Steel slag property optimized handling method

A treatment method and steel slag technology, which is applied in the field of steel slag performance optimization, can solve the problems of low effective active component content, large fluctuation of steel slag composition, and restricted application, so as to reduce the cost, improve the volume stability and hydraulic activity, The effect of reducing costs and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Based on the original steel slag, add components to the original steel slag to adjust the raw materials limestone (4.47% as CaO), clay (4.47% as SiO 2 Calculated as 2.19%) and bauxite (as Al 2 o 3 Calculated as 1.86%), mixed and ground together to a specific surface area of 325m 2 / Kg. The steel slag added with component adjustment raw materials was calcined in a silicon-molybdenum rod furnace at 1600°C, and the firing temperature was 1300°C. After the calcination is completed, the optimized steel slag is obtained through air cooling at the slag outlet, rapid cooling, granulation, and grinding.

[0022] After the above optimized treatment, the f-CaO content of the steel slag is about 1.2%, the pressure steaming stability is qualified, and the 28-day activity index is about 89.6%.

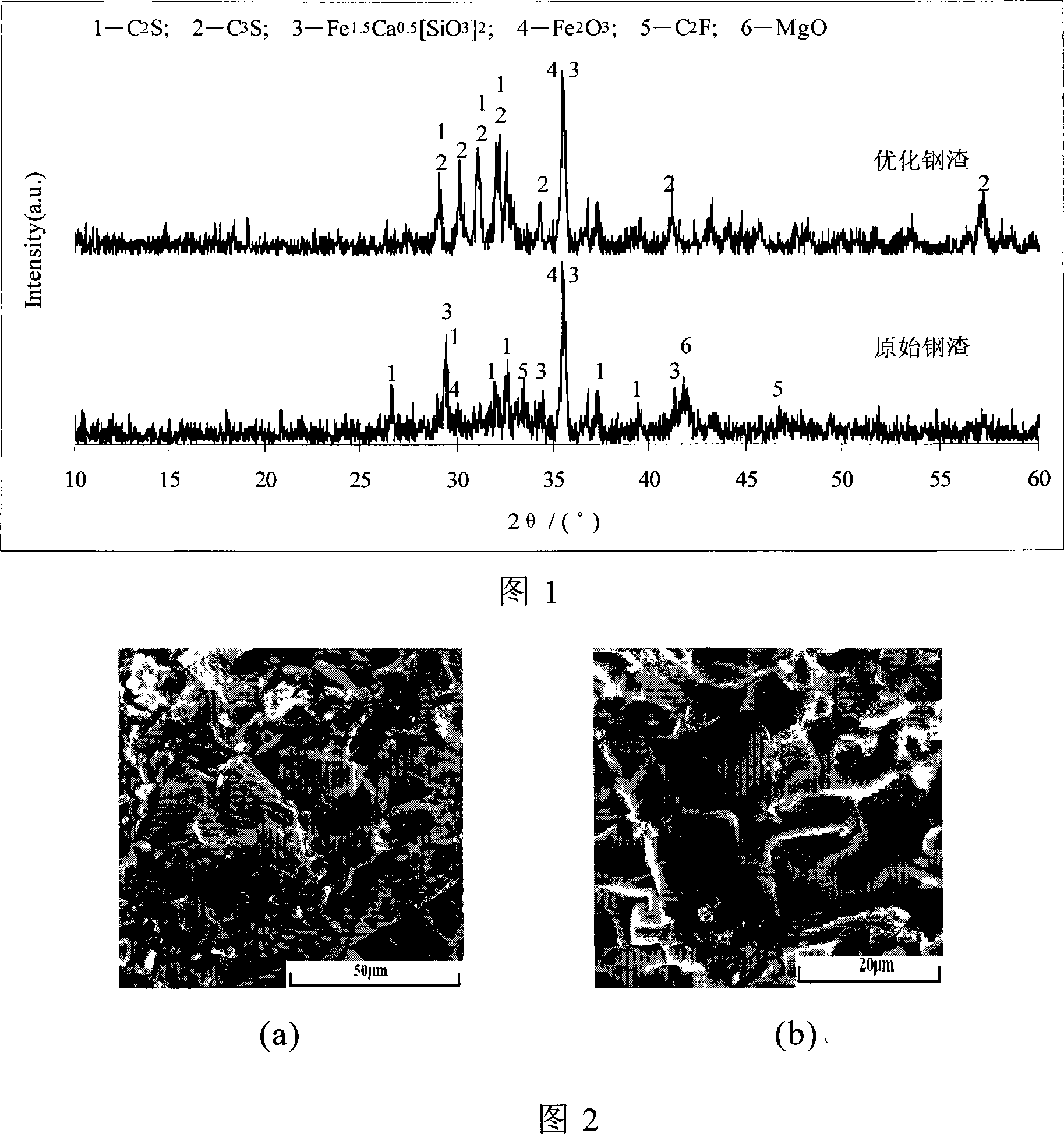

[0023] The XRD analysis diagrams of the steel slag before and after optimization are shown in Figure 1. The upper figure is the optimized XRD analysis chart, and the lower figure is the...

Embodiment 2

[0028] Add components to the original steel slag to adjust the raw materials limestone (6.82% as CaO), clay (6.82% as SiO 2 Calculated as 1.52%) and bauxite (as Al 2 o 3 Calculated as 2.11%), mixed and ground together to a specific surface area of 336m 2 / Kg. The steel slag added with component adjustment raw materials was calcined in a silicon-molybdenum rod furnace at 1600°C, and the firing temperature was 1300°C. After the calcination is completed, the optimized steel slag is obtained through water cooling at the slag outlet, rapid cooling, granulation, and grinding.

[0029] After the above optimized treatment, the f-CaO content of the steel slag is about 1.8%, the pressure steaming stability is qualified, and the 28-day activity index is about 87.6%.

Embodiment 3

[0031] Add components to the original steel slag to adjust the raw materials limestone (2.27% as CaO), clay (2.27% as SiO 2 Calculated as 4.28%) and bauxite (as Al 2 O 3 Calculated as 1.20%), mixed and ground together to a specific surface area of 336m 2 / Kg. The steel slag added with component adjustment raw materials was calcined in a silicon-molybdenum rod furnace at 1600°C, and the firing temperature was 1300°C. After the calcination is completed, the optimized steel slag is obtained through air cooling at the slag outlet, rapid cooling, granulation, and grinding.

[0032] After the above optimized treatment, the f-CaO content of the steel slag is about 1.0%, the pressure steaming stability is qualified, and the 28-day activity index is about 85.2%.

[0033] Compared with the original steel slag, the optimized steel slag prepared in the above-mentioned embodiments 1, 2 and 3 has a performance comparison in Table 1:

[0034] Table 1 Comparison of main physical proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com