Three-phase separator system used in gas well liquid discharging process and using method

A three-phase separator and process technology, which is applied in earthwork drilling, wellbore/well components, valve operation/release devices, etc., can solve the problems of poor separation quality and difficult gas-liquid separation, and achieve good separation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

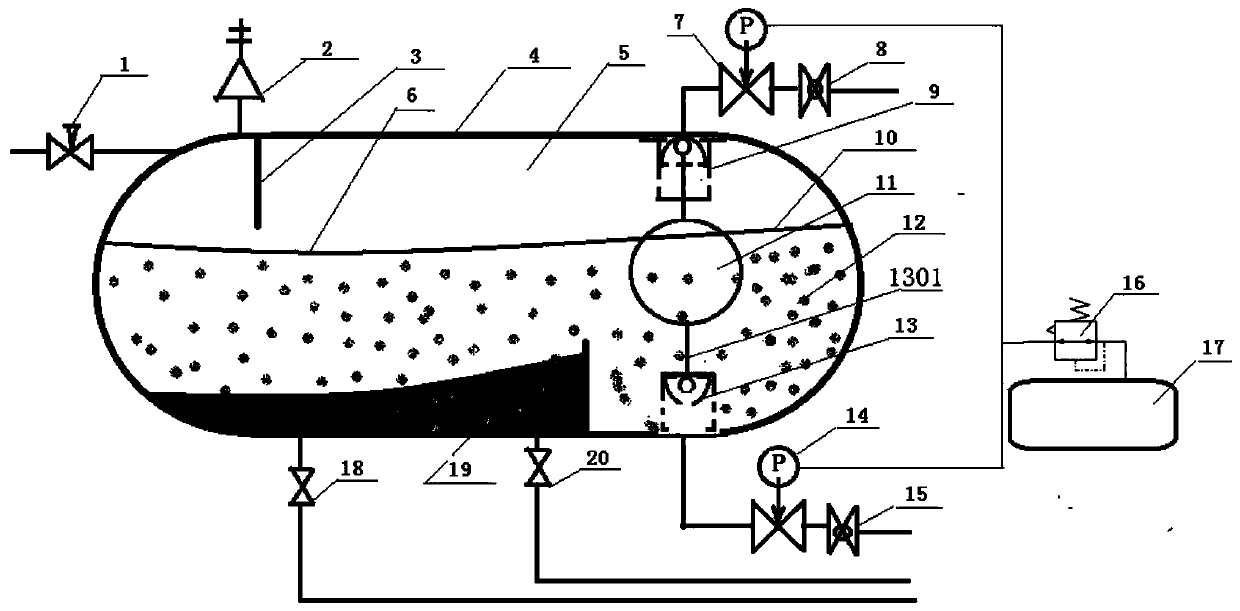

[0047] Reference figure 1 , Is a schematic structural diagram of embodiment 1 of the present invention, a three-phase separator system used in gas well drainage process, including

[0048] The three-phase separator housing 4 is provided with a separated sediment area and a separated liquid area at the bottom of the three-phase separator housing 4, and the top of the three-phase separator housing 4 is a separated gas area. A sewage outlet is provided, a liquid outlet is provided in the liquid area, and an exhaust outlet is provided in the gas area;

[0049] The gas-liquid inlet pipeline is connected to the three-phase separator housing 4, and the gas-liquid inlet pipeline is also connected with a gas-liquid inlet control valve 1;

[0050] The sewage pipe is connected with the sewage outlet of the separated sediment area in the three-phase separator shell 4;

[0051] A drain line, which is in communication with the drain port of the separated liquid zone in the three-phase separator hou...

Embodiment 2

[0057] Reference figure 1 , figure 2 with image 3 Compared with Embodiment 1, the difference of this embodiment is that the exhaust port is provided with an exhaust valve 9, the drain port is provided with a drain valve 13, and one end of the float valve 11 is connected to the exhaust valve. 9 is connected, and the other end of the float valve is connected with the drain valve 13. The two valves of the first pneumatic regulating valve 7 and the second pneumatic regulating valve 14 adopt pneumatic regulating valves of the same model, structure and working mode.

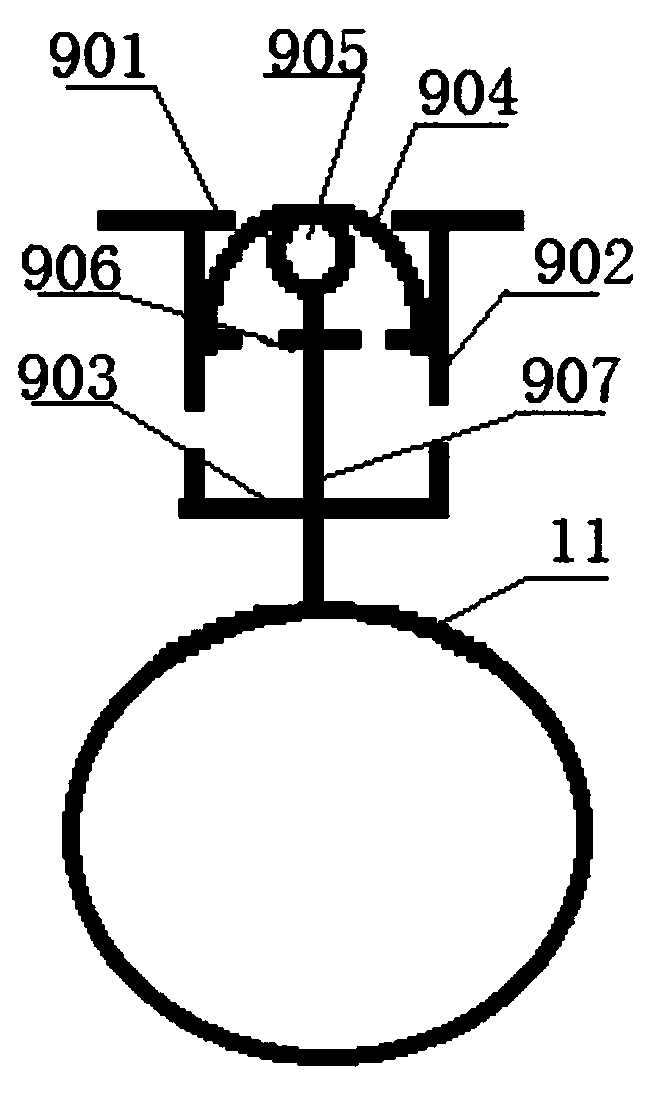

[0058] Preferably, the float valve includes a spherical float 11, an upper float connecting rod 907, a lower float connecting rod 1301, and a balance valve 905. One end of the spherical float 11 is connected to the exhaust valve 9 through the upper float connecting rod 907, and the spherical float 11 The other end is connected to the drain valve 13 through the lower float connecting rod 1301, and the ends of the upper f...

Embodiment 3

[0061] Compared with embodiment 2, the difference of this embodiment is: the exhaust valve 9 and the discharge valve 13 both include a valve seat 901, a valve housing 902, a valve displacement baffle 903, a valve head 904 and a balance Valve displacement baffle 906, valve seat 901 is connected to the inner wall of three-phase separator housing 4 around the exhaust port, one end of valve housing 902 is connected to valve seat 901, and the other end of valve housing 902 is connected to valve displacement baffle 903. The head 904 is located in the valve housing 902 and can move up and down. The valve head 904 has a semi-spherical structure. The valve head 904 of the semi-spherical structure has a hollow structure. The bottom is connected with a balance valve displacement baffle 906. The balance valve 905 floats upward. The sub-link 907 penetrates the balance valve displacement baffle 906 and is located in the valve head 904. The balance valve 905 and the connected upper float link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com