Vibrating dust-collection type scattering machine

A technology of dispersing machine and vibrating screen, applied in the field of machinery, can solve the problems of material agglomeration due to moisture, unable to work, energy consumption, etc., and achieve the effect of avoiding air pollution, good dispersing effect, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

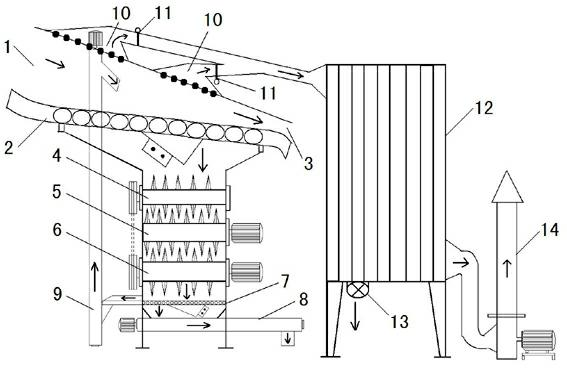

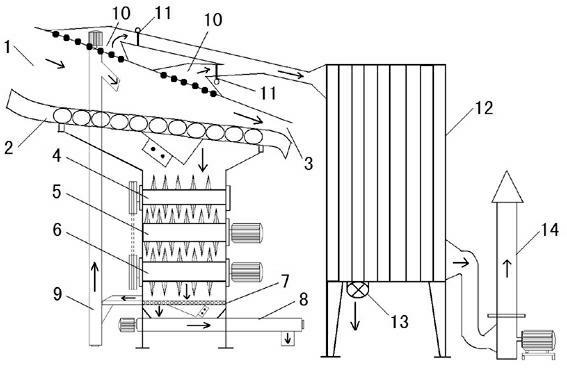

[0016] like figure 1 As shown, the vibrating dust collection type dispersing machine is mainly suitable for various powder materials or granular materials that are agglomerated due to moisture, and need to be broken up and loosened to remove large debris.

[0017] There is a feeding port 1 on the upper part of the frame, which is used to use some kind of feeding equipment to feed the machine; the lower part of the feeding port 1 is a vibrating screen A2, and the vibrating screen A2 is composed of a spring or rubber spring and a machine. The sieve removes large debris from the incoming material and also has the effect of vibrating and dispersing the material. The sieve hole of the vibrating machine can be determined according to the different materials; the vibrating screen A2 is placed obliquely, and The contact part of port 1 is relatively high, and the other side corresponding to feed port 1 is relatively low, forming a miscellaneous discharge port 3, which is used to discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com