Mulberry twig bark and core separation and granulation combined machine

A combined machine and granulation technology, used in solid separation, classification, chemical instruments and methods, etc., can solve the problems of difficult separation of skin and mulberry branch debris, excessive mulberry branch fragmentation, and large fiber damage, and achieve large particle materials. The effect of less, less fiber damage and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

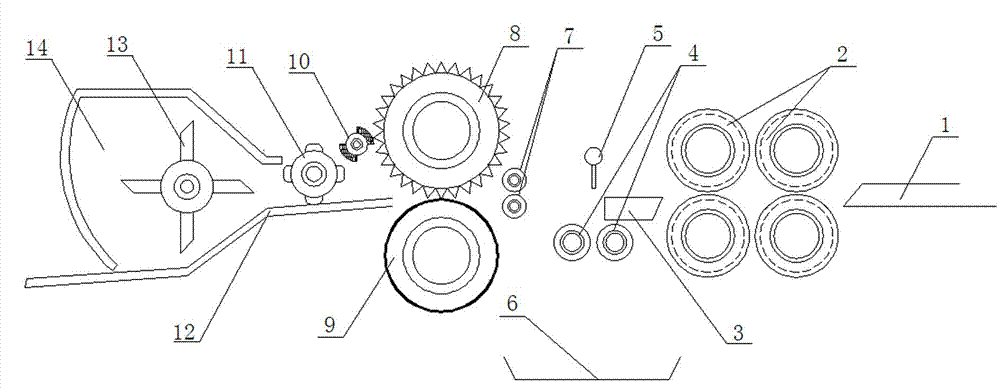

[0017] Feed several mulberry strips side by side to the feeding trough 1 with the big end in front, and enter the peeling device 2 under the action of the peeling roller. Peeling device 2 is made up of two groups of spiral rollers. Each set of upper and lower rollers is provided with left-handed and right-handed screw teeth on the outer surface of the rollers, and the two sets of spiral rollers are equipped with pressure-adjustable elastic springs. Feeding the mulberry branches, under the moderate pressure of the spiral roller and the reverse twisting force and tearing of the left and right-handed tooth bodies, the mulberry bark will be cracked and peeled off from the branches, and the branches will not be caused by excessive force. The stems are excessively broken, making it difficult to separate the bark from the stems. The mulberry branches after the preliminary separation of the bark and the bark move forward under the action of the rollers and enter the return chute 3, a...

Embodiment 2

[0019] In order to give full play to the technical advantages of the present invention, on the basis of Example 1, this embodiment further optimized the structural parameters of the skin-core separation device in the mulberry branch skin-core separation and granulation combined machine through multiple tests. Design, including the pitch, helix angle, normal spacing of the first and second sets of rollers, etc. of the surface threads of the spiral rollers in the peeling device 2

[0020] In order to obtain the pitch parameters of the optimal spiral roller thread, the present invention trial-produces a spiral roller with a helix angle of 20° and a pitch of 5mm, 8mm, 10mm, and 12mm, and carries out the spiral roller pitch on the mulberry bark core separation and granulation combined machine Effect experiment on the separation effect of mulberry bark and core. The normal spacing of the first and second sets of spiral rollers are respectively 5mm and 4mm. During the experiment, th...

Embodiment 3

[0037] On the basis of Example 1, this embodiment further optimizes the design of the structural parameters of the granulation device of the mulberry bark core separation and granulation combined machine through a number of specific tests, including the axial tooth height on the surface of the truncating roller 8 , tooth pitch, lateral displacement distance of smooth roller 9, and normal distance between cut-off roller 8 and smooth roller 9, etc.

[0038] In order to obtain the optimal tooth height parameters of the axial triangular spur teeth on the surface of the cut-off roller 8, cut-off rollers with a tooth pitch of 8mm and a tooth height of 2mm, 4mm, 6mm, and 8mm were trial-produced in this embodiment, and the axial tooth height was adjusted. Influence experiment of granulation effect. The lateral displacement distance of the smooth roller 9 is designed to be 3 mm, and the normal distance between the cut-off roller 8 and the smooth roller 9 is 1 mm. During the experiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com