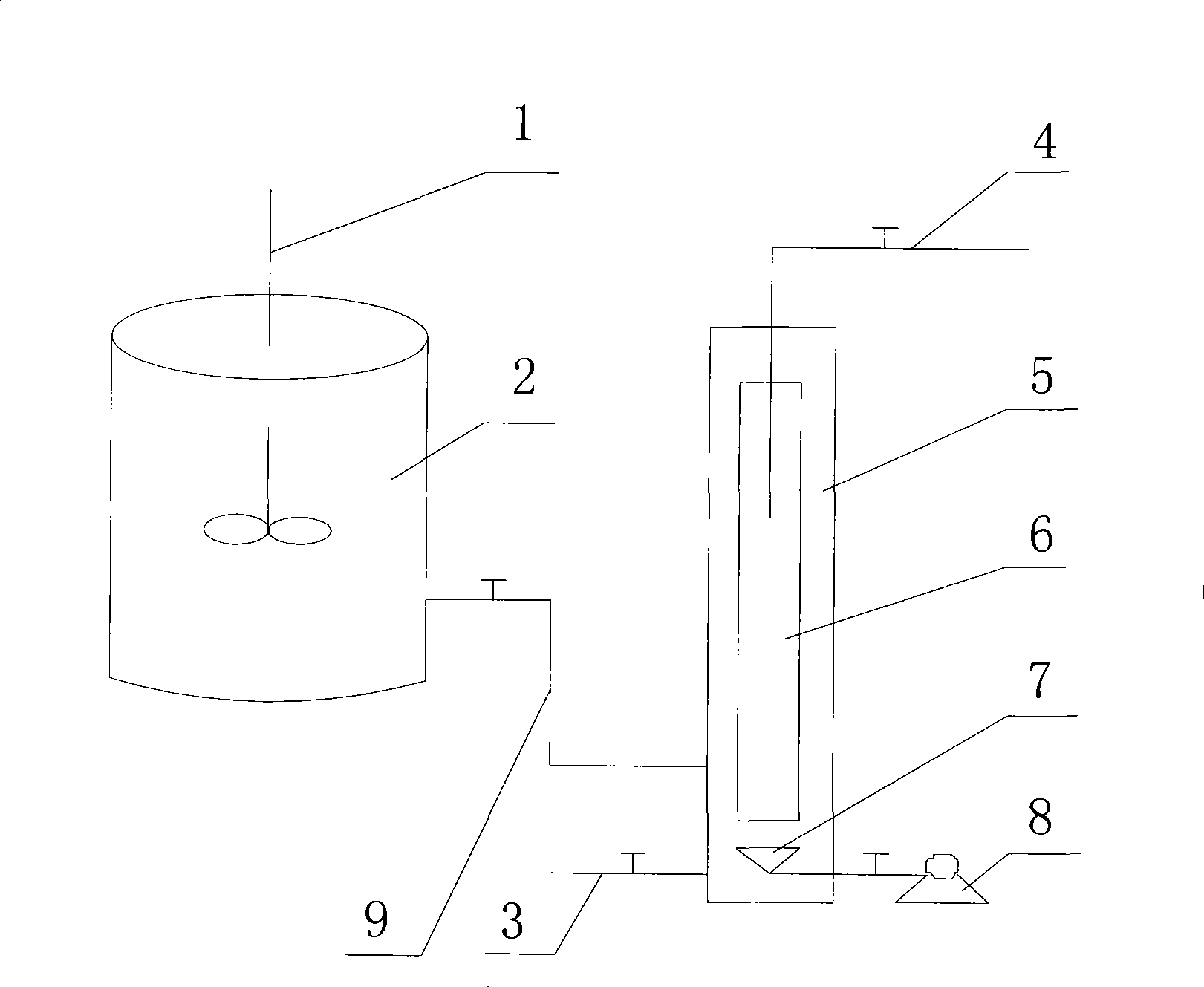

Treatment method and equipment for high phosphorus haematite mineral processing acid wastewater

A technology for acid wastewater and treatment equipment, which is applied in the directions of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Short running cycle of the agent and other problems, to achieve the effect of online circulation and efficient utilization of resources, good phosphorus removal effect, and good solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of treatment method of high phosphorus hematite beneficiation acidic waste water, it comprises the steps:

[0031] 1) Preparation of modified red mud:

[0032] (1) Dry the red mud in a drying oven at 90°C for 2 hours, then crush it (crushed with a mortar) and pass it through a 20-mesh sieve, and take the under-sieved material (as the object of modification) to obtain red mud powder for later use;

[0033] (2) According to red mud powder: hydrochloric acid = 40g: 1L, select red mud powder and hydrochloric acid, wherein the mass concentration of hydrochloric acid is 5%; put red mud powder in hydrochloric acid, fully stir in a water bath at 60°C for 1 hour, After cooling, the mixture is obtained;

[0034] (3) Add ammonia water to the mixed solution and stir, adjust the pH to 7.5, and let stand (so that the suspended matter in the mixed solution is fully precipitated); pour out the supernatant, and wash the precipitated substance with distilled water 5 times (to rem...

Embodiment 2

[0041] A kind of treatment method of high phosphorus hematite beneficiation acidic waste water, it comprises the steps:

[0042] 1) Preparation of modified red mud:

[0043] (1) Dry the red mud in a drying oven at 100°C for 2.5 hours, then crush it (crushed with a mortar) and pass it through a 20-mesh sieve, and take the material under the sieve (as the object of modification) to obtain red mud powder for later use;

[0044] (2) According to red mud powder: hydrochloric acid = 50g: 1L, select red mud powder and hydrochloric acid, wherein the mass concentration of hydrochloric acid is 7%; put red mud powder in hydrochloric acid, fully stir in a water bath at 80°C for 1.5h , to obtain a mixed solution after cooling;

[0045] (3) Add ammonia water to the mixed solution and stir, adjust the pH to 8.0, and let it stand (so that the suspended matter in the mixed solution is fully precipitated); pour out the supernatant, and wash the precipitated substance with distilled water 7 tim...

Embodiment 3

[0051] A kind of treatment method of high phosphorus hematite beneficiation acidic waste water, it comprises the steps:

[0052] 1) Preparation of modified red mud:

[0053] (1) Dry the red mud in a drying oven at 90-105°C for 2-3 hours, then crush it (crushed with a mortar) and pass through a 20-mesh sieve, and take the under-sieved material (as the object of modification) to obtain red mud powder, spare;

[0054] (2) According to red mud powder: hydrochloric acid = 40g ~ 60g: 1L, select red mud powder and hydrochloric acid, wherein the mass concentration of hydrochloric acid is 5 ~ 10%; put red mud powder in hydrochloric acid, in 60 ~ 100 ℃ water bath Fully stir in the pot for 1-2 hours, and get the mixed solution after cooling;

[0055] (3) Add ammonia water to the mixed solution and stir, adjust the pH to 7.5-8.5, and let it stand (so that the suspended matter in the mixed solution is fully precipitated); pour out the supernatant, and wash the precipitated substance with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com