0kg low molecular weight polylactic acid; 10.0kg glass / zeolite carrier silver zinc ion antibacterial ); 3.0kg nano-cerium dioxide; 1.0kg mesoporous zirconium hydrogen phosphate; 0.1kg anti-thermal oxygen aging additive; 2.9kg calcium stearate. Among them, the anti-thermal and oxidative aging additive is a compound composed of antioxidant 245 and antioxidant 626 in a mass ratio of 1:1.

[0032] This embodiment also provides a preparation method for the above-mentioned antibacterial functional masterbatch, which specifically includes the following steps:

[0033] Weigh low molecular weight polylactic acid, silver zinc ion antibacterial agent of glass / zeolite carrier, nano ceria, mesoporous zirconium hydrogen phosphate, anti-thermal oxygen aging additive and calcium stearate according to the proportion, and put them into...

Embodiment 2

[0035] This embodiment provides a special degradable antibacterial functional masterbatch for polylactic acid, the mass ratio of its components is as follows: 75.0kg low molecular weight polylactic acid; 18.0kg glass carrier silver ion antibacterial agent (Bactekiller BM-502FA); 1.0 kg nanometer cerium oxide; 3.0kg mesoporous zirconium hydrogen phosphate; 0.3kg anti-thermal oxygen aging additive; 2.7kg zinc stearate. Among them, the anti-thermal and oxidative aging additive is a compound composed of antioxidant 245 and antioxidant 626 in a mass ratio of 1:1.

[0036] This embodiment also provides a preparation method for the above-mentioned antibacterial functional masterbatch, which specifically includes the following steps:

[0037] Weigh low molecular weight polylactic acid, silver ion antibacterial agent of glass carrier, nano cerium dioxide, mesoporous zirconium hydrogen phosphate, anti-thermal oxygen aging additive and zinc stearate according to the proportion, and put t...

Embodiment 3

[0039] This embodiment provides a special degradable antibacterial functional masterbatch for polylactic acid, the mass ratio of its components is as follows: 82.0kg low molecular weight polylactic acid; 13.0kg glass / zeolite carrier silver zinc ion antibacterial agent (Bactekiller BM-102SD ); 3.0kg nanometer cerium dioxide; 1.0kg mesoporous zirconium hydrogen phosphate; 0.2kg anti-thermal oxygen aging additive; 2.8kg oleic acid amide. Among them, the anti-thermal and oxidative aging additive is a compound composed of antioxidant 245 and antioxidant 626 in a mass ratio of 1:1.

[0040] This embodiment also provides a preparation method for the above-mentioned antibacterial functional masterbatch, which specifically includes the following steps:

[0041] Weigh low molecular weight polylactic acid, glass / zeolite carrier silver zinc ion antibacterial agent, nano ceria, mesoporous zirconium hydrogen phosphate, anti-thermal oxygen aging additive and oleic acid amide according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com