Solid-liquid separator for separating livestock-poultry dung, biogas fluid and biogas dregs

A technology of solid-liquid separator and livestock and poultry manure, which is applied in the direction of presses, manufacturing tools, etc., to achieve the effects of high separation efficiency, reliable use, and low resistance to separation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

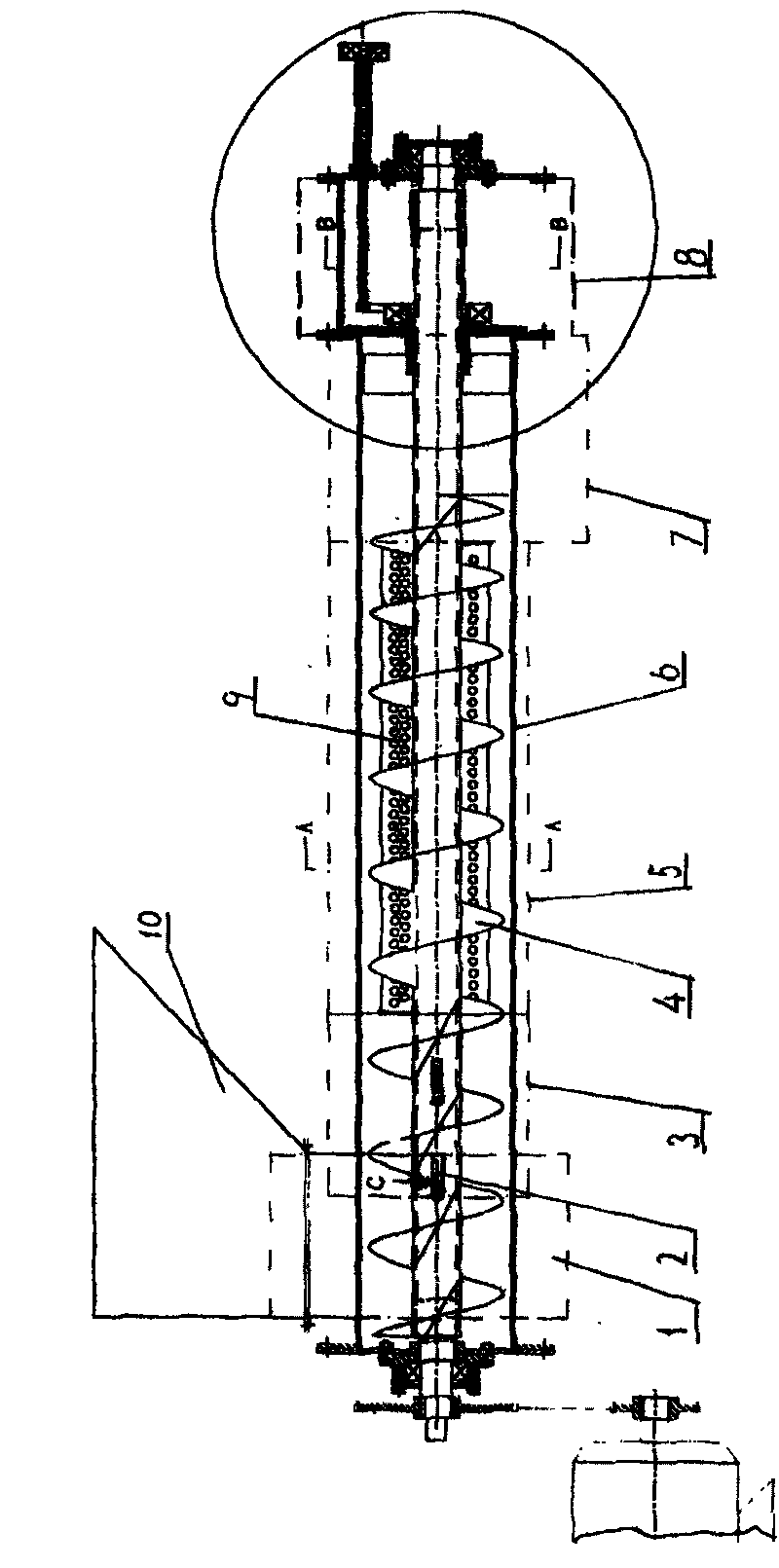

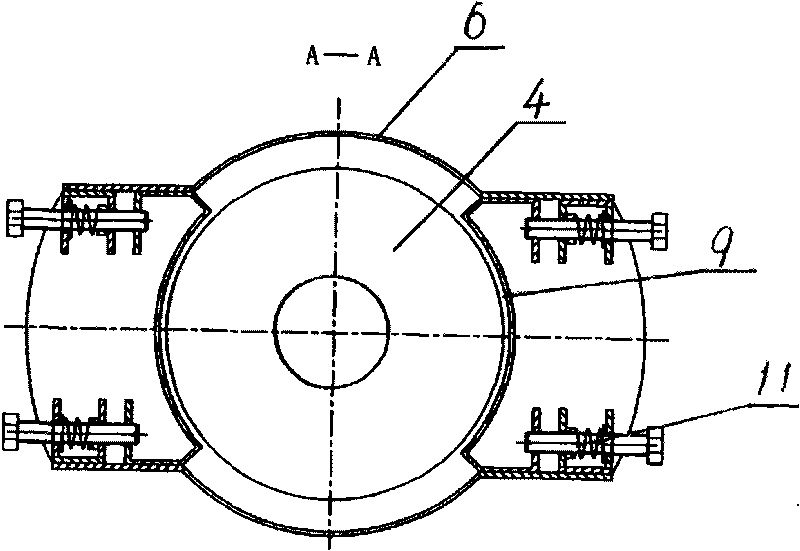

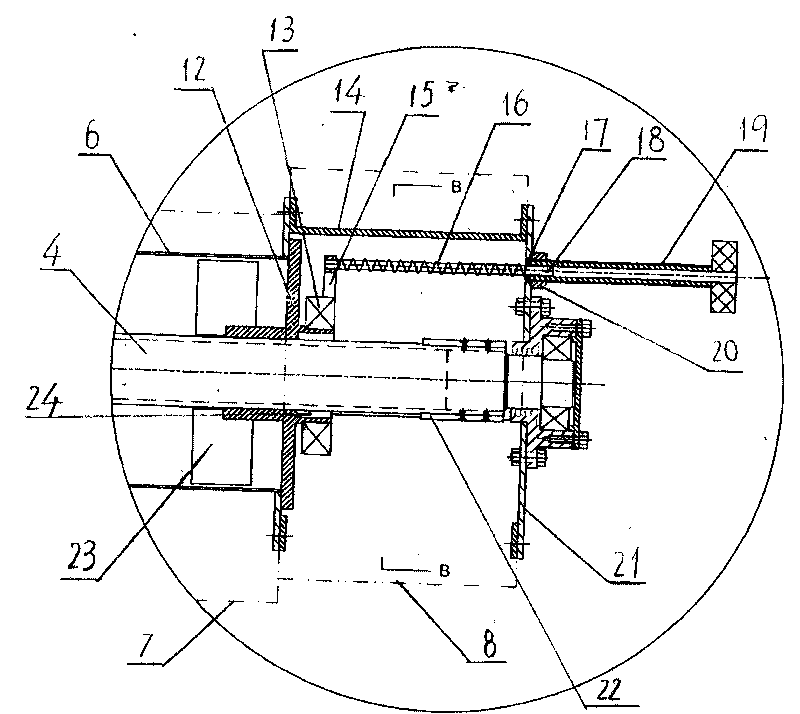

[0013] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The solid-liquid separator for livestock and poultry manure and biogas slurry and biogas slag includes a casing 6, a feed hopper 10 fitted on the front side of the casing 6, and a screw blade auger assembly 4 fitted inside the casing 6, along the The axial direction of the spiral blade auger assembly 4 is matched with the shell 6, and the feeding section 1, the stirring section 3, the separation section 5 and the solid material accumulation section 7 are arranged in sequence, and the solid material accumulation section is located on the rear end of the shell 6 7 is equipped with a solid material discharge section 8 at the rear; on the surface of the screw blade auger assembly 4 auger shaft in the stirring section 3, a stirring knife or rod 2 bent toward the direction of the separation section 5 is installed; the housing 6 is located in the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com