Nickel-slag porous microcrystalline material and preparation method thereof

A technology of microcrystalline material and nickel slag, which is applied in the field of nickel slag porous microcrystalline material and its preparation, can solve problems such as low mechanical strength, and achieve the effects of reducing production cost and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

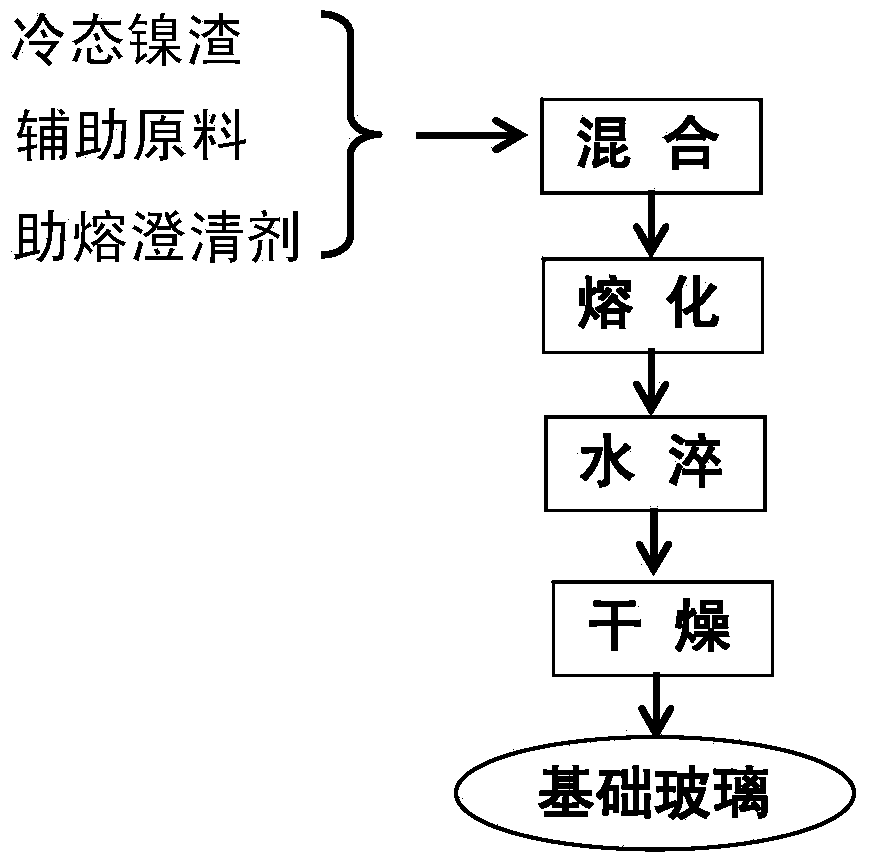

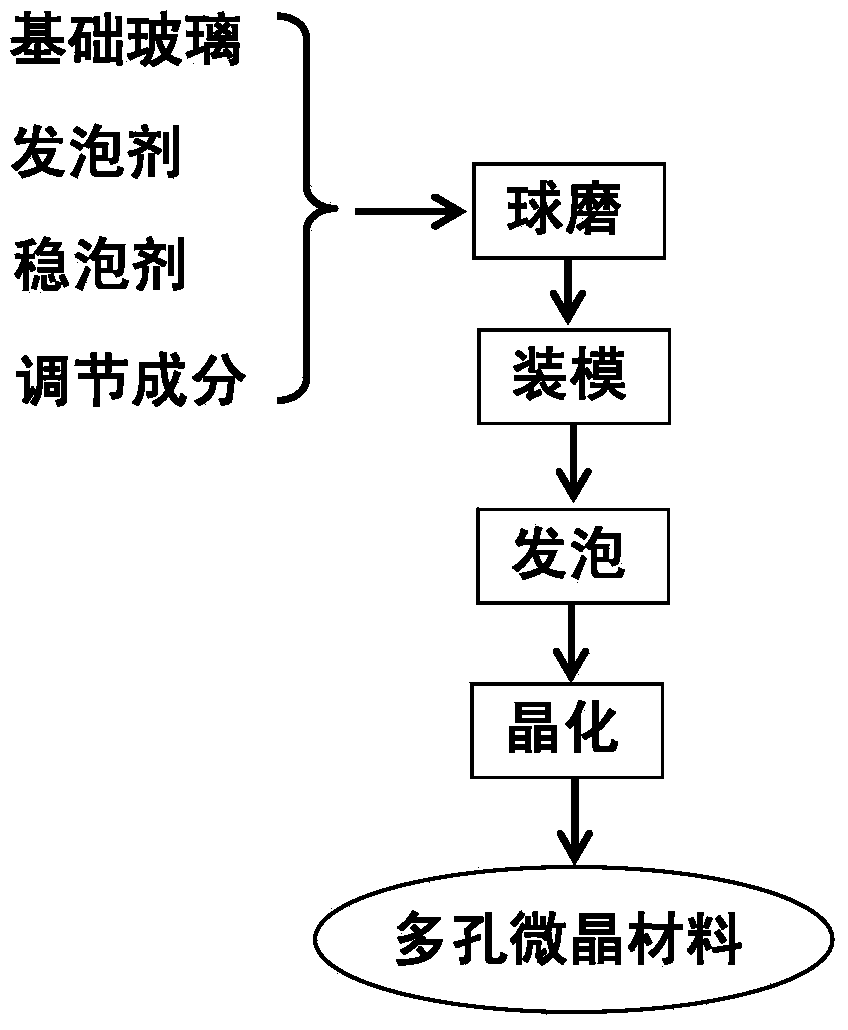

[0060] (1) Preparation of basic glass

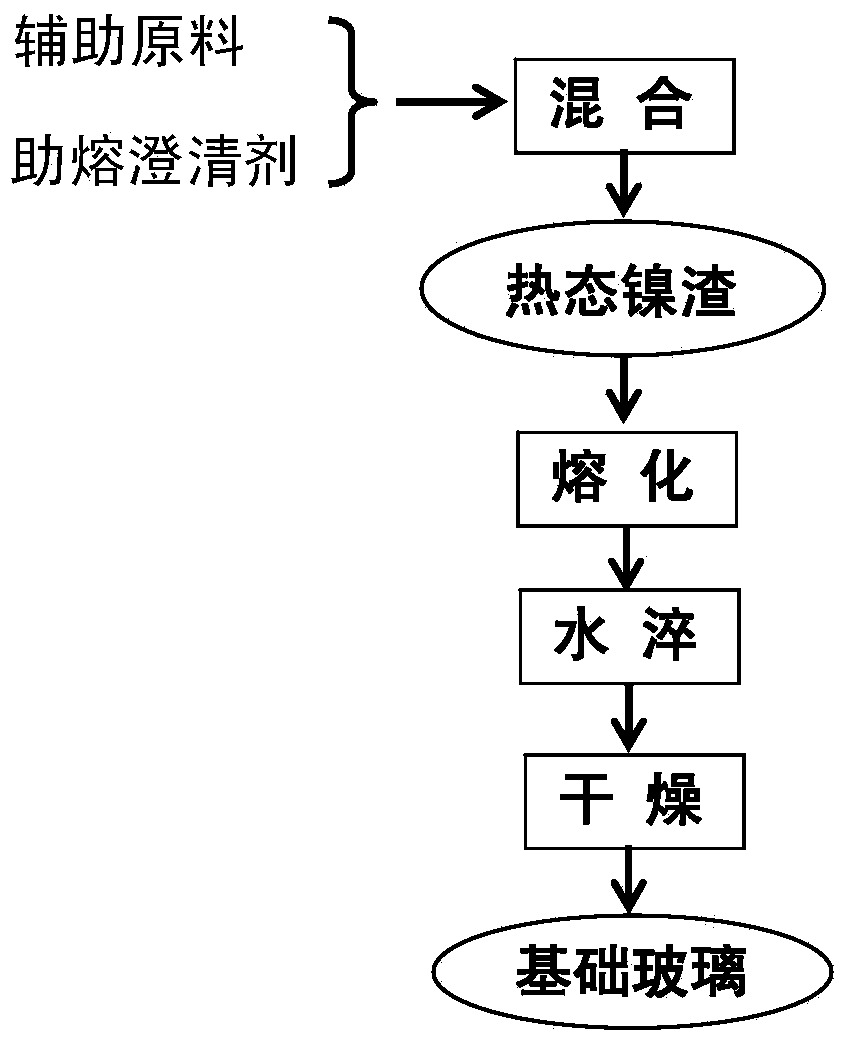

[0061] Crush the cold nickel slag and various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 60.0 kg of cold nickel slag, 8.0 kg of calcium carbonate, 9.0 kg of aluminum oxide, 18.0 kg of silicon dioxide, and 9.0 kg of Kilograms of sodium carbonate, 3.0 kilograms of potassium carbonate. Put various raw materials into a mixer or agitator, add 5.0% water of the total weight of the raw materials, and stir evenly to make a basic glass batch. Melt the basic glass batch material in the range of 1485-1520°C for 2.0-4.0h to make a glass melt, and then keep it in the range of 1350-1370°C for 1.0-3.0h to homogenize and clarify the glass liquid to obtain a high temperature molten state glass melt (such as figure 1 shown).

[0062] Or crush various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 8.0 kg of calcium carbonate, 9.0 kg of aluminum oxide, 18.0 kg of silicon dioxide, 9.0 kg of s...

Embodiment 2

[0073] (1) Preparation of basic glass

[0074] Crush the cold nickel slag and various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 55.0 kg of cold nickel slag, 8.0 kg of calcium carbonate, 2.0 kg of calcium fluoride, 9.0 kg of aluminum oxide, and 2.0 kg of Kg sodium nitrate, 1.0 kg barium carbonate, 18.0 kg silicon dioxide, 9.0 kg sodium carbonate, 3.0 kg potassium carbonate. . Put various raw materials into a mixer or agitator, add 5.0% water of the total weight of the raw materials, and stir evenly to make a basic glass batch. Melt the basic glass batch material in the range of 1470-1500°C for 2.0-4.0h to make a glass melt, and then keep it in the range of 1300-1350°C for 1.0-3.0h to homogenize and clarify the glass liquid to obtain a high temperature molten state glass melt (such as figure 1 shown).

[0075] Or crush various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 8.0 kg of calcium carbonate, 2.0 kg of...

Embodiment 3

[0086] (1) Preparation of basic glass

[0087] Crush the cold nickel slag and various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 65.0 kg of cold nickel slag, 7.0 kg of calcium carbonate, 8.5 kg of aluminum oxide, 15.5 kg of silicon dioxide, and 9.0 kg of Kg of sodium carbonate, 3.5 kg of potassium carbonate, 2.0 kg of sodium nitrate, 0.5 kg of zinc oxide. Put various raw materials into a mixer or agitator, add 5.0% water of the total weight of the raw materials, and stir evenly to make a basic glass batch. Melt the basic glass batch material in the range of 1485-1520°C for 2.0-4.0h to make a glass melt, and then keep it in the range of 1350-1370°C for 1.0-3.0h to homogenize and clarify the glass liquid to obtain a high temperature molten state glass melt (such as figure 1 shown).

[0088] Or crush various auxiliary materials, then pass through a 40-mesh sieve, and accurately weigh 7.0 kg of calcium carbonate, 8.5 kg of aluminum oxide, 15.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com