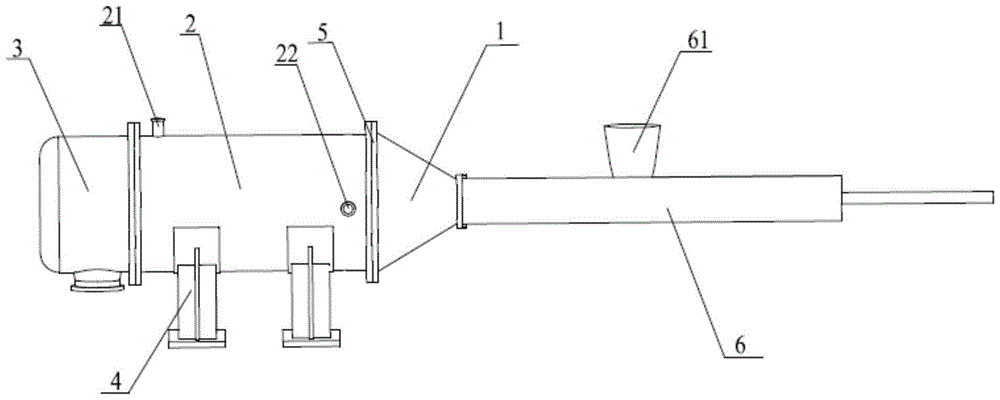

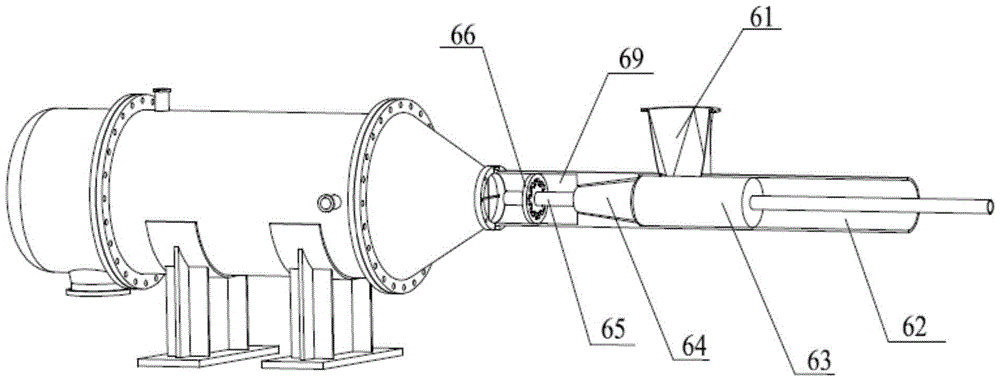

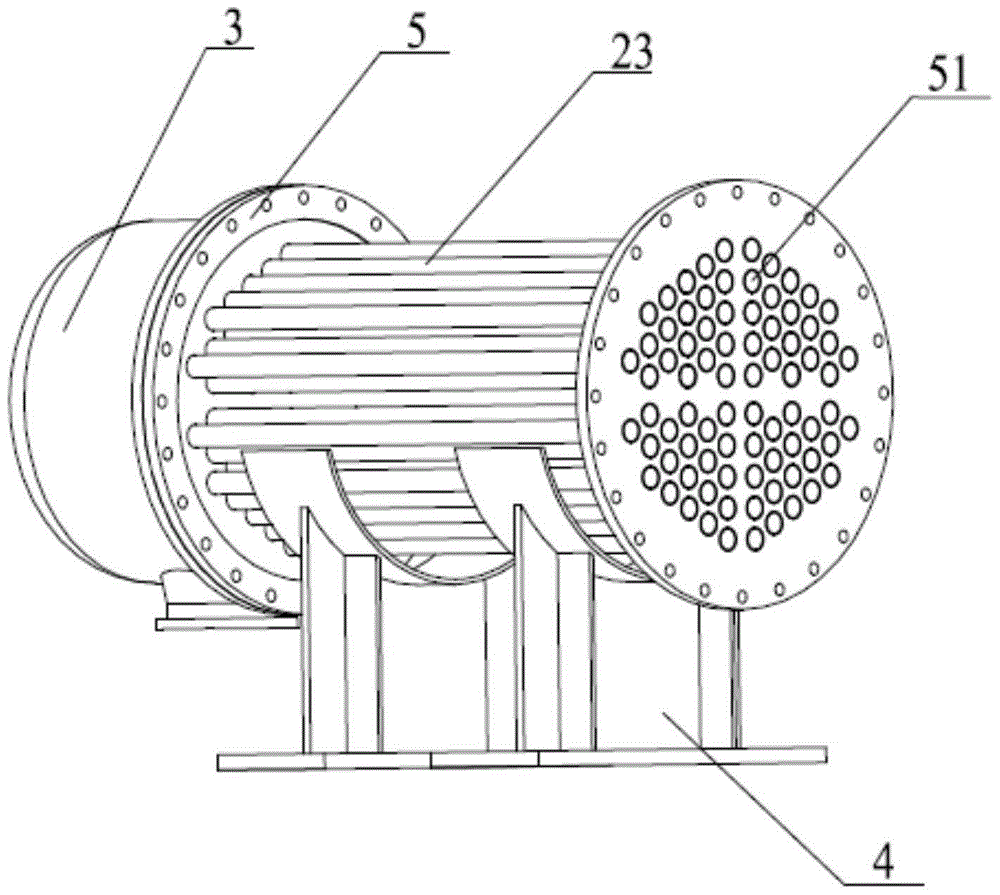

Sewage heat pretreatment wall breaking device and sewage treatment method

A technology for sludge treatment and sludge, which is applied in the field of sludge thermal pretreatment wall-breaking device, which can solve the problem of increasing the amount of water and bound water inside the sludge floc particles, increasing the energy cost of sludge drying and dehydration, and high resistance to filtration and dehydration and other problems, to achieve the effect of stable work, strong practicability, and good flocculation and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] A method for sludge treatment using a wall-breaking device as described, comprising the steps of:

[0064] Step 1: Filter the sludge that has been flocculated and concentrated by polyacrylamide using a filter screen with a pore size of 10mm, wherein the water content of the concentrated sludge is 80wt%, and the amount of polyacrylamide added is 0.2wt %, the polyacrylamide is a cationic polyacrylamide, the cationic degree of the cationic polyacrylamide is 45%, and the number average molecular weight of the polyacrylamide is 5.5 million;

[0065] Step 2: The sludge obtained in Step 1 is thermally pretreated at 80° C. for 40 minutes using the wall-breaking device, wherein the energy for the heat treatment comes from the steam generating device;

[0066] Step 3: Mechanically dewatering the sludge obtained in Step 2 until the water content reaches 45 wt%;

[0067] Step 4: Dry the sludge obtained in Step 3 to a water content of 10wt% through a sludge dryer.

example 2

[0069] A method for sludge treatment using a wall-breaking device as described, comprising the steps of:

[0070] Step 1: Filter the sludge flocculated and concentrated by polyacrylamide using a filter screen with a pore size of 18mm, wherein the water content of the concentrated sludge is 90wt%, and the amount of polyacrylamide added is 0.35wt %, the polyacrylamide is a cationic polyacrylamide, the cationic degree of the cationic polyacrylamide is 50%, and the number average molecular weight of the polyacrylamide is 8 million;

[0071] Step 2: The sludge obtained in Step 1 is thermally pretreated at 100° C. for 60 minutes using the wall-breaking device, wherein the energy for heat treatment comes from waste heat of exhaust gas;

[0072] Step 3: mechanically dehydrating the sludge obtained in Step 2 until the water content reaches 42wt%;

[0073] Step 4: Dry the sludge obtained in Step 3 to a water content of 8 wt% through a sludge dryer.

example 3

[0075] A method for sludge treatment using a wall-breaking device as described, comprising the steps of:

[0076] Step 1: Filter the sludge flocculated and concentrated by polyacrylamide using a filter screen with a pore size of 15mm, wherein the water content of the concentrated sludge is 85wt%, and the amount of polyacrylamide added is 0.28wt %, the polyacrylamide is a cationic polyacrylamide, the cationic degree of the cationic polyacrylamide is 47%, and the number average molecular weight of the polyacrylamide is 7 million;

[0077] Step 2: The sludge obtained in Step 1 is thermally pretreated at 90° C. for 50 minutes using the wall-breaking device, wherein the energy for the thermal treatment comes from oilfield associated gas;

[0078] Step 3: Mechanically dewatering the sludge obtained in Step 2 until the water content reaches 40wt%;

[0079] Step 4: Dry the sludge obtained in Step 3 to a water content of 15 wt% through a sludge dryer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com