Multi-shaft crushing dryer of rotary drum

A technology of dryers and drums, applied in dryers, drying, non-progressive dryers, etc., can solve problems such as difficult installation and maintenance, long shaft length, easy deformation, etc., to prolong service life and reduce maintenance The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

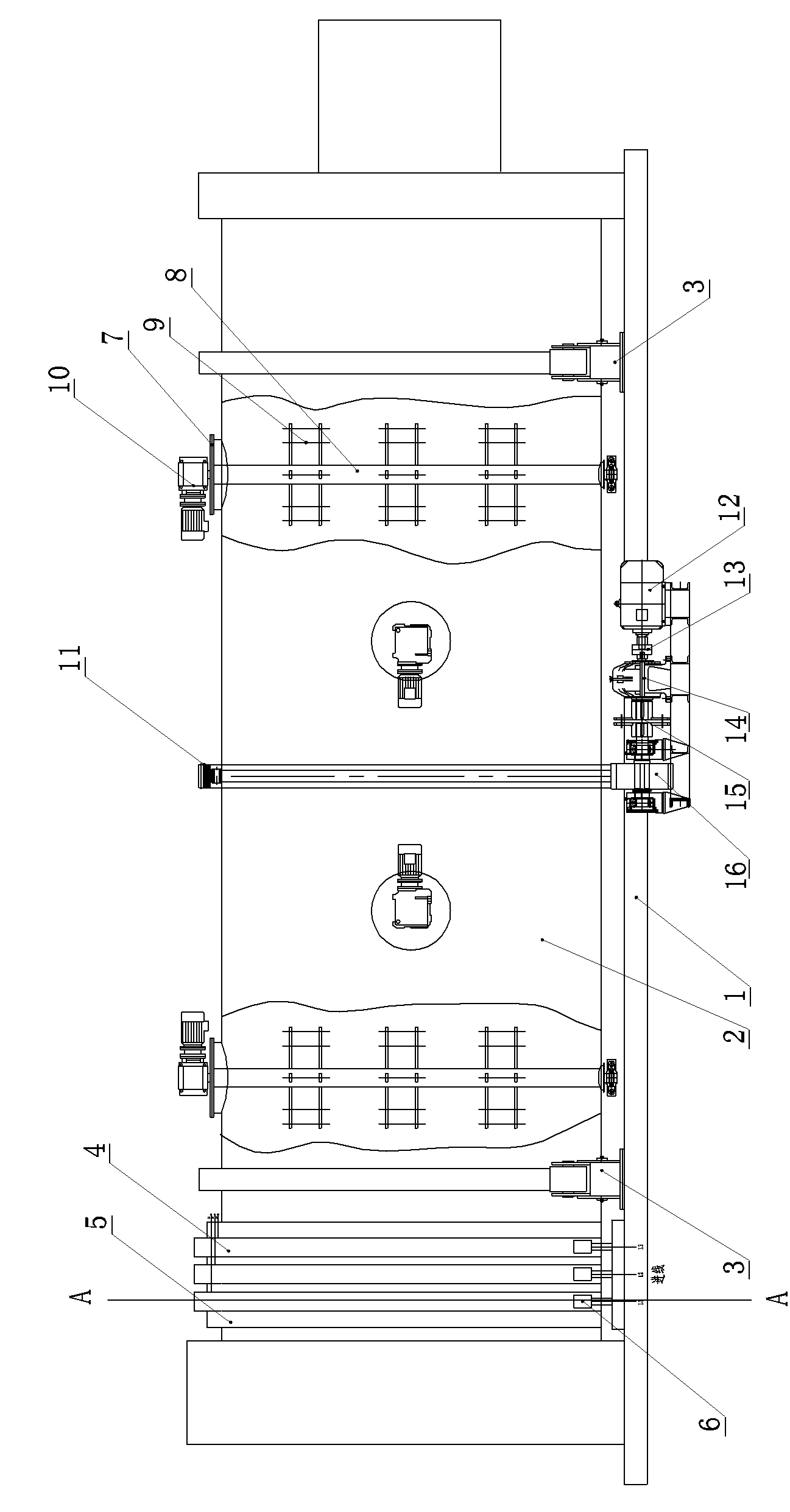

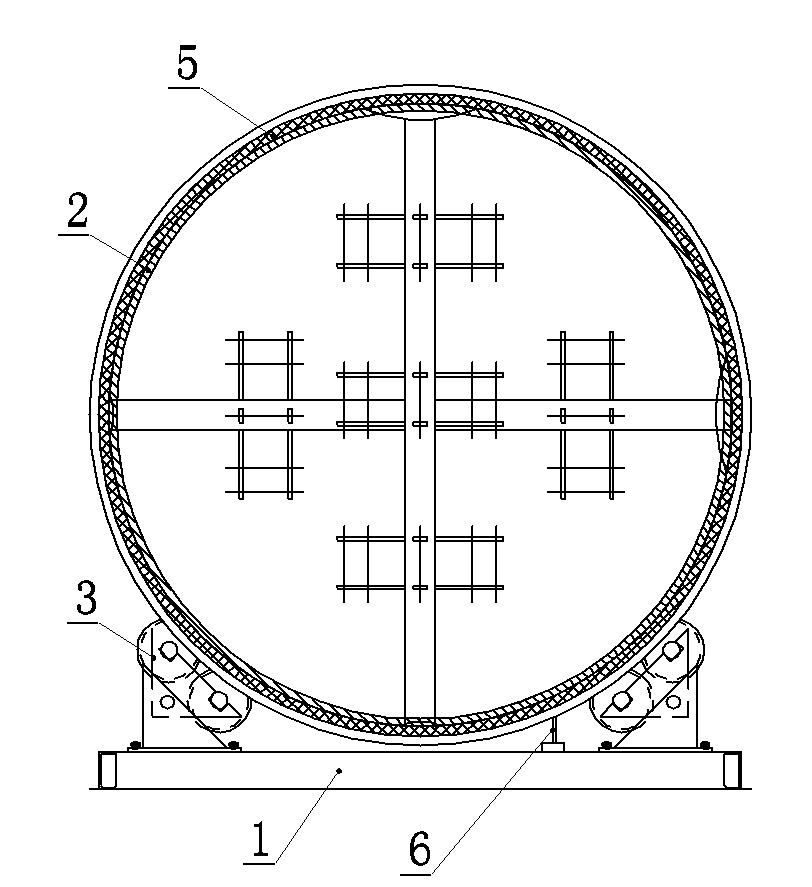

[0023] Embodiment one: see Figure 1-Figure 2 , a drum multi-shaft crushing dryer in the figure, including a dryer frame, a drum, a driving device, and a set of idlers. The set of idlers is installed on the frame of the dryer, and the drum is supported on On the roller set, the driving device drives the drum to rotate. The drum is equipped with several vertical crushing shafts crossing the wall of the drum, and the two ends of the vertical crushing shaft are installed on the wall of the drum through flanges. A number of vertical shafts are arranged in a cross; one end of each vertical shaft is connected with a crushing motor; the end of the drum is provided with at least two rotating rings, and the rotating rings are connected to the outer wall of the drum. Insulation between them, the transfer ring is connected to the crushing motor through wires, and a brush that matches and contacts the transfer ring is provided on the dryer frame at the lower part of the transfer ring, and...

Embodiment 2

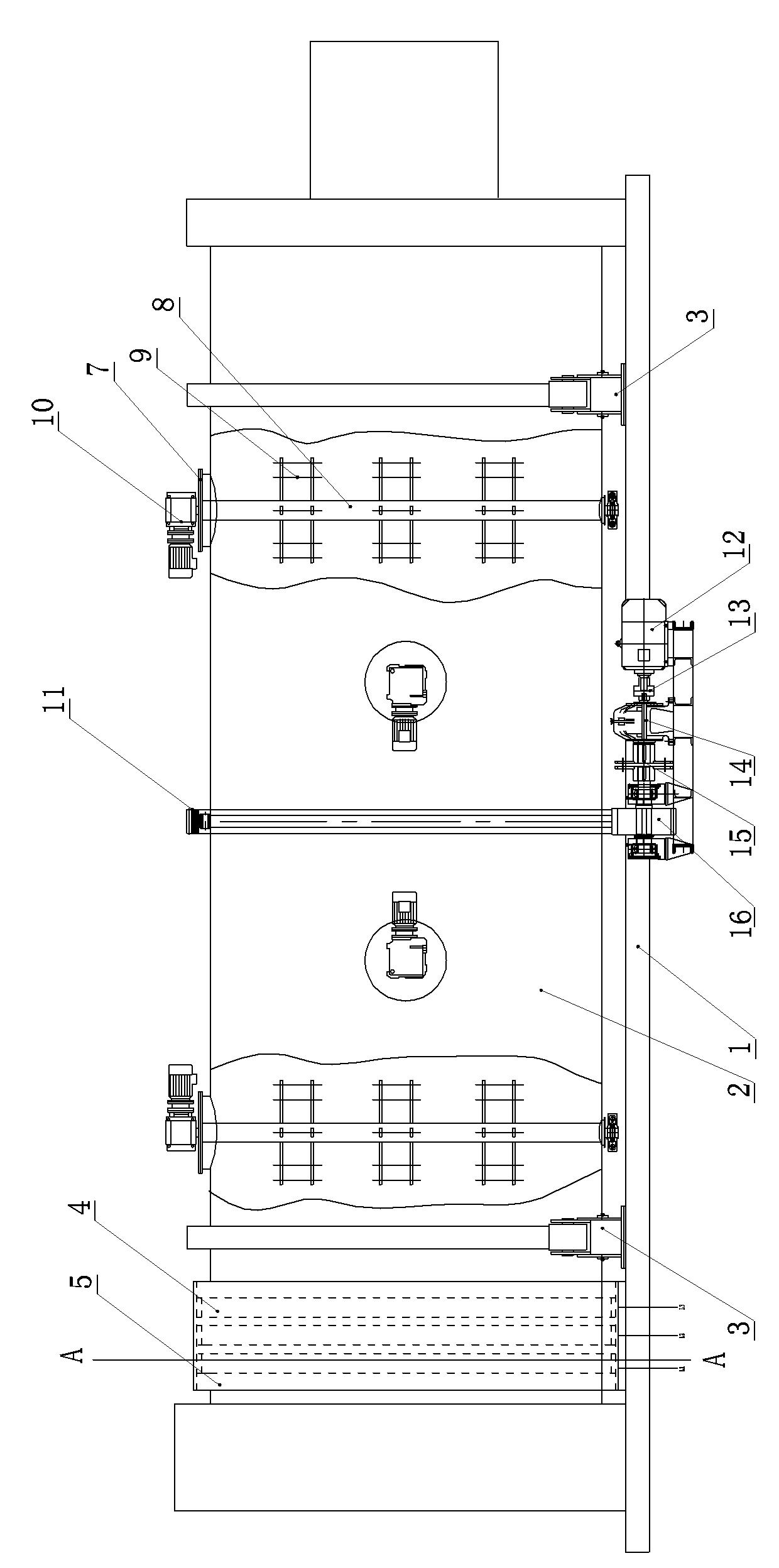

[0028] Embodiment two: see Figure 3-Figure 4 , a drum multi-shaft crushing dryer in the figure, including a dryer frame, a drum, a driving device, and a set of idlers. The set of idlers is installed on the frame of the dryer, and the drum is supported on On the roller set, the driving device drives the drum to rotate. The drum is equipped with several vertical crushing shafts crossing the wall of the drum, and the two ends of the vertical crushing shaft are installed on the wall of the drum through flanges. Several vertical shafts are intersected; one end of each vertical shaft is connected to a crushing motor; the end of the dryer rack is provided with at least two wire transfer rings, and the wire transfer rings are connected to the The large frames of the dryer are insulated, the wire transfer ring is connected to the power supply through wires, and the outer wall of the drum is provided with a brush that matches and contacts the wire transfer ring, and the brush is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com