Halogen-free flame-retardant rigid polyurethane foamed plastic and preparation method for same

The technology of rigid polyurethane and foamed plastics is applied in the fields of polyurethane foamed plastics, halogen-free flame-retardant rigid polyurethane foamed plastics and their preparation, and can solve the problems of complex production process of flame-retardant polyols, long synthesis period and high cost, Achieve good synergistic flame retardant effect, simple product manufacturing process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The raw materials used to prepare halogen-free flame-retardant rigid polyurethane foam are shown in Table 1:

[0044] Table 1

[0045] components

raw material name

parts by weight

polyol mixture

polyol mixture

100

polyisocyanate

diphenylmethane diisocyanate

105

Compound Flame Retardant

Compound Flame Retardant

20

20

[0046] composite catalyst

composite catalyst

1.0

foam stabilizer

AK8801

2.0

crosslinking agent

Glycerin

1.0

[0047] In Table 1, the composite flame retardant is obtained by compounding dimethyl methylphosphonate and urea with a weight ratio of 1:0.5; the polyol mixture is composed of polyether 4110 and polyether 4110H with a weight ratio of 2.5:1, The details are shown in Table 6; the composite catalyst is obtained by compounding a triethylenediamine solution with a weight ratio of 1.5:1 and dibut...

Embodiment 2

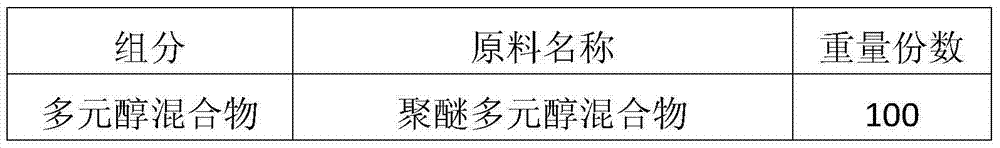

[0054] The raw materials used to prepare halogen-free flame-retardant rigid polyurethane foam are shown in Table 2:

[0055] Table 2

[0056] components

raw material name

parts by weight

polyol mixture

polyether polyol blend

100

polyisocyanate

MR‐200

125

Compound Flame Retardant

Compound Flame Retardant

30

water

10

composite catalyst

composite catalyst

1.5

foam stabilizer

AK8802

2.5

[0057] crosslinking agent

1.2

[0058] In Table 2, the composite flame retardant is obtained by compounding triethyl phosphate and urea with a weight ratio of 1:0.8; the polyether polyol mixture is composed of polyether 4110 and polyether 4110H with a weight ratio of 1.5:1, specifically The situation is shown in Table 6; the composite catalyst is obtained by compounding N, N-diethylethanolamine solution and stannous octoate w...

Embodiment 3

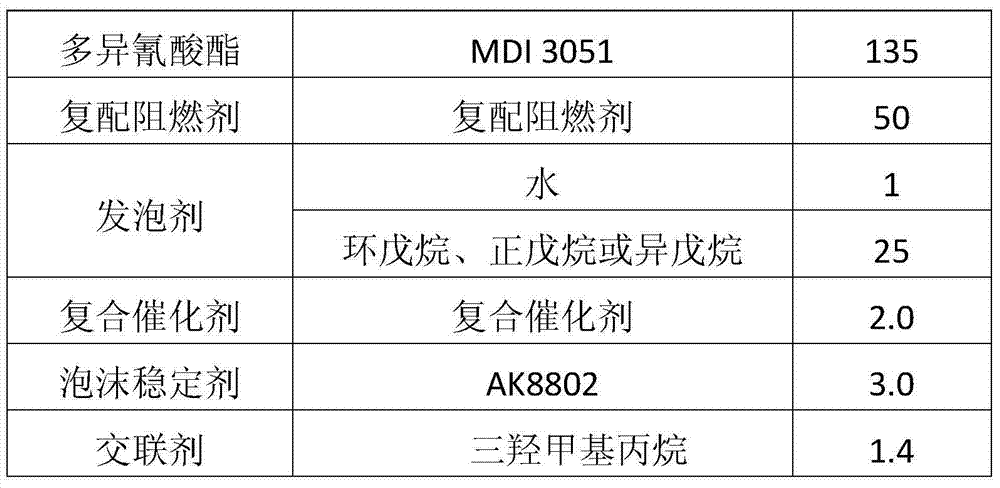

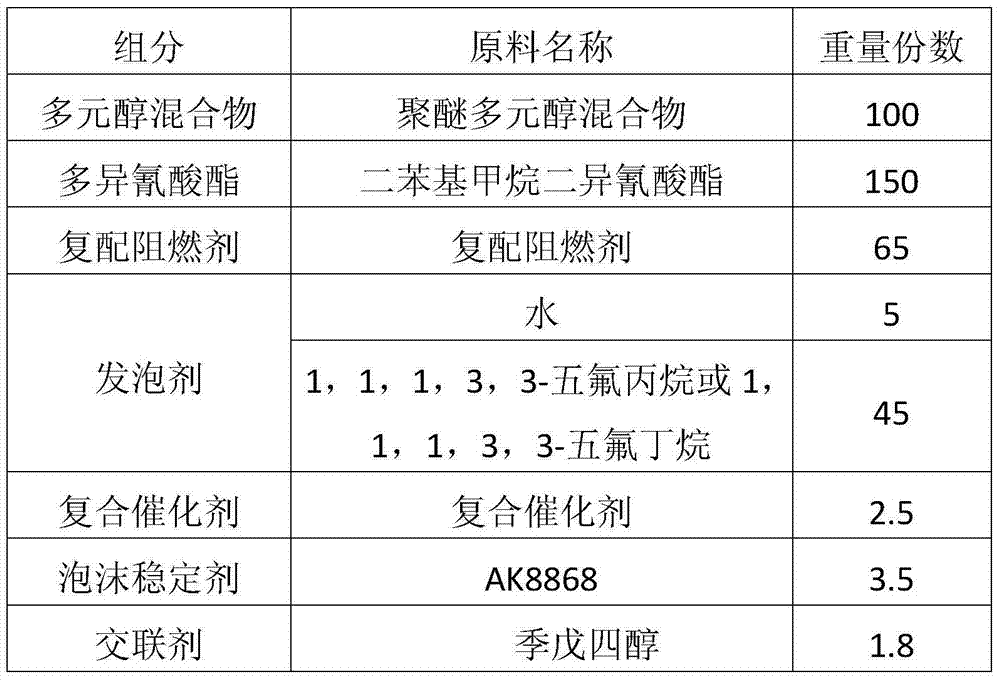

[0070] The raw materials used to prepare halogen-free flame-retardant rigid polyurethane foam are shown in Table 3:

[0071] table 3

[0072]

[0073]

[0074] In Table 3, the compound flame retardant is obtained by compounding triphenyl phosphate and urea with a weight ratio of 1:1.2; the polyether polyol mixture is composed of polyether 4110 and polyether 4110H with a weight ratio of 1:1, specifically The situation is shown in Table 6. The composite catalyst is obtained by compounding a triethanolamine solution with a weight ratio of 3:1 and potassium isooctanoate. The triethanolamine solution is a dipropylene glycol solution with a triethanolamine mass content of 33%.

[0075] MDI3051 basic performance:

[0076] Appearance: colorless transparent liquid

[0077] Density (25°C, g / cm3): 1.22

[0078] NCO content: 33.6%

[0079] Viscosity (25°C, mPa.s): 14

[0080] Vapor pressure (25°C, mmHg): <0.00001

[0081] A preparation method of halogen-free flame-retardant ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com