A kind of graphene-enhanced 20crmnti alloy steel and preparation method thereof

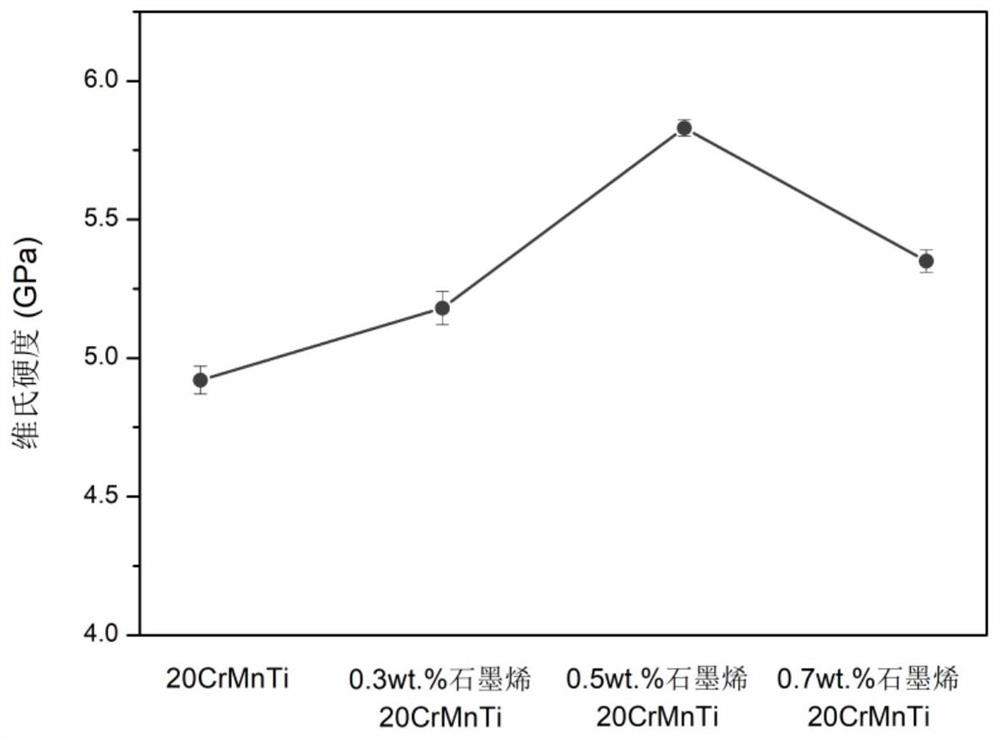

A technology of graphene and alloy steel, which is applied in the field of graphene-enhanced 20CrMnTi alloy steel and its preparation, which can solve the problems of easy agglomeration of graphene, uneven dispersion, and high cost of graphene preparation, and achieve enhanced wear resistance and excellent comprehensive performance , Improve the effect of reunion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

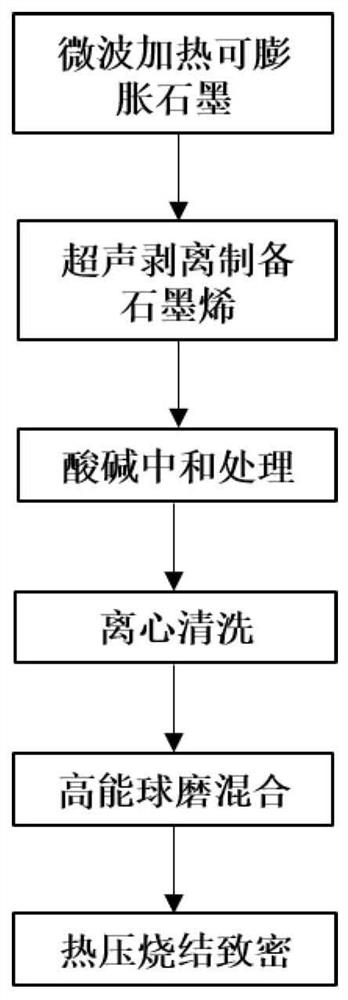

[0037] On the other hand, the present invention discloses a preparation method of graphene / 20CrMnTi alloy steel, comprising the following steps:

[0038] S1: Microwave heating of expandable graphite to obtain vermicular expanded graphite;

[0039] S2: ultrasonically exfoliating and homogenizing the expanded graphite in anhydrous ethanol, and assisting mechanical stirring during the ultrasonic exfoliation to obtain a graphene suspension;

[0040] S3: In a fume hood, the graphene suspension is subjected to acid-base neutralization treatment, the pH value is adjusted to 6-8, and centrifugal cleaning is performed for several times, and finally dried;

[0041] S4: use a planetary ball mill to perform high-energy ball milling on the dried graphene and 20CrMnTi powder in step S3 to obtain a mixed powder;

[0042] S5: Put the mixed powder obtained in step S4 into a graphite mold, place the mold in a hot-pressing furnace, perform hot-pressing sintering under an argon atmosphere, and t...

Embodiment 1

[0057] The present embodiment provides a method for preparing a graphene reinforced alloy steel, and the graphene / 20CrMnTi composite material is prepared by using the method, and the specific details are as follows:

[0058] S1: Using a household microwave oven with a power of 900W to microwave expandable graphite (80 mesh, 99.9% purity) for 30 seconds to prepare expanded graphite.

[0059] S2: Weigh 49.85 grams of 20CrMnTi metal powder and 0.15 grams of expanded graphite (the corresponding mass fraction is 0.3%). The above-mentioned expanded graphite was placed in 500 ml of anhydrous ethanol solution for ultrasonic peeling for 40 min, and mechanical stirring was assisted to form a graphene suspension.

[0060] S3: The pH value of the above-mentioned graphene suspension is 4~5, and it is subjected to acid washing and alkali washing treatment to adjust the pH. The acid washing reagent is dilute nitric acid with a concentration of 5 wt.%, and the alkali washing reagent is ammon...

Embodiment 2

[0066] The present embodiment provides a method for preparing a graphene reinforced alloy steel, and the graphene / 20CrMnTi composite material is prepared by using the method, and the specific details are as follows:

[0067] S1: Using a household microwave oven with a power of 900W to microwave expandable graphite (80 mesh, 99.9% purity) for 30 seconds to prepare expanded graphite.

[0068] S2: Weigh 49.75 g of 20CrMnTi metal powder and 0.25 g of expanded graphite (the corresponding mass fraction is 0.5%). The above-mentioned expanded graphite was placed in 500 ml of anhydrous ethanol solution for ultrasonic peeling for 40 min, and mechanical stirring was assisted to form a graphene suspension.

[0069] S3: The pH value of the above-mentioned graphene suspension is 4~5, and it is subjected to acid washing and alkali washing treatment to adjust the pH. The acid washing reagent is dilute nitric acid with a concentration of 5 wt.%, and the alkali washing reagent is ammonia water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com