Artificial wetland system taking oyster shell-waste brick-zeolite as composite filler

A technology of constructed wetland system and composite filler, which is applied in the field of water pollution control, can solve the problems of inhibiting the growth of plants and microorganisms, and increasing the pH value of the effluent of the system, and achieves the effects of being conducive to degradation, enhancing processing capacity and optimizing operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

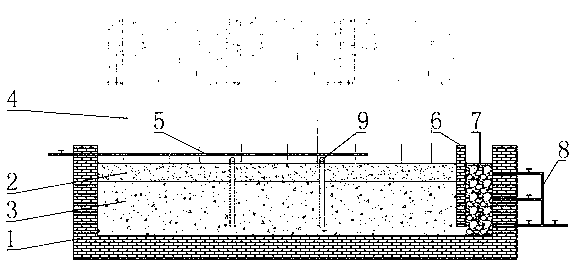

[0031] Embodiment 1: The sewage is pumped into the constructed wetland pool body 1 by the water inlet pump, and the water is uniformly distributed on the surface of the soil layer 2 through the branch-shaped perforated water distribution pipe 5, and then the sewage flows through the sea oyster shell-waste brick-zeolite composite filler layer 3 It is collected into the water collection area 7 through the deflector 6, and finally the outlet water is discharged through the outlet pipe 8, and the outlet water level in the constructed wetland system can be adjusted through the outlet pipe 8.

specific Embodiment approach 2

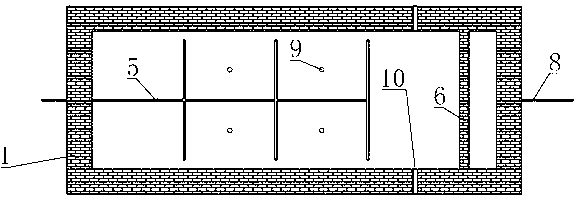

[0032] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the patent of the present invention includes a vertical subsurface flow constructed wetland model. The system packing layer includes an upper layer and a lower layer (namely, the soil layer 2 and the sea oyster shell-waste brick-zeolite composite packing layer 3), and the upper layer is 10-20 cm Thick soil layer 2 (local red soil in Fujian, mixed with river sand and humus), sieved; the lower layer is 50-100 cm thick oyster shell-waste brick-zeolite composite filler layer 3, particle size range: 5- 30 mm. The filler filling method is "mixed positive and negative particle sizes" with large particle size distribution difference. The particle size of the upper filler is the smallest.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 and figure 2 This embodiment is described. In this embodiment, an outlet pipe 8 is provided in the constructed wetland system. The outlet pipe 8 can create an unsaturated layer and a saturated layer in the sea oyster shell-waste brick-zeolite composite filler layer 3 in the system by adjusting the water level. Layer, so as to realize the effective synergy of aerobic ammonium oxidizing bacteria, nitrite oxidizing bacteria, anammox oxidizing bacteria and denitrifying bacteria, enrich the way of nitrogen removal in the system, and greatly improve the ammonia nitrogen removal efficiency of the patent of the present invention.

[0034] Specific implementation mode four: combination figure 1 and figure 2 Describe this embodiment. In this embodiment, a branch-shaped perforated water distribution pipe 5 is arranged on the surface of the soil layer 2 of the constructed wetland. The setting of the branch-shaped perforat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com